Sand stabilizing method based on magnesium phosphate cement as binder

A technology of magnesium phosphate cement and sand-fixing method, which is applied in the field of desertification control, can solve the problems of short lifespan, secondary pollution, and poor effect of sand-prevention and sand-fixation materials, and achieve the goal of saving the cost of sand prevention and control, simple and convenient construction, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

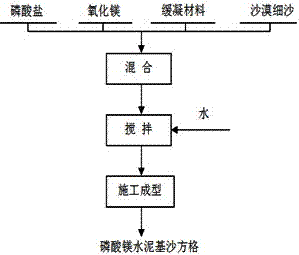

[0026] A kind of method for fixing sand based on magnesium phosphate cement as binder, is characterized in that, comprises the following steps:

[0027] S1, the NH 4 h 2 PO 4 : boric acid: magnesium oxide: fine sand is prepared in a ratio of 1:0.5:15:30 by weight and fully mixed;

[0028] S2. Stir the mixed material obtained in step s1 with water in a ratio of 3:1 by weight to obtain a magnesium phosphate cement semi-wet material;

[0029] S3. Pile the semi-moist material of magnesium phosphate cement obtained in S2 on the sand dunes to form sand ridges to play the role of sand prevention and sand fixation.

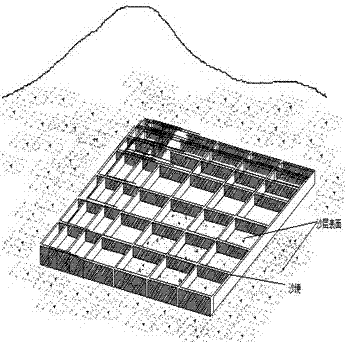

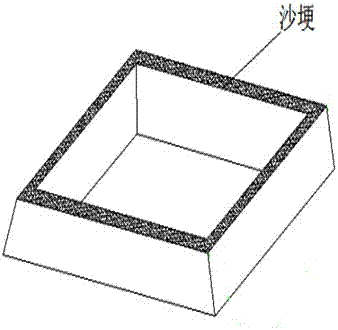

[0030] The sand ridge is as image 3 and 4 As shown, the setting of the sand ridge is as follows figure 2 shown.

Embodiment 2

[0032] A kind of method for fixing sand based on magnesium phosphate cement as binder, is characterized in that, comprises the following steps:

[0033] S1, the NH 4 h 2 PO 4 : boric acid: magnesium oxide: fine sand is prepared in a ratio of 1:0.1:1:10 by weight and fully mixed;

[0034] S2. Stir the mixed material obtained in step s1 and water evenly in a ratio of 2:1 by weight to obtain a semi-wet material of magnesium phosphate cement;

[0035] S3. Pile the semi-moist material of magnesium phosphate cement obtained in S2 on the sand dunes to form sand ridges to play the role of sand prevention and sand fixation.

[0036] The sand ridge is as image 3 and 4 As shown, the setting of the sand ridge is as follows figure 2 shown.

Embodiment 3

[0038] A kind of method for fixing sand based on magnesium phosphate cement as binder, is characterized in that, comprises the following steps:

[0039] S1, the NH 4 h 2 PO 4 : boric acid ester: magnesium oxide: fine sand is prepared according to the ratio of 1:0.5:15:30 by weight and fully mixed;

[0040] S2. Stir the mixture obtained in step s1 and water evenly in a ratio of 1.66:1 by weight to obtain a magnesium phosphate cement semi-wet material;

[0041] S3. Pile the semi-moist material of magnesium phosphate cement obtained in S2 on the sand dunes to form sand ridges to play the role of sand prevention and sand fixation.

[0042] The sand ridge is as image 3 and 4 As shown, the setting of the sand ridge is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com