Non-coating type diffuse reflection film and manufacturing method thereof

A reflective film and functional masterbatch technology, which is applied in nonlinear optics, optics, instruments, etc., can solve problems such as light shadows, and achieve good market prospects, high reflectivity, and strong competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the non-coating diffuse reflective reflective film provided by the invention comprises the following steps:

[0041] The preparation method comprises the following steps: (1) granulation: uniformly mix polyester resin, inorganic particles and antistatic agent and carry out kneading and granulation to obtain polyester functional masterbatch A; polyester resin, incompatible resin, Toughening resin, chain extender, nucleating agent, antioxidant and dispersant are mixed uniformly and mixed and granulated to obtain polyester functional masterbatch B; (2) cast sheet: polyester resin, polyester functional masterbatch A is mixed according to the proportion as layer A; polyester resin and polyester functional masterbatch B are mixed according to the proportion as layer B. Use two extruders to carry out ABA three-layer co-extrusion melt plasticization, cast cast sheet; (3) Stretch into film: carry out longitudinal stretching, transverse stretching, heat ...

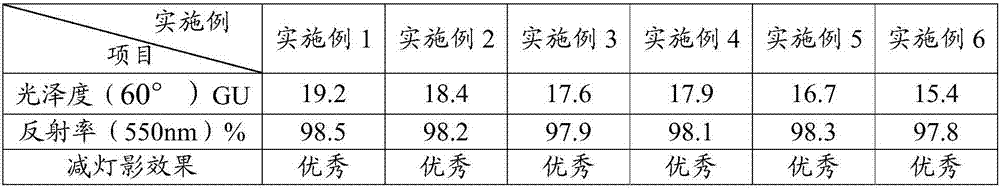

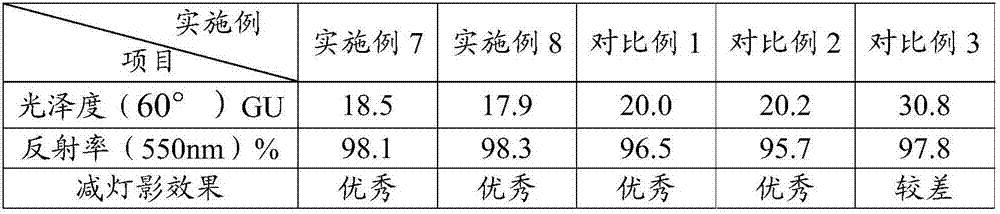

Embodiment 1

[0047] Prepare non-coating diffuse reflective reflective film according to the above method, functional masterbatch A is 94.5% PET chips (intrinsic viscosity 0.68dL / g), 5% silicon dioxide (6.0 μm particle size) and 0.5% ethoxylated laurel amides. Functional masterbatch B is 80.5% PET chips (intrinsic viscosity 0.68dL / g), 10% polymethylpentene, 5% MAH grafted SEBS (grafting rate ≥ 0.5%), 2% BDO, 0.5% 2,2 - sodium methylene-bis(4,6-di-tert-butylphenyl) phosphate, 0.5% antioxidant 1010, 0.5% polytetrahydrofuran ether (molecular weight 2000). Among them, functional masterbatch A accounts for 90% of layer A, and PET chips account for 10% of layer A; functional masterbatch B accounts for 50% of layer B, and layer B of PET chips accounts for 50%. The resulting reflective film had a thickness of 188 μm, wherein the thickness of one layer A accounted for 6% of the thickness of the reflective film, and the thickness of the B layer accounted for 88% of the thickness of the reflective fi...

Embodiment 2

[0049] Prepare non-coating diffuse reflective reflective film according to the above method, functional masterbatch A is 89.5% PET chip (intrinsic viscosity 0.68dL / g), 10% calcium carbonate (particle size 1.0 μm) and 0.5% sodium alkylsulfonate . Functional masterbatch B is 78.8% PET chips (intrinsic viscosity 0.68dL / g), 15% cycloolefin copolymer, 3% MAH grafted with POE (grafting rate ≥ 0.5%), 1% 1,6-hexanediol, 1% 1,3:2,4-bis(3,4-dimethyl)benzylidene sorbitol acetal, 1% antioxidant 168, 0.2% polyethylene wax. Among them, functional masterbatch A accounts for 95% of layer A, PET chips account for 5% of layer A; functional masterbatch B accounts for 60% of layer B, and PET chips account for 40% of layer B. The resulting reflective film had a thickness of 188 μm, wherein the thickness of one layer A accounted for 5% of the thickness of the reflective film, and the thickness of the B layer accounted for 90% of the thickness of the reflective film. The related properties of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com