Thermoplastic elastomer cladding material and preparation method thereof

A technology of thermoplastic elasticity and body wrapping, which is applied in the field of polymers, can solve the problems of heavy weight and poor recyclability of coating materials, and achieve the effects of light specific gravity, good environmental performance and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

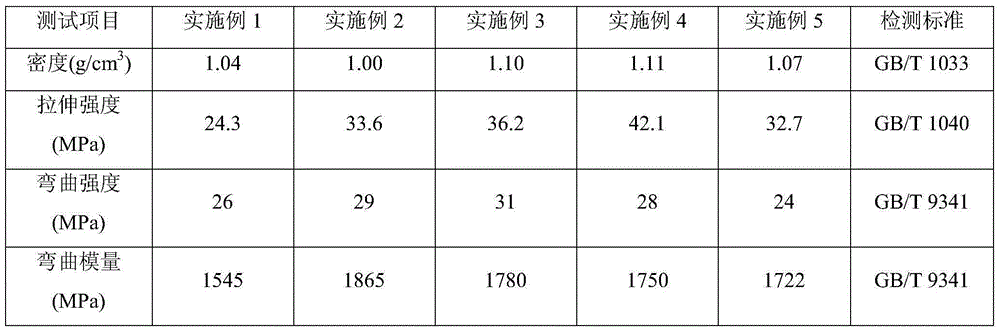

Examples

Embodiment 1

[0030] Take 43Kg of polypropylene, 3Kg of talcum powder, 5Kg of titanium dioxide, 3.5Kg of EVA, 0.6Kg of lubricant, 3.5Kg of anti-ultraviolet agent C813.5Kg, and 1294Kg of antistatic agent, add them to the mixer, and stir and mix evenly at 30°C;

[0031] Put the uniformly mixed raw materials and 4Kg green masterbatch into the extruder, granulate at 110°C, cool with water and blow dry to obtain granules;

[0032] Carboxymethyl cellulose suspension was prepared according to the mass ratio of carboxymethyl cellulose and water at 1:2. After fully soaking 150D and 2Kg chitin fibers into the carboxymethyl cellulose suspension, add lint oil (PP lint oil) ), then plasticizing and extruding, and then cooling by air cooling and water cooling in turn; when air cooling, the outlet air temperature is 33°C; when water cooling, the water temperature is 15°C. Finally, a winding machine is used for winding to obtain a thermoplastic elastomer coating material.

Embodiment 2

[0034] Take 73Kg of polypropylene, 18Kg of fly ash, 25Kg of EPDM, 1Kg of lubricant, 0.1Kg of light stabilizer, and 5Kg of flame retardant, add them to the mixer, and stir and mix evenly at 25°C;

[0035] Put the uniformly mixed raw materials and 6Kg of environmentally friendly blue masterbatch into the extruder, granulate at 100°C, and obtain granules after water cooling and drying;

[0036] Carboxymethyl cellulose suspension was prepared according to the mass ratio of carboxymethyl cellulose and water at 1:5. After fully soaking the carboxymethyl cellulose suspension with 300D, 5Kg hollow fiber (obtained by blending silk and polyester), the increase Thread oil (PP thread oil), then plasticized and extruded, and then cooled by air cooling and water cooling in turn; when air cooling, the outlet air temperature is 30°C; when water cooling, the water temperature is 10°C. Finally, a winding machine is used for winding to obtain a thermoplastic elastomer coating material.

Embodiment 3

[0038] Take 73Kg of polypropylene, 18Kg of fly ash, 25Kg of EPDM, 1Kg of lubricant, 0.1Kg of light stabilizer, and 5Kg of flame retardant, add them to the mixer, and stir and mix evenly at 25°C;

[0039] Put the uniformly mixed raw materials and 6Kg of environmentally friendly blue masterbatch into the extruder, granulate at 100°C, and obtain granules after water cooling and drying;

[0040] Carboxymethylcellulose suspension was prepared according to the mass ratio of carboxymethylcellulose to water 1:5, 300D, 4KgPP fibers were plasticized and extruded, and then cooled by air cooling and water cooling in turn; The wind temperature is 30°C; when water cooling, the water temperature is 10°C. Finally, a winding machine is used for winding to obtain a thermoplastic elastomer coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com