A fiber grating sensor for measuring the deformation of arc-shaped components and its measuring method

A fiber grating and sensor technology, which is applied in the field of fiber grating sensing, can solve problems such as stress and strain of difficult arc-shaped curved surface components, poor resistance to external electromagnetic interference, and impact on measurement accuracy, so as to achieve long service life and improve post-monitoring efforts And safety factor, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

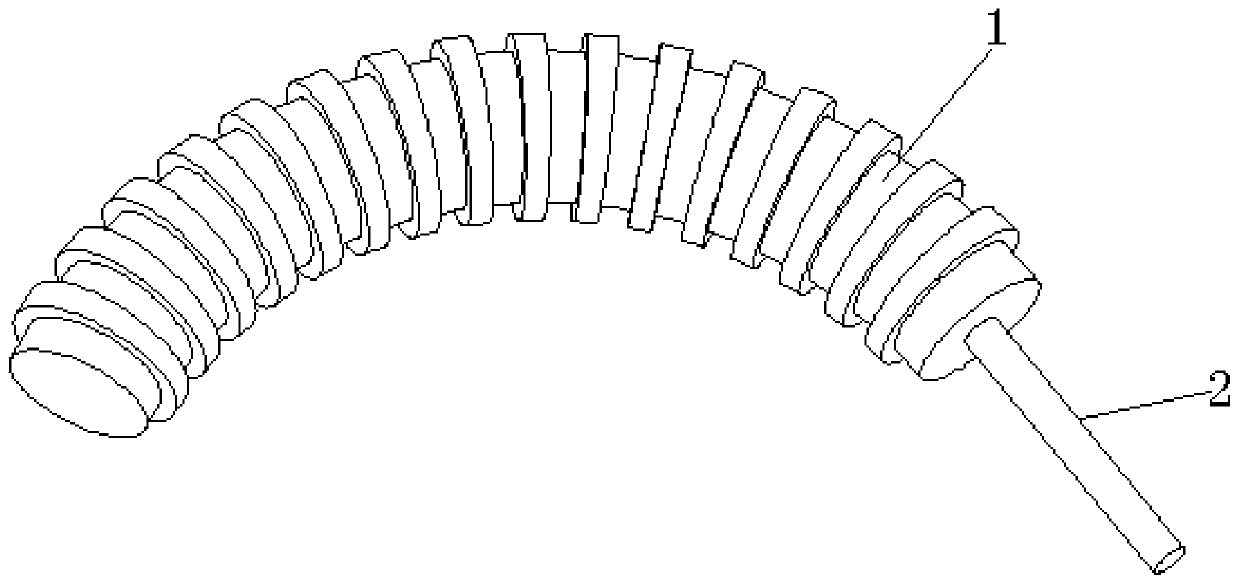

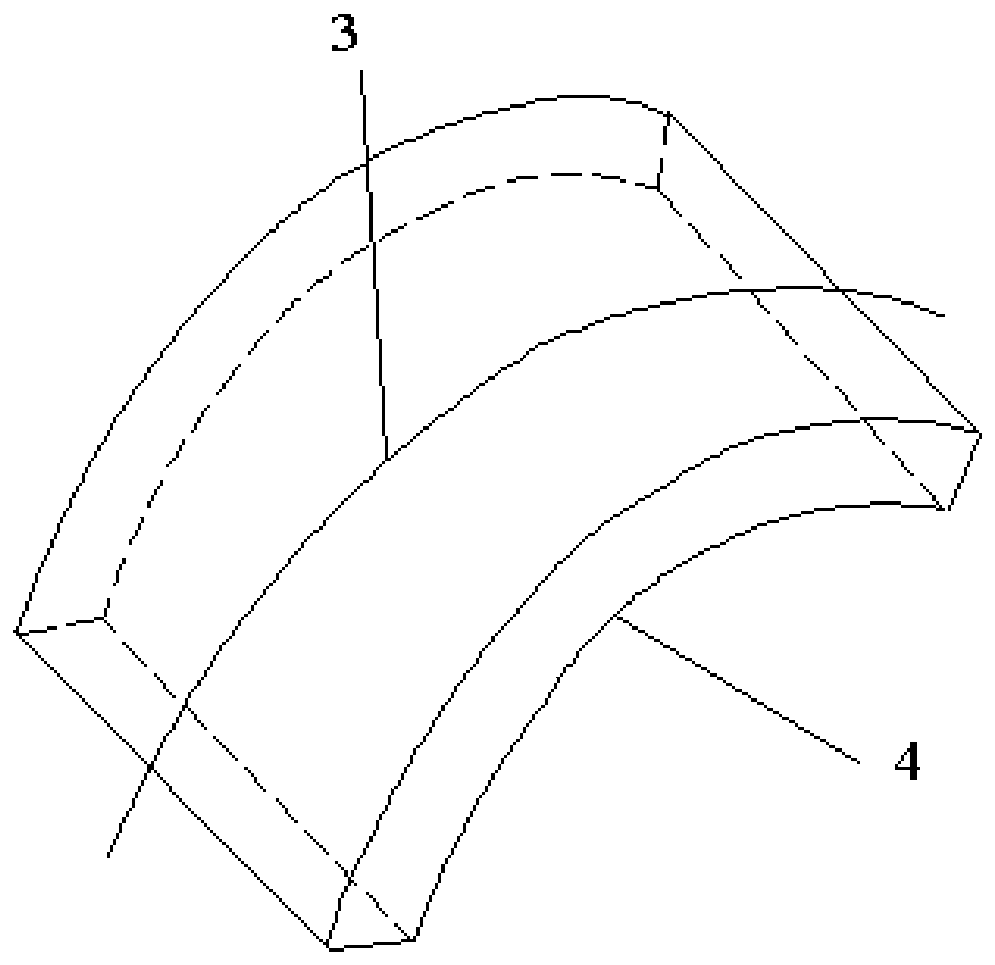

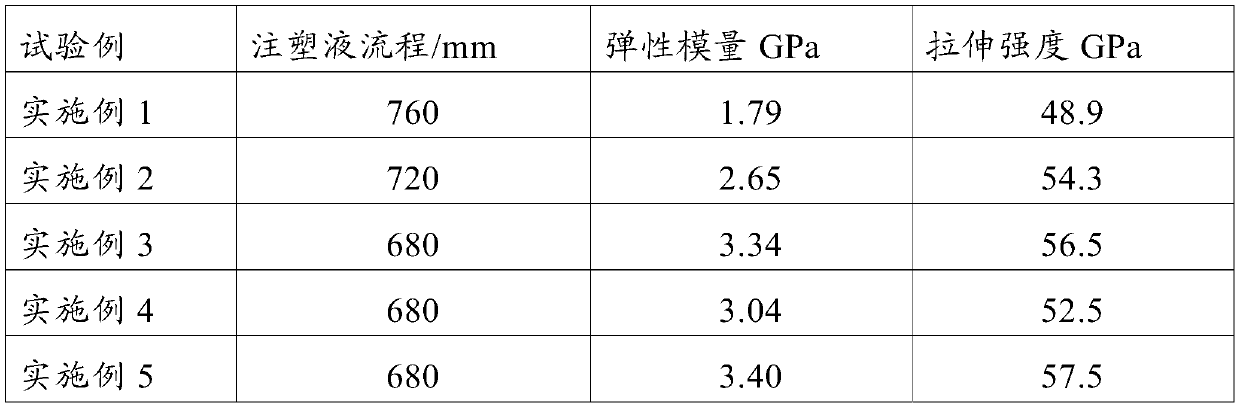

[0026] A fiber grating sensor for measuring the deformation of an arc-shaped member, comprising a fiber grating 2 and a protective material 1 coated outside, the fiber grating sensor 3 is arc-shaped, and groove patterns are arranged on the surface of the protective material 1; the preparation of the The protective material includes the following raw materials: unsaturated polyester resin, quartz sand, basalt fiber, curing agent and accelerator; the parts by weight of each raw material are: 100 parts of unsaturated polyester resin, 20 parts of quartz sand, 1 part of curing agent, and accelerator 0.5 parts; the volume of the basalt fiber is 0.2% of the volume of the unsaturated polyester resin; the particle size of the quartz sand is 75 μm; the length of the basalt fiber is 5 mm and the diameter is 14 μm.

Embodiment 2

[0028] A fiber grating sensor for measuring the deformation of an arc-shaped member, comprising a fiber grating 2 and a protective material 1 coated outside, the fiber grating sensor 3 is arc-shaped, and groove patterns are arranged on the surface of the protective material 1; the preparation of the The protective material includes the following raw materials: unsaturated polyester resin, quartz sand, basalt fiber, curing agent and accelerator; the parts by weight of each raw material are: 100 parts of unsaturated polyester resin, 40 parts of quartz sand, 2.5 parts of curing agent, accelerator 1.25 parts; the volume of the basalt fiber is 0.6% of the volume of the unsaturated polyester resin; the particle size of the quartz sand is 60 μm; the length of the basalt fiber is 7mm and the diameter is 18um.

Embodiment 3

[0030] A fiber grating sensor for measuring the deformation of an arc-shaped member, comprising a fiber grating 2 and a protective material 1 coated outside, the fiber grating sensor 3 is arc-shaped, and groove patterns are arranged on the surface of the protective material 1; the preparation of the The protective material includes the following raw materials: unsaturated polyester resin, quartz sand, basalt fiber, curing agent and accelerator; the parts by weight of each raw material are: 100 parts of unsaturated polyester resin, 30 parts of quartz sand, 2 parts of curing agent, accelerator 1 part; the volume of the basalt fiber is 0.6% of the volume of the unsaturated polyester resin; the particle size of the quartz sand is 50 μm; the length of the basalt fiber is 6 mm and the diameter is 16 um.

[0031] The preparation method of the fiber grating sensor in any one of the above-mentioned embodiments 1 to 3 comprises the following steps:

[0032] S1. Add unsaturated polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com