Full-process blowing fan manufacturing quality monitoring system based on process flow

A technology for manufacturing quality and monitoring systems, applied in instruments, data processing applications, resources, etc., can solve problems such as large system information throughput, dirty data, and system performance cannot be guaranteed, to overcome information overlap and improve system parallelism , the effect of saving transaction processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

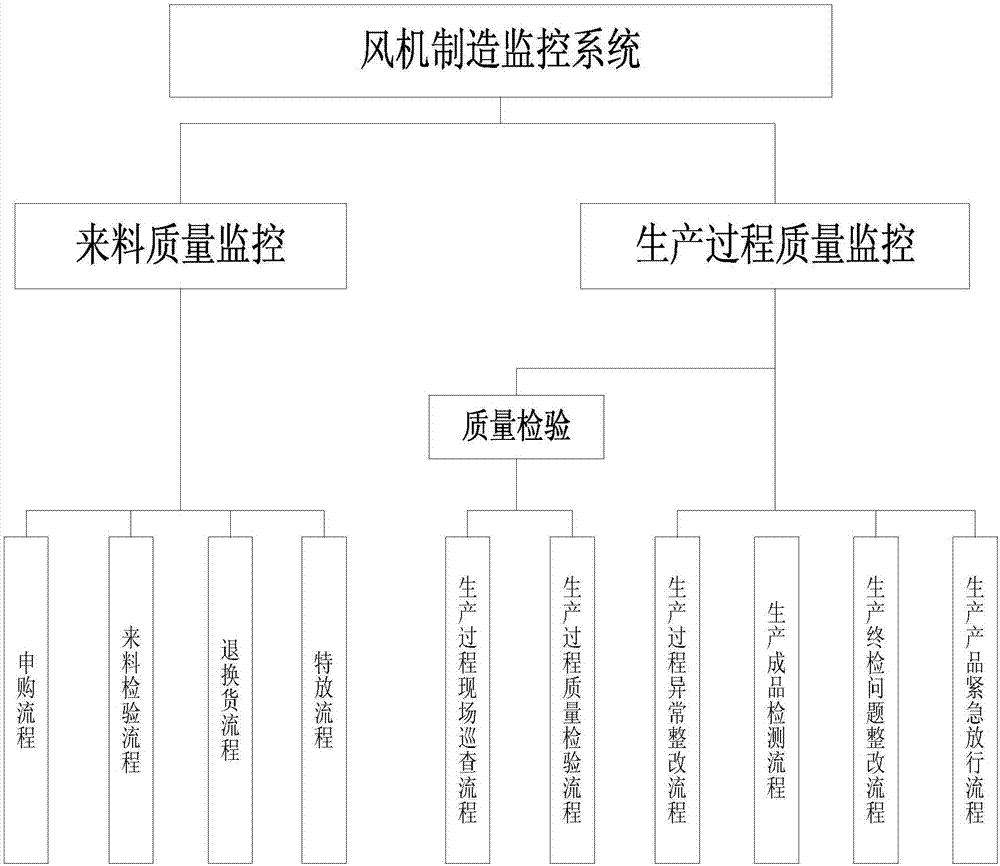

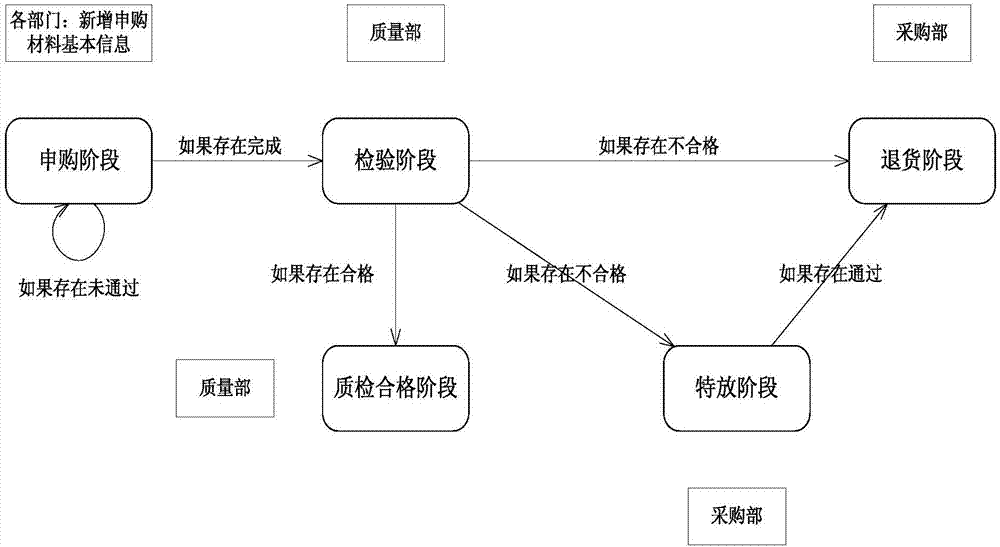

[0029] A whole-process fan manufacturing quality monitoring system based on process flow, the system includes a workflow engine, terminal display device, communication device, and server; among them, the workflow engine is responsible for task assignment and task scheduling; the terminal display device is responsible for users to view pending tasks The process and process history; the communication device is responsible for transmitting information through the network interface; the server is responsible for workflow information processing and data storage. The monitoring system adopts Visual studio.NET integrated development environment, the development language is C#, and the background database uses Microsoft SQL Server 2005. The workflow engine of the system divides the process into two sub-modules: the incoming material quality monitoring module and the production process quality monitoring module. The specific structure is shown in the attached figure 1 As shown, the inc...

Embodiment 2

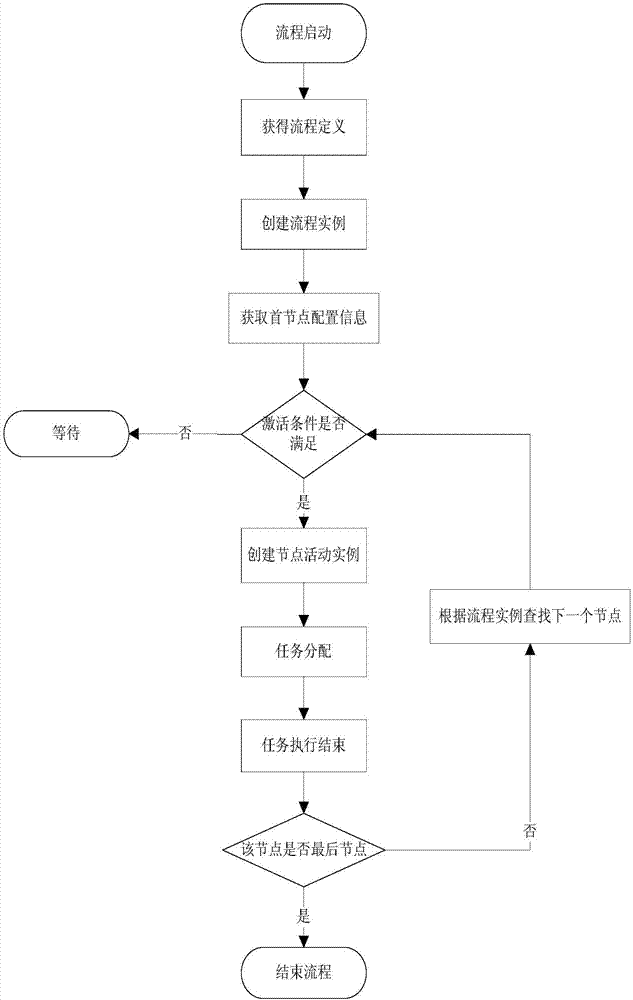

[0031] as attached figure 2 As shown, the figure describes the operation mechanism of the workflow engine designed by this system. The workflow engine is mainly responsible for task assignment and task scheduling, ensuring that the workflow runs normally according to the predefined process sequence. The specific steps are as follows:

[0032] Step 1: After receiving the generating process instruction, get the current process definition according to the process template of the obtained instruction;

[0033] Step 2: Create and initialize a process instance according to the process template information obtained by the engine;

[0034] Step 3: The engine obtains the information of the first node of the process, and checks whether the node meets the activation conditions. If so, it calls the organization model library to assign the task to the corresponding user according to the defined task allocation principle, otherwise it needs to wait for the information of the next first nod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com