Production method of warp knitting raising interior decorative material of automobile

A technology for automobile interior decoration and production method, which is applied in the directions of warp knitting, upper structure sub-assembly, heating/cooling fabric, etc., can solve the problems of insufficient energy saving and environmental protection in the production process, heavy product weight, and difficulty in demoulding, etc. Prolonged aging time, good dimensional stability, and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Production of interior car roof materials

[0032] Raw material selection: 75D / 36F polyester semi-gloss low stretch yarn and 50D / 24F semi-gloss polyester filament

[0033] Warping: Use a high-speed warping machine to arrange the raw materials in step a into a pan head that can be used by the warp knitting machine. The warping line speed is controlled at 75D. Low elastic yarn: the line speed is 600m / min, and the tension is controlled at 17-20g / piece; The 50D polyester filament is 400m / min, the tension is controlled at 8-10 g / filament, and the tension of each coil head and filament is adjusted to be uniform;

[0034] c. Weaving: Install the warping head of step b on a Tricot type warp knitting machine, machine number: 28E, and the process parameters of the machine are shown in Table 1.

[0035] Table 1 Process parameters

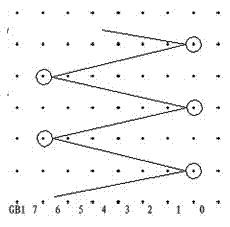

[0036] comb order threading method penetrate raw material Laying law Front comb (GB1) fu...

Embodiment 2

[0042] Example 2: Production of automotive interior trunk top cover materials

[0043] Raw material selection: 50D / 24F cationic semi-gloss polyester filament and 75D / 36F polyester semi-gloss low stretch yarn

[0044] b. Warping: Use a high-speed warping machine to arrange the raw materials in step a into a pan head that can be used by the warp knitting machine. The warping line speed is controlled at 75D. root; 50D polyester filament 400m / min, the tension is controlled at 8-10 g / thread, and the tension of each coil head and filament is adjusted to be uniform;

[0045] c. Weaving: install the warping head of step b on a Tricot type warp knitting machine, machine number: 28E, and the process parameters of the machine are shown in Table 2;

[0046] Table 2 Process parameters

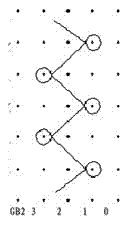

[0047] comb order threading method penetrate raw material Laying law Front comb (GB1) full wear Polyester semi-gloss low stretch yarn 1-0 / 5-6 / / Middle comb (GB2) full w...

Embodiment 3

[0053] Example 3: Production of two-color automotive interior roof materials

[0054] a. Selection of raw materials: 50D / 24F cationic semi-gloss polyester filament and 75D / 36F polyester semi-gloss low-elasticity yarn;

[0055] b. Warping: Use a high-speed warping machine to arrange the raw materials in step a into a pan head that can be used by the warp knitting machine. The warping line speed is controlled at 75D. root; 50D polyester filament 400m / min, the tension is controlled at 8-10 g / thread, and the tension of each coil head and filament is adjusted to be uniform;

[0056] c. Weaving: Install the warping head of step b on a Tricot type warp knitting machine, machine number: 28E, and the process parameters of the machine are shown in Table 3.

[0057] Table 3 process parameters

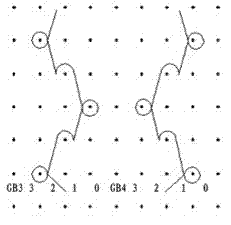

[0058] comb order threading method penetrate raw material Laying law Front comb (GB1) full wear Polyester semi-gloss low stretch yarn 1-0 / 6-7 / / Middle comb (GB2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com