Novel totally-dissolved air high-pressure vortex air floatation method and device

A high-pressure swirl and air flotation technology, applied in separation methods, chemical instruments and methods, flotation water/sewage treatment, etc., can solve the problems of low processing load, low dissolved gas efficiency, low efficiency, etc. High, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

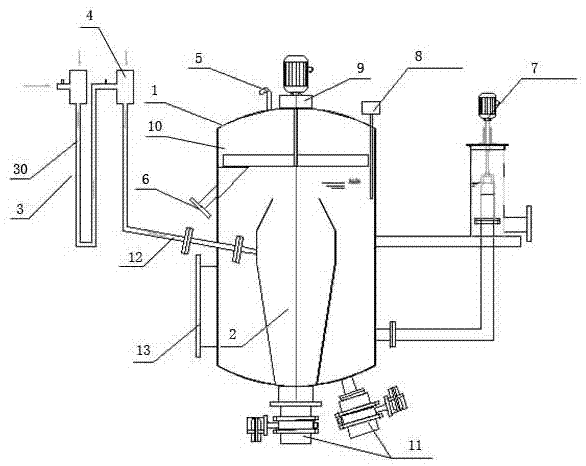

[0048] refer to figure 1 , a new high-pressure cyclone air flotation method with fully dissolved air, the steps of which are:

[0049] 1. After the oily sewage is fully fused with the high-pressure air in the three-phase mixer 4 through the reaction system 3, a vortex is generated inside the three-phase mixer 4, and a preliminary pre-swirl is performed.

[0050] 2. After passing through the swirling flow of the 6-stage three-phase mixer 4, it enters the air flotation tank 1 along the tangential direction, and the swirling flow inner cylinder 2 generates a swirling flow for internal swirling flow. The inflow pipe 12 forms an angle of 10° with the horizontal plane down.

[0051] 3. The upper part of the swirl inner cylinder gradually shrinks. Under the action of swirling flow, the particle size of oil droplets increases, and at the same time, due to the decrease of air pressure, dissolved air is released to produce microbubbles. Under the action of microbubbles, the oil dropl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com