Production of cellulose/polyacrylonitrile homogeneous mixed solution

A polyacrylonitrile and mixed solution technology, applied in the direction of cellulose/protein conjugated artificial filaments, conjugated synthetic polymer artificial filaments, etc., can solve the complicated process parameters, strong corrosion of inorganic reagents, and endanger operators Health and other issues, to achieve the effect of increasing economic benefits, easy recycling, and avoiding phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

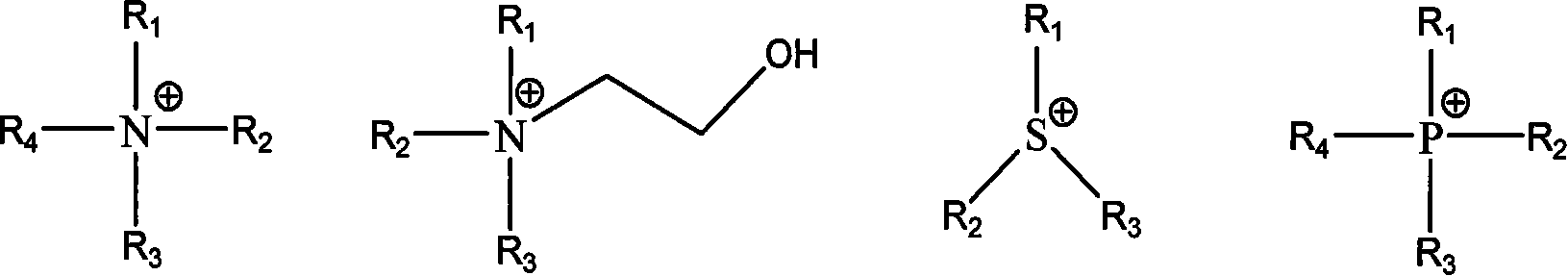

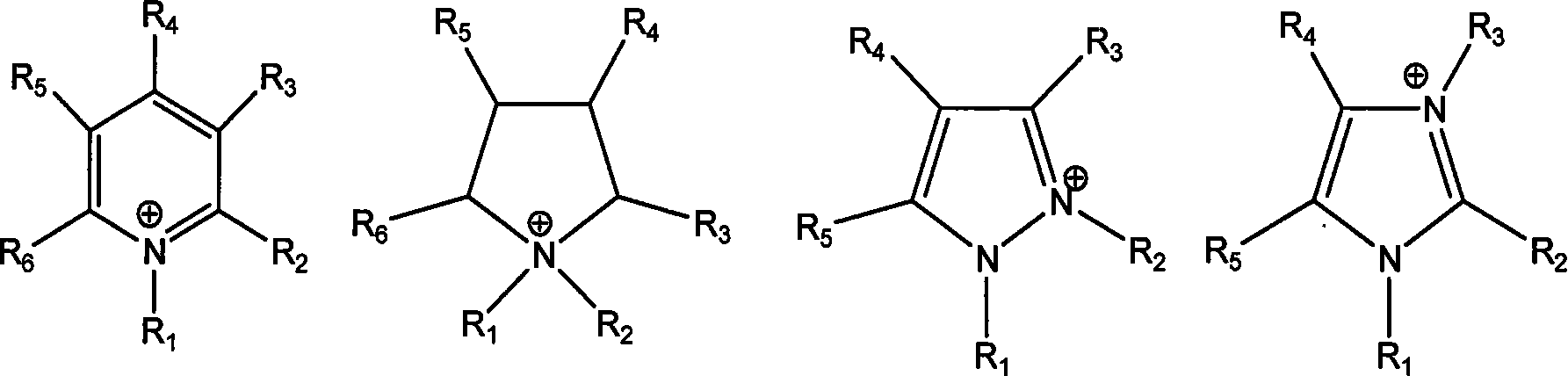

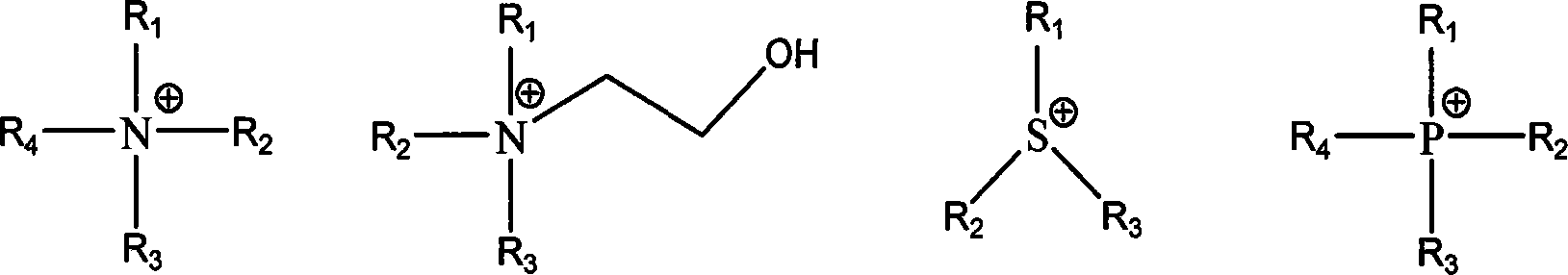

Method used

Image

Examples

Embodiment 1

[0029] Raw material: bamboo pulp, cellulose content 95%, polymerization degree 300;

[0030] Polyacrylonitrile with a viscosity average molecular weight of 5.0×10 4 , is a copolymer comprising a first monomer, a second monomer and a third monomer, wherein the first monomer is 81.8% by mass of acrylonitrile, and the second monomer is 18% by mass of methyl acrylate %, the content of the third monomer itaconic acid is 0.2%;

[0031] Ionic liquid, 1-butyl-3-methylimidazolium chloride.

[0032] Mix 1% dry bamboo pulp with 99% polyacrylonitrile evenly, then add this mixture into 1-butyl-3-methylimidazolium chloride, and dissolve it at 70°C for 2 hours to obtain a stable Uniform solution, the mass percent of 1-butyl-3-methylimidazolium chloride in the solution is 75%. Using water as coagulant, cellulose / polyacrylonitrile blend composite film or composite fiber can be prepared.

Embodiment 2

[0034] Raw material: wood pulp, cellulose content 96%, polymerization degree 500;

[0035] Polyacrylonitrile, viscosity average molecular weight 2.0×10 5 , is a copolymer comprising a first monomer and a second monomer, wherein the content of the first monomer is acrylonitrile is 90%, and the content of the second monomer methyl methacrylate is 10%.

[0036] Ionic liquid, 1-allyl-3-methylimidazolium chloride.

[0037] Mix 30% wood pulp with 70% polyacrylonitrile evenly, add this mixture to 1-allyl-3-methylimidazolium chloride and mix, swell at 45°C for 45min, dehydrate, and then Dissolve at 120°C for 1 hour to obtain a stable and uniform solution, the content of 1-allyl-3-methylimidazolium chloride in the solution is 90%. Using water as coagulant, cellulose / polyacrylonitrile blend composite film or composite fiber can be prepared.

Embodiment 3

[0039] Raw materials: cotton pulp, cellulose content 99%, polymerization degree 700; polyacrylonitrile, viscosity average molecular weight 2.0×10 4 , for acrylonitrile homopolymer.

[0040] Ionic liquid, 1-butyl-2-methylpyrazole bromide.

[0041]Add 10% dry cotton pulp into 1-butyl-2-methylpyrazole bromide, stir evenly, dissolve at 90°C for 1 hour to obtain solution ①, add 2% dry poly Add acrylonitrile to 1-butyl-2-methylpyrazole bromide, stir evenly, dissolve at 100°C for 1 hour to obtain solution ②, then mix the same amount of solution ①②, and stir at 100°C for 10 minutes to obtain a stable solution A homogeneous solution, the mass percent of 1-butyl-2-methylpyrazole bromide in the solution is 94%. Using water as coagulant, cellulose / polyacrylonitrile blend composite film or composite fiber can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com