Friction wear simulation experiment machine of continuous casting crystallizer

A continuous casting mold, friction and wear technology, used in instruments, scientific instruments, testing wear resistance, etc., can solve the problems of complex, harsh, and impacted mold conditions, and achieve high practical application value, convenient operation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

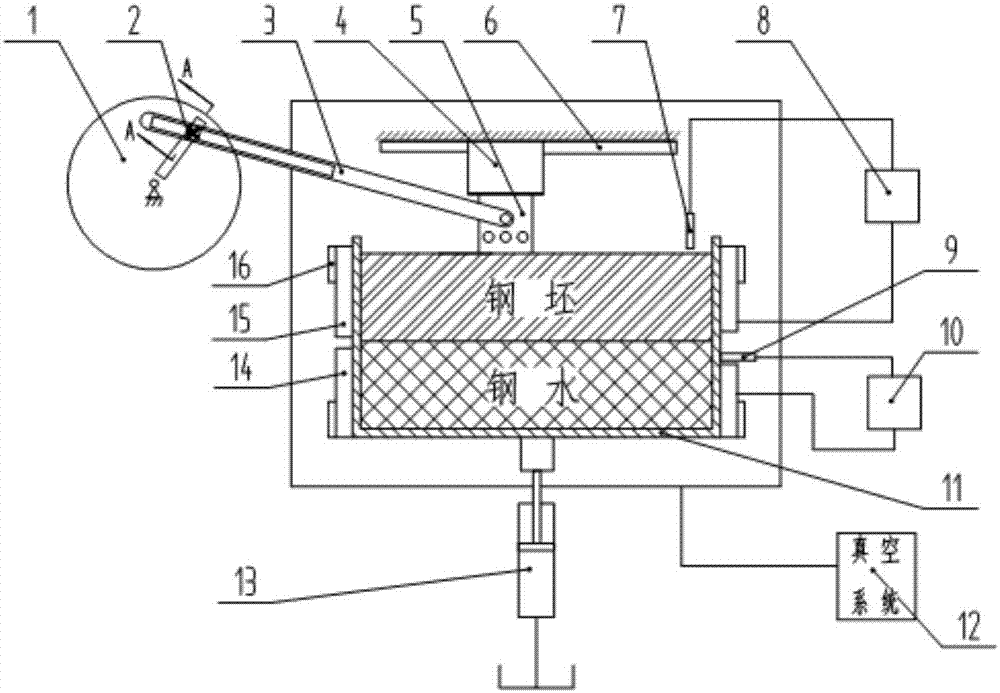

[0013] figure 1 The invention discloses a friction and wear simulation test machine for a continuous casting crystallizer.

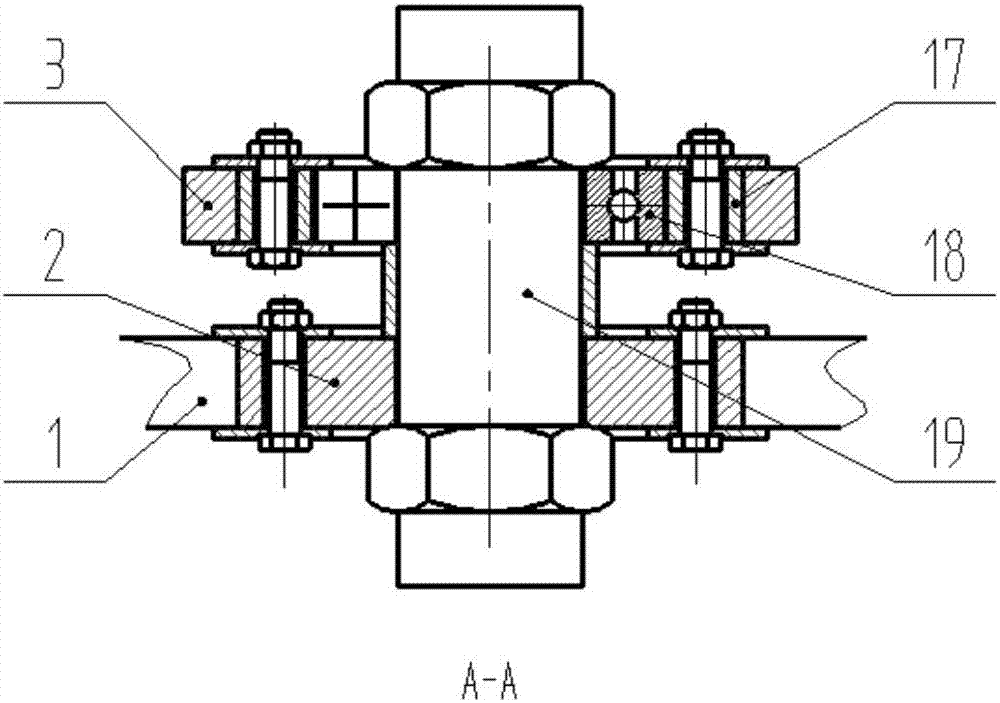

[0014] The drive plate 1, the connecting rod 3 and the continuous casting mold sample 5 form a crank slider mechanism, and the stroke of the crank slider mechanism can be adjusted by the position adjustment block 2 and the slider 17. Among them, the position adjustment block 2 on the drive plate 1 is fixedly connected with the rolling bearing 18 through the pin shaft 19, and the rolling bearing 18 is installed in the chute at one end of the connecting rod 3, and the other end of the connecting rod 3 is connected with the continuous casting mold sample 5 through a hinge. Connection, the continuous casting crystallizer sample 5 and the reciprocating slider 4 are fixedly connected by pins, and can reciprocate on the linear guide rail 6 with the reciprocating slider 4 .

[0015] The temperature control system consists of temperature sensor I7, digital tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com