Silicon crystal floor

A technology of silicon crystal and floor, which is applied in the field of floor, can solve the problems of serious floor aging and poor wear resistance, and achieve the effect of good wear resistance and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

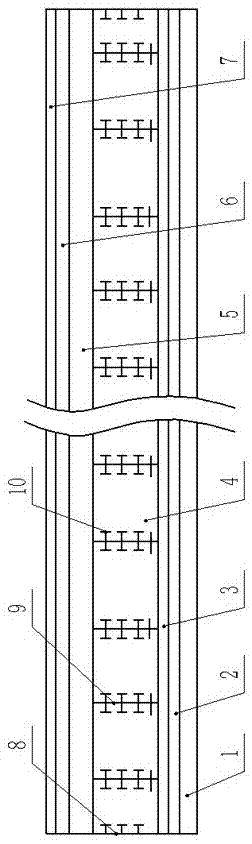

[0028] Such as figure 1 As shown, the silicon crystal floor includes a bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with an emery layer 2, a polyethylene reinforced mesh layer 3, a first-grade concrete layer 4, a graded crushed stone layer 5, Secondary concrete layer 6 and silicon crystal composite layer 7 .

[0029] The bottom slag layer 1 is made of gravel slag, the thickness of the bottom slag layer 1 is 5 mm, the cost is low, and the pressure resistance is strong.

[0030] The corundum layer 2 is smeared by 100-mesh corundum, the thickness of the corundum layer 2 is 5mm, the structure strength is high, and the bearing capacity is strong.

[0031] The polyethylene reinforced mesh layer 3 is a rigid mesh structure processed from polyethylene plastic. The polyethylene reinforced mesh layer 3 has a thickness of 5mm, has high structural strength and is not easily deformed.

[0032] A steel frame 8 is arranged in the...

Embodiment 2

[0047] The difference between the second embodiment and the first embodiment lies in the structure of the silicon crystal floor. The silicon crystal floor includes the bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with an emery layer 2 and a polyethylene reinforcement mesh layer. 3. Primary concrete layer 4, graded crushed stone layer 5, secondary concrete layer 6 and silicon crystal composite layer 7.

[0048] The bottom slag layer 1 is made of gravel slag, the thickness of the bottom slag layer 1 is 10 mm, the cost is low, and the pressure resistance is strong.

[0049]The corundum layer 2 is smeared by 140-mesh corundum, the thickness of the corundum layer 2 is 15mm, the structure strength is high, and the bearing capacity is strong.

[0050] The polyethylene reinforced mesh layer 3 is a rigid mesh structure processed from polyethylene plastic. The polyethylene reinforced mesh layer 3 has a thickness of 12mm, has h...

Embodiment 3

[0057] The difference between the third embodiment and the first embodiment lies in the structure of the silicon crystal floor. The silicon crystal floor includes the bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with an emery layer 2 and a polyethylene reinforcement mesh layer. 3. Primary concrete layer 4, graded crushed stone layer 5, secondary concrete layer 6 and silicon crystal composite layer 7.

[0058] The bottom slag layer 1 is made of gravel slag, the thickness of the bottom slag layer 1 is 8 mm, the cost is low, and the pressure resistance is strong.

[0059] The corundum layer 2 is smeared by 120-mesh corundum, the thickness of the corundum layer 2 is 10mm, the structure strength is high, and the bearing capacity is strong.

[0060] The polyethylene reinforced mesh layer 3 is a rigid mesh structure processed from polyethylene plastic. The polyethylene reinforced mesh layer 3 has a thickness of 10 mm, has h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com