Base station component for individualized implant

An implant and abutment technology, applied in dental implants, medical science, dentistry, etc., can solve the problems of poor self-tapping, small taper contact area, patient pain, etc., achieve positioning and anti-rotation safety, and improve connection stability. , the effect of preventing the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

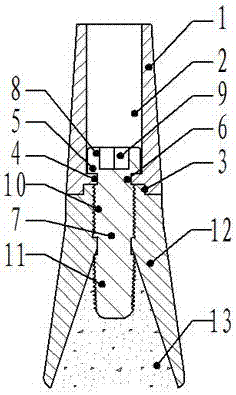

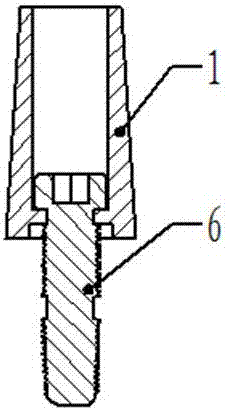

[0037] Such as figure 2 The shown abutment assembly for a personalized implant using subperiosteal implantation includes an abutment main body 1 and a central fixing screw 6 .

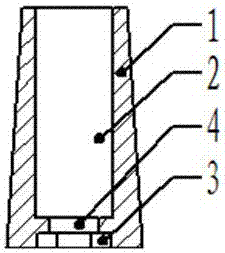

[0038] The main body 1 of the abutment is made of pure titanium material through mechanical processing, and the structure is as follows image 3 As shown, the shape is frustum-shaped, with a diameter of 4.5-6 mm, preferably 4.6 mm, and a height of 4-8 mm, preferably 7 mm. The center of the abutment main body 1 is provided with a through hole 2 through which the central fixing screw 2 passes, and the diameter of the through hole 2 is 3-4 mm. The lower end surface of the abutment main body 1 is provided with an inner octagonal counterbore 3 that matches the outer octagonal corrugated column set in the center of the neck platform of the personalized implant 12, the inner octagonal counterbore 3 is 1.0 mm deep, and the length of the opposite side is 2.5 to 3.5 mm. mm, preferably 2.5 mm. A stepped hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com