Concentration cell

A technology of concentration difference battery and ion exchange membrane, which is applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effect of small consumption and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

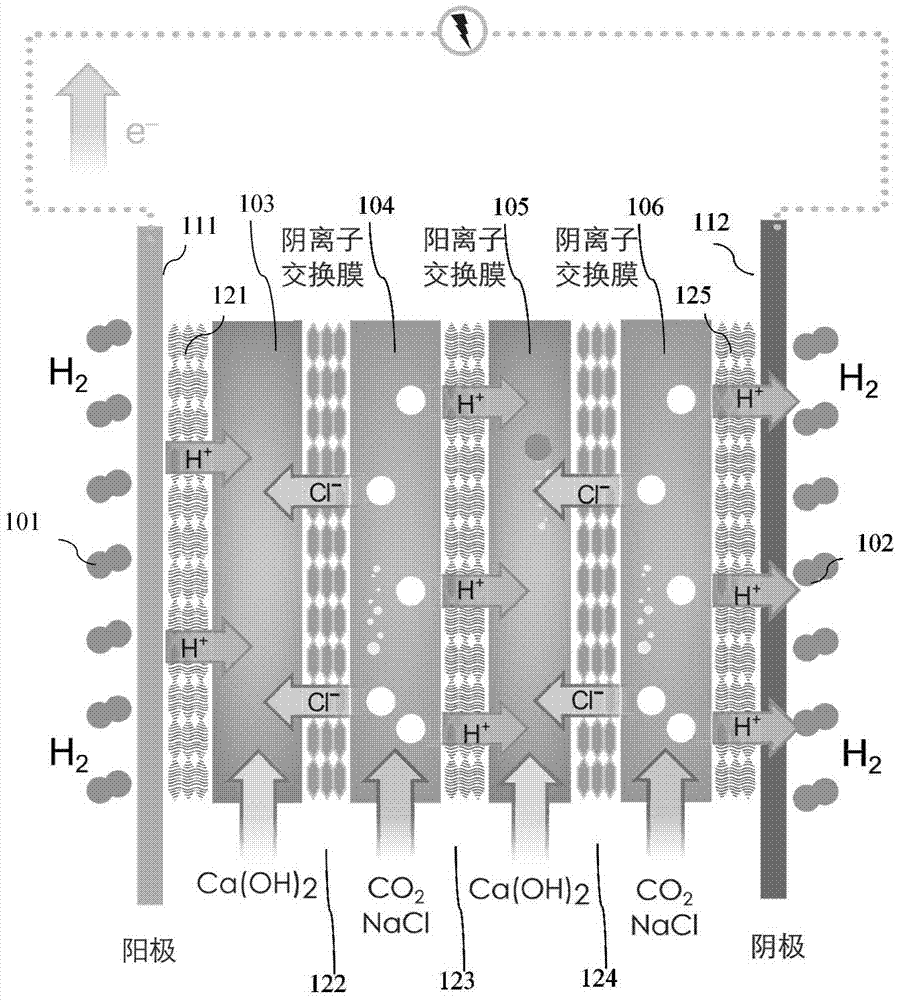

Embodiment 1

[0026] Preparation of gas diffusion electrode: The gas diffusion layer used is TGP-060. It is coated with 0.6mg / cm 2 Carbon powder, PTFE mixture, wherein the mass fraction of PTFE is 30%. The catalyst slurry is then knife-coated over it. The slurry is composed of Pt / C (60% wt. JM Company), Nafion solution with a concentration of 5%, and ethanol; the mass ratio of Nafion, Pt / C, and ethanol is 1:4:20. The gas diffusion electrodes used in the anode and cathode in this embodiment are the same.

[0027] The electrodes prepared above were placed on one side of the cation exchange membrane Nafion-115, and hot-pressed at 120°C and 2,000 pounds of pressure for one minute to form an integrated membrane electrode. The size of the electrodes used in this embodiment is 7cm×7cm. In this embodiment, the anode film electrode (referring to figure 1 111 and 121 in ) and cathode membrane electrode (referring to figure 1 112 and 125 in ) are the same.

[0028] The stainless steel end plate...

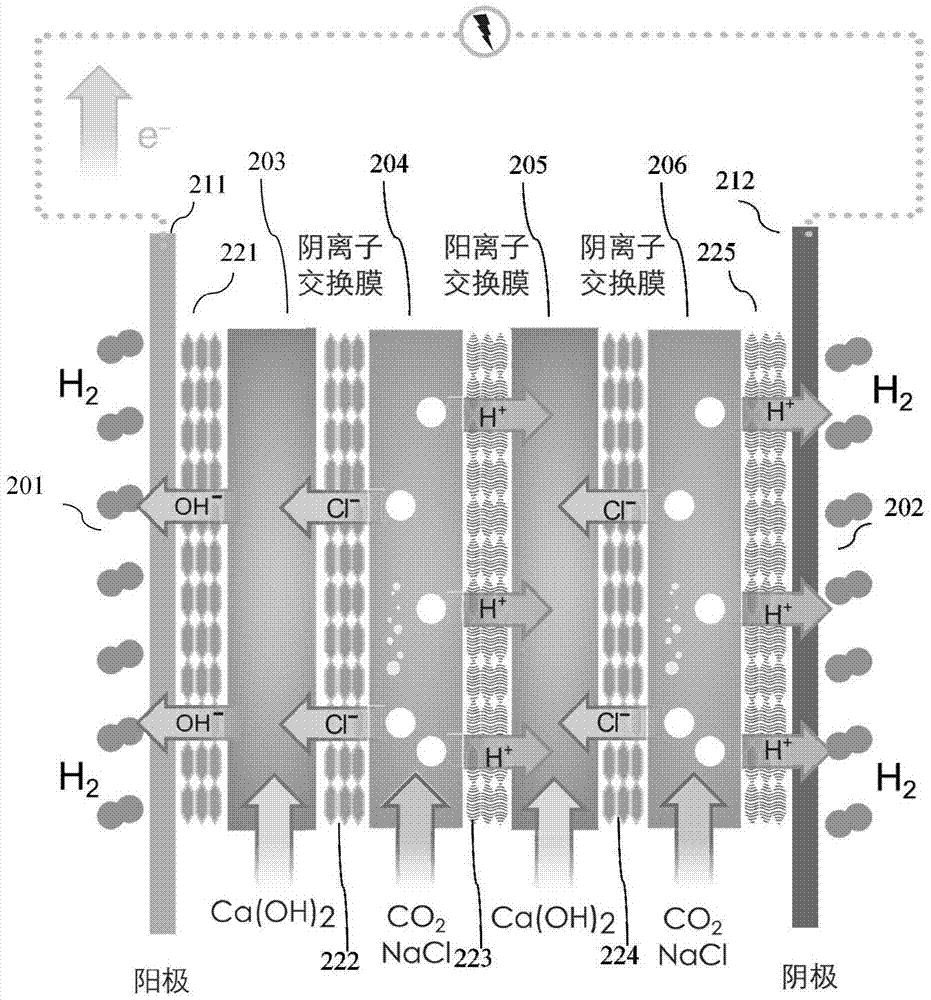

Embodiment 2

[0029] Preparation of gas diffusion electrode: The gas diffusion layer used is TGP-060. It is coated with 0.6mg / cm 2 Carbon powder, PTFE mixture, wherein the mass fraction of PTFE is 30%. The catalyst slurry is then knife-coated over it. The slurry is composed of Pt / C (60% wt. JM Company), Nafion solution with a concentration of 5%, and ethanol; the mass ratio of Nafion, Pt / C, and ethanol is 1:4:20. The gas diffusion electrodes used in the anode and cathode in this embodiment are the same.

[0030] Anode membrane electrode preparation (referring to Figure II 211 and 221 in ): the electrode prepared above was placed on the side of the anion exchange membrane FAA-3-PK-130, and hot-pressed at 120°C and 2000 pounds of pressure for one minute to form an integrated membrane electrode. The size of the electrodes used in this embodiment is 7cm×7cm.

[0031] Cathodic membrane electrode preparation (referring to Figure II 212 and 225 in ): Place the electrode prepared above on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com