A device and method for preparing large-scale high-quality aluminum alloy ingots

An aluminum alloy ingot, high-quality technology, applied in the field of metal material processing, can solve the problems of inability to prepare large-scale aluminum alloy ingots, rough and uneven internal structures, poor surface quality of ingots, etc., to achieve fine grains, reduce Homogenization and processing costs, the effect of fast casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

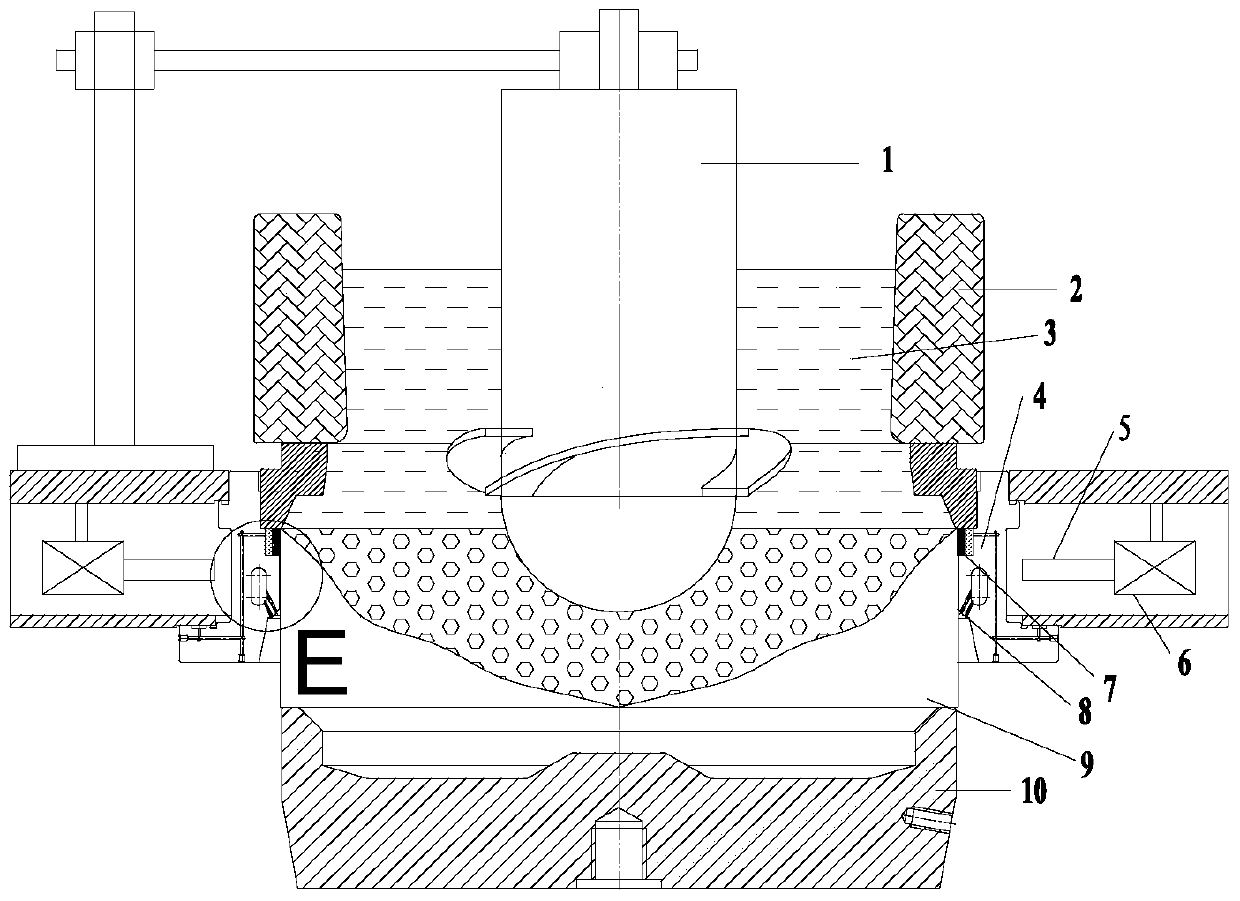

[0045] Adopting the present invention to prepare round ingots of 7075 aluminum alloys with a specification of Φ582 mm requires smooth surfaces and fine and uniform internal structures. The specific implementation is as follows:

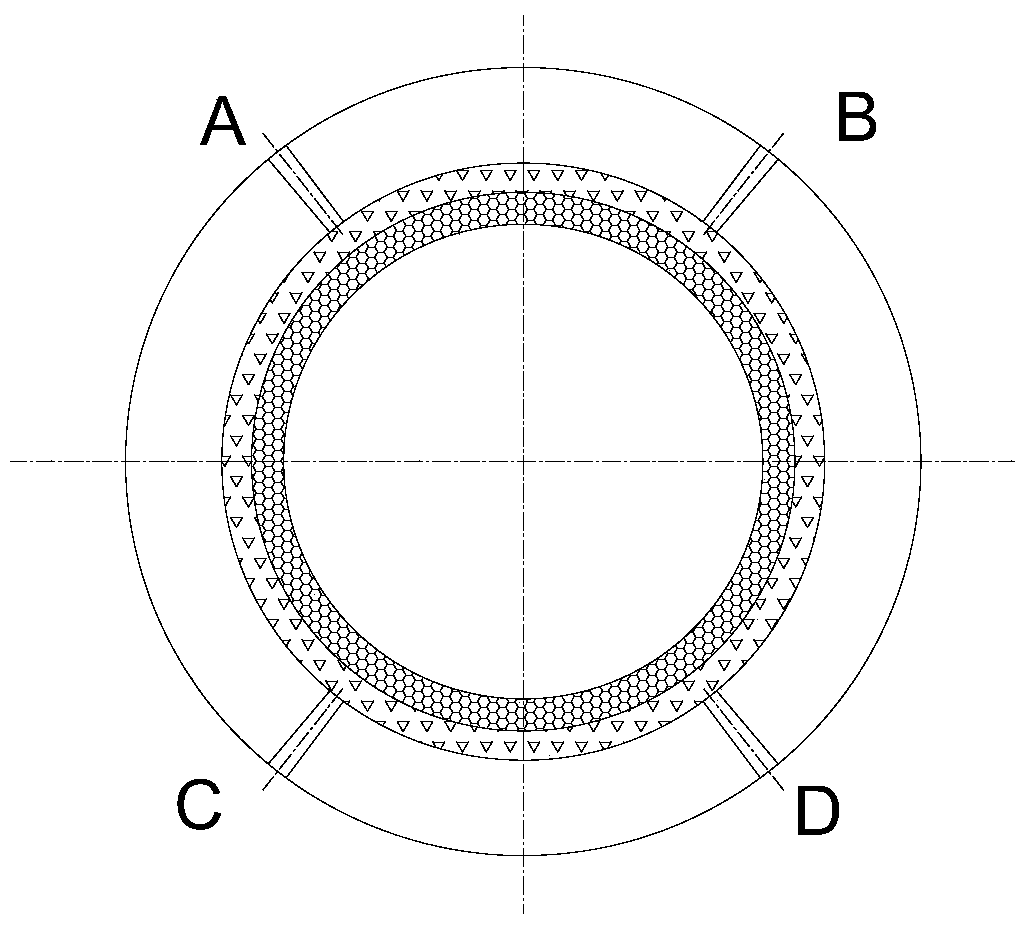

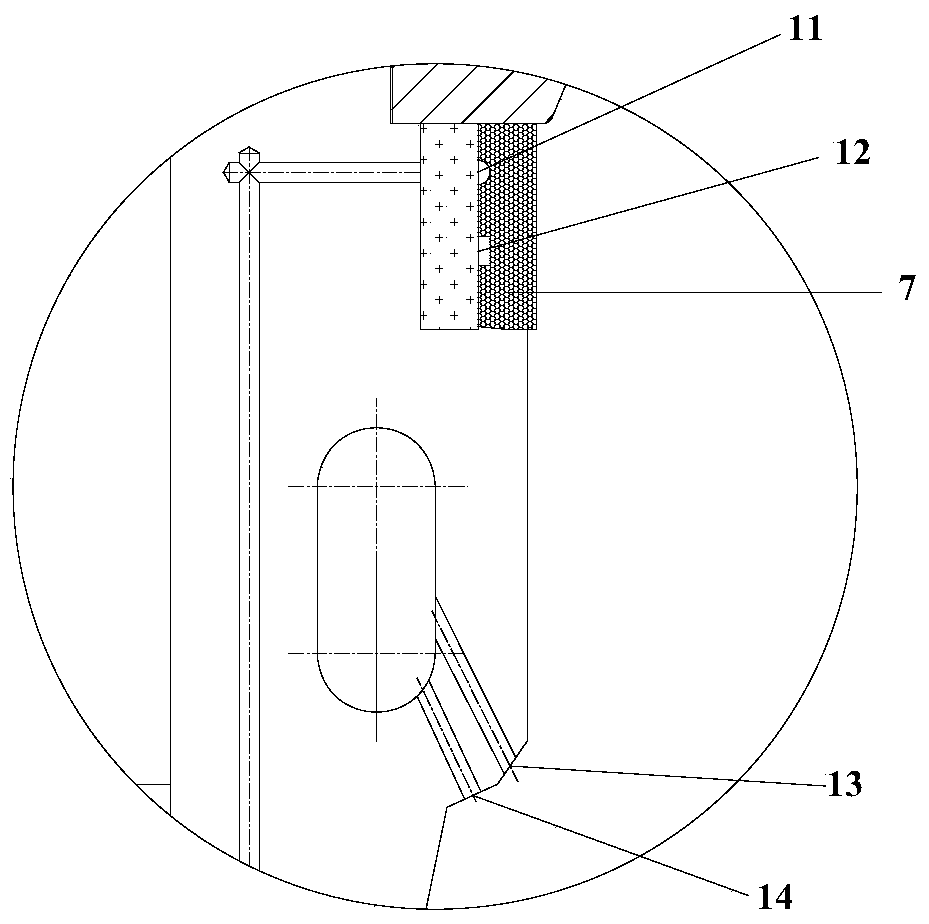

[0046] The schematic diagram of the device structure is as figure 1 As shown, the oil-gas lubricated crystallizer 4 adopts a partitioned air supply system. The graphite ring 7 is provided with an air groove 12 and an oil groove 11. The air groove 12 is divided into 4 sections, and the length of each section of the air groove 12 is 456mm. Channel, separate air supply, separate control; oil tank 11 is separated from air tank 12, oil tank 11 is arranged on the upper part of air tank 12, and graphite ring 7 is made of porous graphite. The angle between the upper row of spray holes 13 and the crystallizer wall is 25°, and the diameter is 2mm. The angle between the bottom row of water spray holes 14 and the crystallizer wall is 10°, and the diameter is 5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com