Ship level monitoring system

A liquid level monitoring and ship technology, which is applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of complex structure of radar liquid level sensors, inability to measure, and influence on measurement accuracy, so as to avoid drastic changes in liquid level in liquid tanks, Eliminate fire or explosion and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

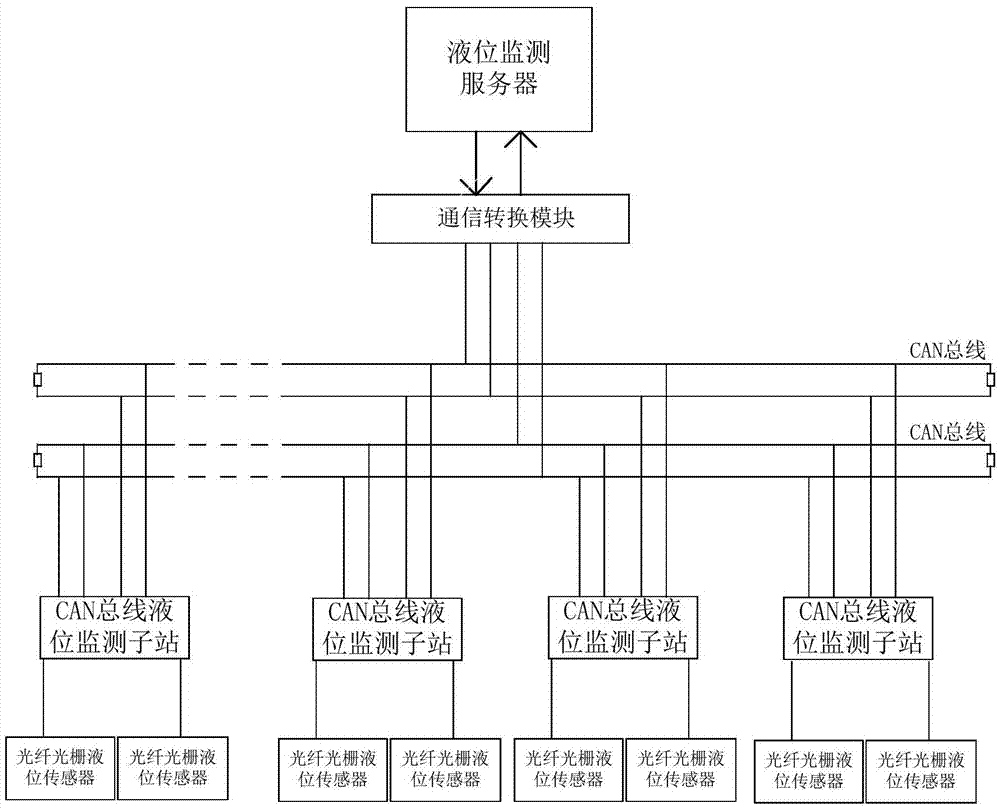

[0025] figure 1 A schematic diagram of the ship's liquid level monitoring system is given, including liquid level monitoring server, communication conversion module, CAN bus liquid level monitoring substation, and fiber optic grating liquid level sensor. The CAN network with dual network redundant structure is used as the communication medium between the liquid level monitoring server and the CAN bus liquid level monitoring substation. The liquid level monitoring server is installed in the cab, and the operator can monitor the liquid level of each liquid tank in real time. The communication conversion module is connected to the CAN bus, and the CAN bus liquid level monitoring sub-station 3 is installed in a safe area. The optical fiber grating liquid level sensor is connected to the CAN bus liquid level monitoring sub-station through an optical cable, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com