KPI-based fan manufacturing process-oriented comprehensive quality checking system

A manufacturing process and all-round technology, applied in the direction of manufacturing computing systems, resources, instruments, etc., can solve problems such as large delays, large database overhead, and emission information, and achieve intuitive statistical results, comprehensive systems, and reduced interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

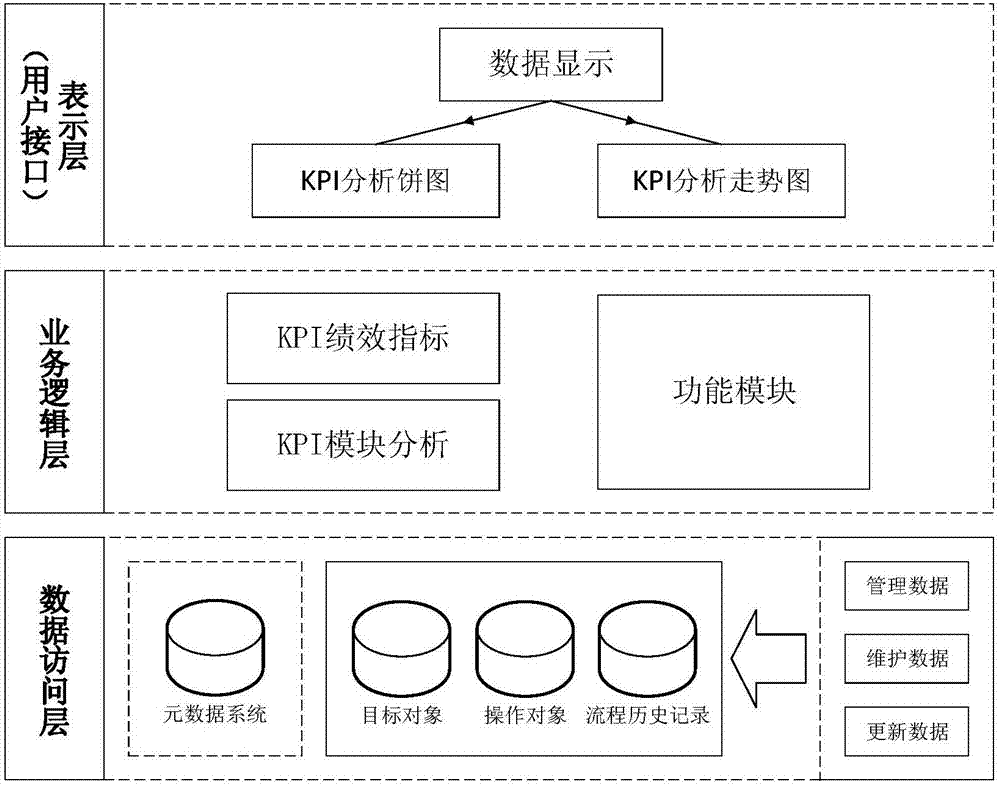

[0020] attached figure 1 It is the architecture diagram of the quality assessment system, such as figure 1 As shown, the system adopts a three-tier architecture based on B / S mode: presentation layer, business logic layer and data access layer. The presentation layer is the user interface (UI) of the system, which is responsible for the interaction between the user and the entire system; the business logic layer is the core of the entire system, which is used to process the requests made by the presentation layer, and then analyze the requests in detail. access, call the data access layer to obtain the corresponding data, and return to the presentation layer; the data access layer is responsible for database access, and this layer encapsulates all operations on the database. In this system, the presentation layer is used to display KPI analysis pie charts and KPI an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com