Mandrel rod for high-performance post composite insulator and manufacturing method thereof

A composite insulator, high-performance technology, which is applied to the mandrel for high-performance pillar composite insulator and its manufacturing field, can solve the problems of gas and filler leakage, large difference in deformation, short life of the mandrel, etc., and achieves low use cost. , The effect of good bending resistance and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

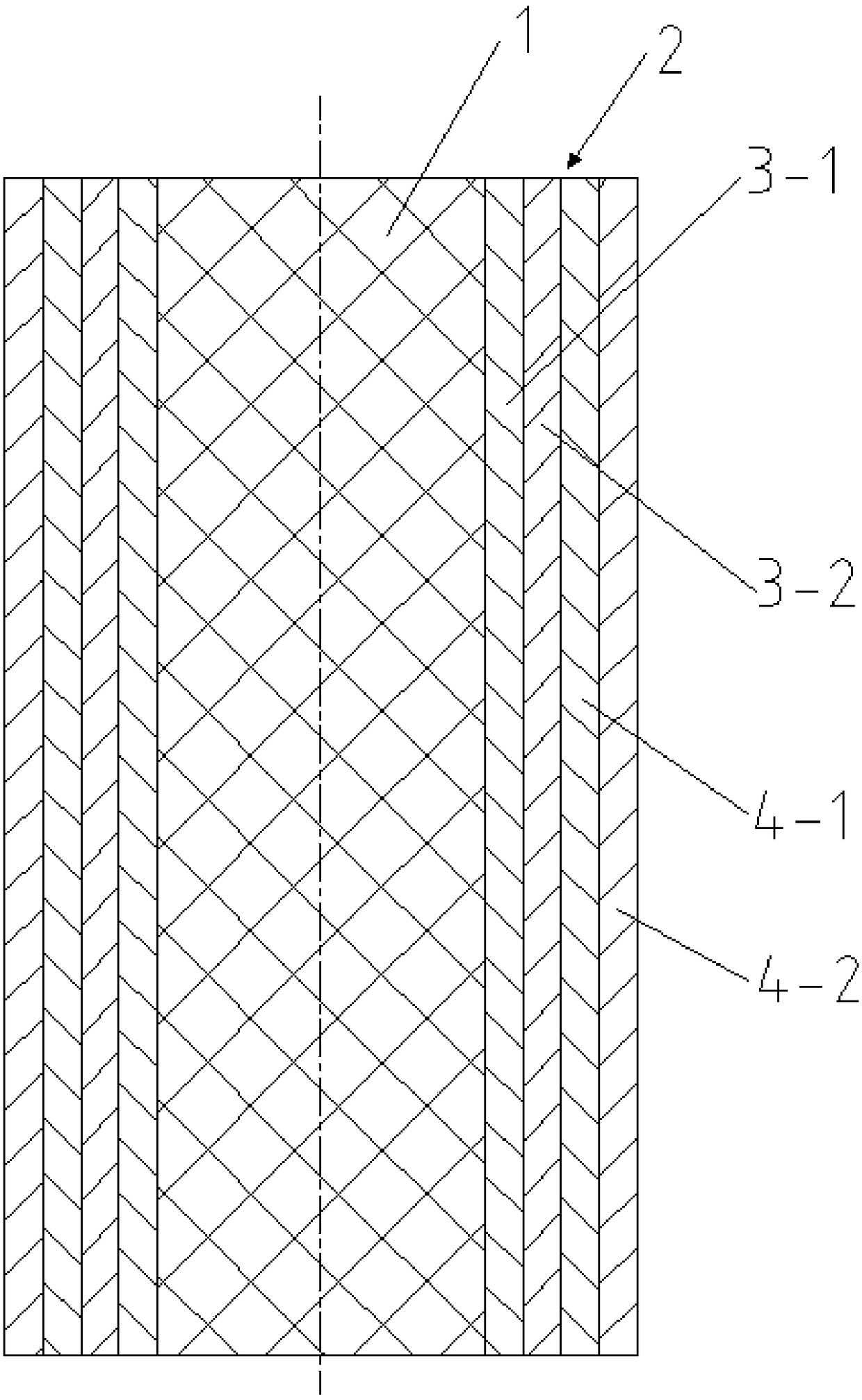

[0032] Such as figure 1 As shown, the high-performance post composite insulator mandrel of the present invention includes an inner mandrel 1 and a winding tube 2 arranged outside the inner mandrel 1, and the winding tube 2 is formed by winding and curing high-strength glass fibers impregnated with epoxy resin glue. The inner mandrel 1 is formed by pouring epoxy resin glue, and the winding tube 2 is composed of a first layer and a second layer, and the first layer and the second layer are both made of epoxy resin. The high-strength glass fibers impregnated with resin glue are wound and cured, the layer thickness of the first layer is 8mm, and the layer thickness of the second layer is 8mm; the epoxy resin glue is made of CYD128 resin, methyl tetra Hydrophthalic anhydride, epoxy toughening agent and dimethylbenzylamine are made according to the mass ratio of 100:80:10:4; the breaking strength of the high-strength glass fiber is not less than 300N.

[0033] In this embodiment, t...

Embodiment 2

[0058] Such as figure 1 As shown, the high-performance post composite insulator mandrel of the present invention includes an inner mandrel 1 and a winding tube 2 arranged outside the inner mandrel 1, and the winding tube 2 is formed by winding and curing high-strength glass fibers impregnated with epoxy resin glue. The inner mandrel 1 is formed by pouring epoxy resin glue, and the winding tube 2 is composed of a first layer and a second layer, and the first layer and the second layer are both made of epoxy resin. The high-strength glass fibers impregnated with resin glue are wound and cured, the layer thickness of the first layer is 5mm, and the layer thickness of the second layer is 5mm; the epoxy resin glue is made of CYD128 resin, methyl tetra Hydrophthalic anhydride, epoxy toughening agent and dimethylbenzylamine are made according to the mass ratio of 100:80:10:4; the breaking strength of the high-strength glass fiber is not less than 300N.

[0059] In this embodiment, t...

Embodiment 3

[0078] Such as figure 1 As shown, the high-performance post composite insulator mandrel of the present invention includes an inner mandrel 1 and a winding tube 2 arranged outside the inner mandrel 1, and the winding tube 2 is formed by winding and curing high-strength glass fibers impregnated with epoxy resin glue. The inner mandrel 1 is formed by pouring epoxy resin glue, and the winding tube 2 is composed of a first layer and a second layer, and the first layer and the second layer are both made of epoxy resin. The high-strength glass fibers impregnated with resin glue are wound and cured, the layer thickness of the first layer is 10mm, and the layer thickness of the second layer is 10mm; the epoxy resin glue is made of CYD128 resin, methyl tetra Hydrophthalic anhydride, epoxy toughening agent and dimethylbenzylamine are made according to the mass ratio of 100:80:10:4; the breaking strength of the high-strength glass fiber is not less than 300N.

[0079] In this embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com