Deep-lying karst region water seal reinforced roadbed structure and construction method thereof

A construction method and subgrade technology, applied in infrastructure engineering, roads, roads, etc., can solve the problems of maintaining the long-term stability of the subgrade structure, unable to obtain efficient layout, development and expansion of karst caves, etc., to ensure long-term stability and save construction. Process, effect of removing threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The subgrade structure and implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

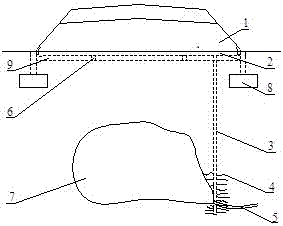

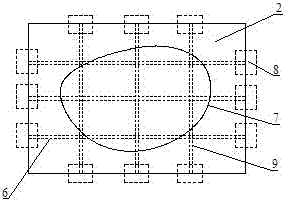

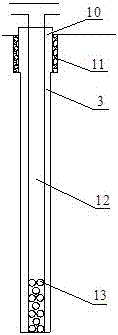

[0014] Such as figure 1 , figure 2 , image 3 Shown, the present invention a kind of subgrade structure and construction method thereof of deep-buried type karst area water-stop reinforcement, this subgrade structure comprises subgrade (1), concrete cast-in-place slab (2), borehole (3), grout radiation area ( 4), water flow (5), prestressed longitudinal beam (6), karst cave (7), independent foundation (8), prestressed beam (9), steel pipe (10), sandstone (11), grouting pipe (12 ), grout radiation holes (13); wherein the prestressed beams (9) and prestressed longitudinal beams (6) are interlaced and arranged in the shape of a "field", and the concrete cast-in-place slabs (2) are poured on the prestressed beams, The independent foundation (8) provides support for the prestressed beam; the grout in the grouting pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com