A method for rapid synthesis of hierarchically porous zif-8 materials

A technology of ZIF-8 and multi-level pores, which is applied in the field of rapid synthesis of multi-level pore ZIF-8 materials, can solve the problems of easy collapse of the skeleton and interpenetration of the frames, and achieve the effects of avoiding heating, stable structure, and rich channel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, 0.67g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20ml methanol and stirred for 15 minutes; 0.164g 2-methylimidazole was dissolved in 20ml methanol and stirred for 15 minutes; Zn(NO 3 ) 2 ·6H 2 Add the O methanol solution into the 2-methylimidazole methanol solution, and continue to stir for 5 minutes; add 0.32 g of diethanolamine to the mixed solution obtained above, and after stirring for 1 minute, suction-filter the resulting product; put the suction-filtered product into a vacuum drying oven at 150°C Drying in middle temperature for 12h prepared a hierarchical porous ZIF-8 material, marked as sample A1.

Embodiment 2

[0033] At room temperature, 0.68g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20ml methanol and stirred for 20 minutes; 0.156g 2-methylimidazole was dissolved in 20ml methanol and stirred for 20 minutes; Zn(NO 3 ) 2 ·6H 2 Add O methanol solution into 2-methylimidazole methanol solution, and continue to stir for 10 minutes; add 0.34g diethanolamine to the above mixed solution, stir for 1min, then filter the product with suction; put the filtered product in a vacuum drying oven at 150°C Drying in middle temperature for 10h prepared a hierarchical porous ZIF-8 material, marked as sample A2.

Embodiment 3

[0035] At room temperature, 0.67g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20ml methanol and stirred for 18 minutes; 0.172g 2-methylimidazole was dissolved in 20ml methanol and stirred for 18 minutes; Zn(NO 3 ) 2 ·6H 2 Add the O methanol solution into the 2-methylimidazole methanol solution, and continue to stir for 8 minutes; add 0.30 g of diethanolamine to the above-mentioned mixed solution, and after stirring for 1 minute, suction-filter the resulting product; put the suction-filtered product into a vacuum drying oven at 150°C Drying in middle temperature for 10h prepared a hierarchical porous ZIF-8 material, marked as sample A3.

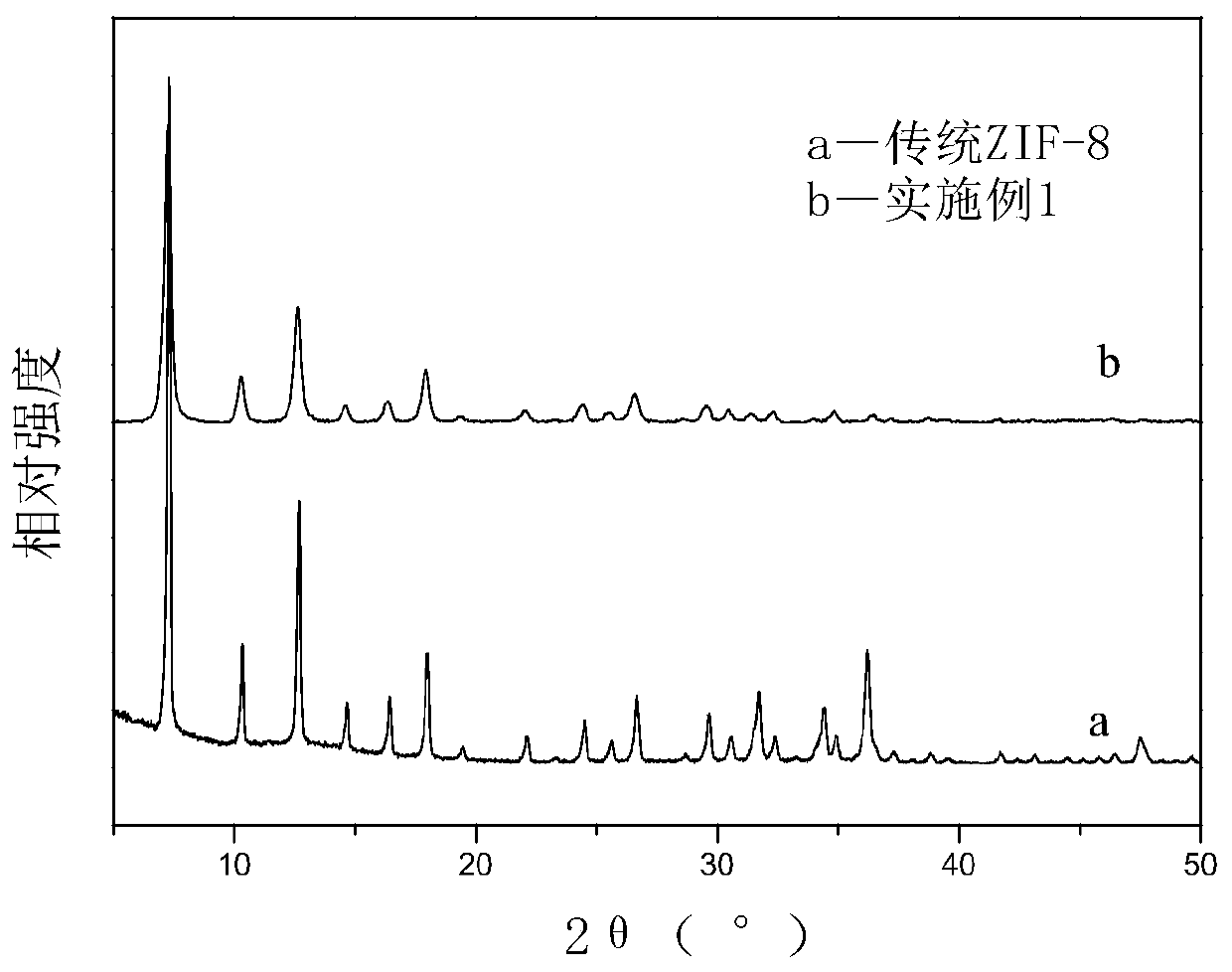

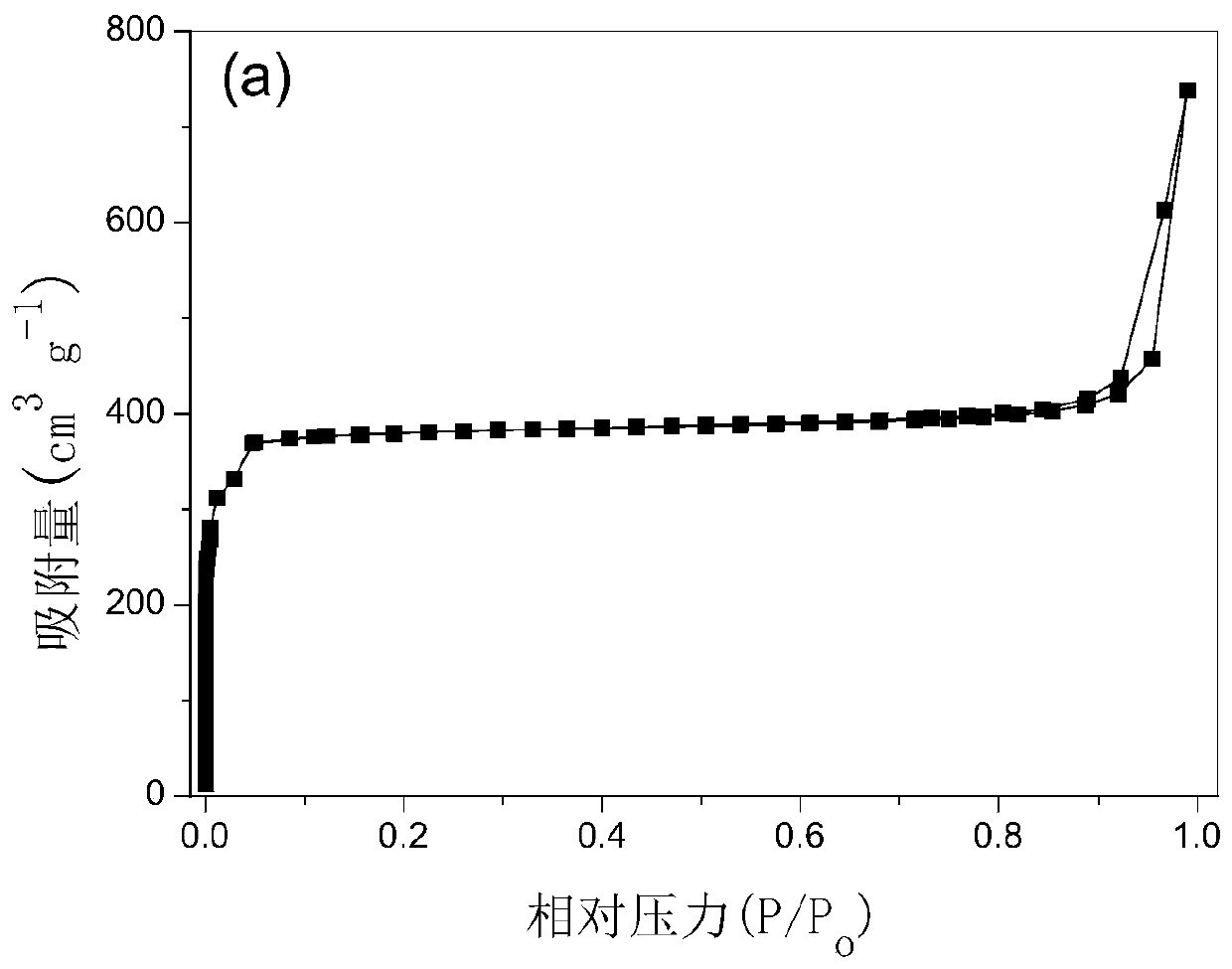

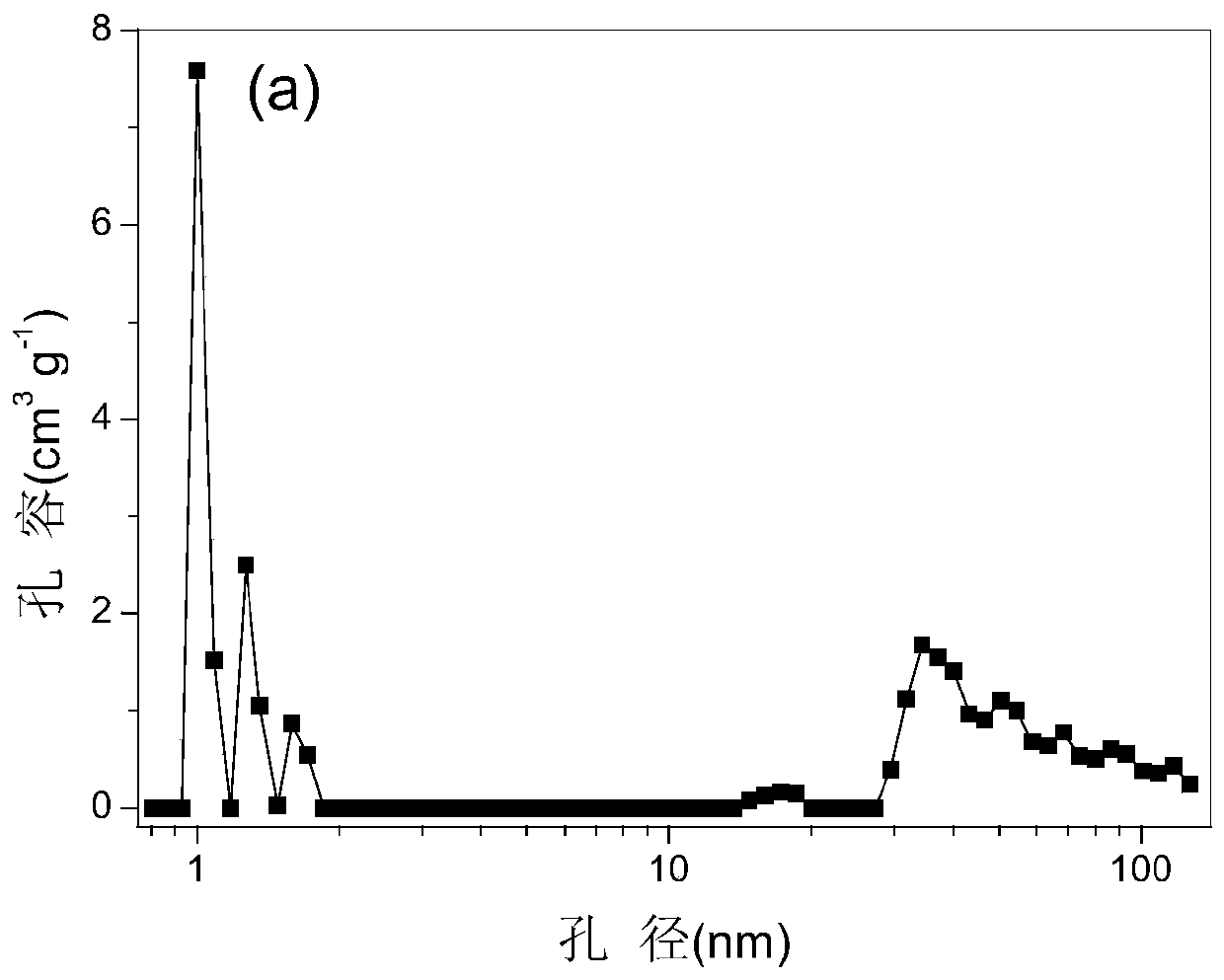

[0036] Taking the characterization result of the hierarchical porous ZIF-8 material prepared in Example 1 as a representative to analyze the effects of the present invention, the analytical results of the hierarchical porous ZIF-8 material prepared in other embodiments are basically the same as those in Example 1, not one by one. supply.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com