Processing method of ready-to-eat jellyfish

A processing method and technology of jellyfish, applied in the field of instant jellyfish processing, can solve problems such as inconvenience, extend the fresh-keeping period, and improve the effect of treating high blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

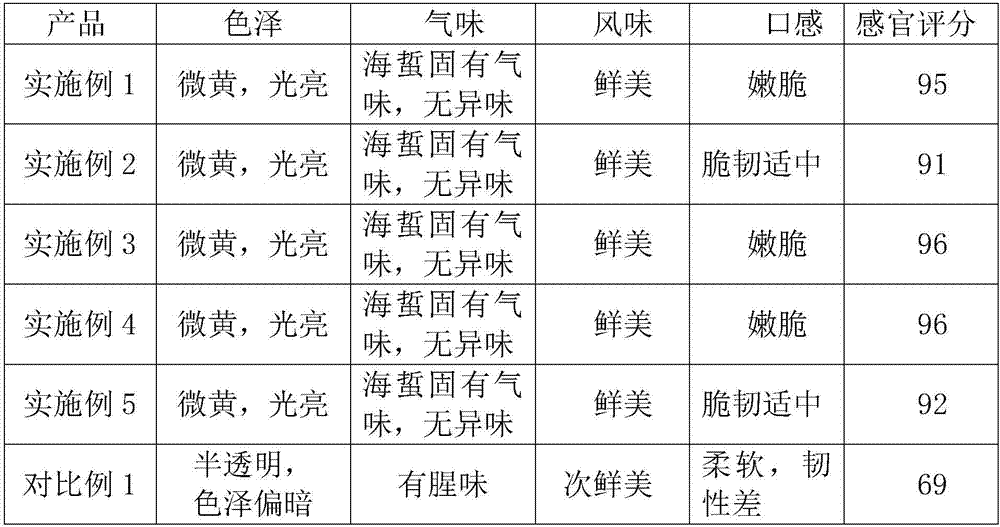

Examples

Embodiment 1

[0050] The processing method of instant jellyfish comprises the following preparation steps:

[0051] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0052] 2) shred: the pretreated fresh jellyfish is automatically shredded with a jellyfish shredder;

[0053] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 4 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 106:10:0.1;

[0054] 4) Dilute: soak in water for 14 hours;

[0055] 5) Dealumination: Soak for 30 minutes with Chinese medicine solution A, rinse;

[0056] 6) Steam scalding: Steam the jellyfish after soaking at 120°C for 15 seconds;

[0057] 7) Cooling: Cool the steamed jellyfish in 6°C water for 100 seconds;

[0058] 8) Pack into bags, inject Chinese medicinal liquid B according to the weight ra...

Embodiment 2

[0071] The processing method of instant jellyfish comprises the following preparation steps:

[0072] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0073] 2) shred: the pretreated fresh jellyfish is automatically shredded with a jellyfish shredder;

[0074] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 6 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 103:12:0.1;

[0075] 4) Dilute: soak in water for 11 hours;

[0076] 5) Dealumination: soak for 40 minutes with Chinese medicine solution A, rinse;

[0077] 6) Steam scalding: Steam the jellyfish after soaking at 115°C for 25 seconds;

[0078] 7) Cooling: Cool the steamed jellyfish in 3°C water for 125 seconds;

[0079] 8) Pack into bags, inject Chinese medicinal liquid B according to the weight ...

Embodiment 3

[0092] The processing method of instant jellyfish comprises the following preparation steps:

[0093] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0094] 2) shred: the pretreated fresh jellyfish is automatically shredded with a jellyfish shredder;

[0095] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 8 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 100:14:0.1;

[0096] 4) Dilute: soak in water for 8 hours;

[0097] 5) Dealumination: soak for 50 minutes with Chinese medicine solution A, rinse;

[0098] 6) Steam scalding: steam the jellyfish after soaking at 110°C for 30s;

[0099] 7) Cooling: Cool the steamed jellyfish in 1°C water for 150 seconds;

[0100] 8) Pack into bags, inject Chinese medicinal liquid B according to the weight ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com