Styrene water-soluble synergic polymerization inhibitor and preparation method thereof

A polymerization inhibitor and water-soluble technology, applied in the field of styrene water-soluble synergistic polymerization inhibitor and its preparation, can solve the problem of poor compatibility between the polymerization inhibitor and styrene, affecting the quality of styrene products, and poor compatibility of the polymerization inhibitor. and other problems, to achieve the effect of promoting mixing and mutual solubility, preventing fouling, and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

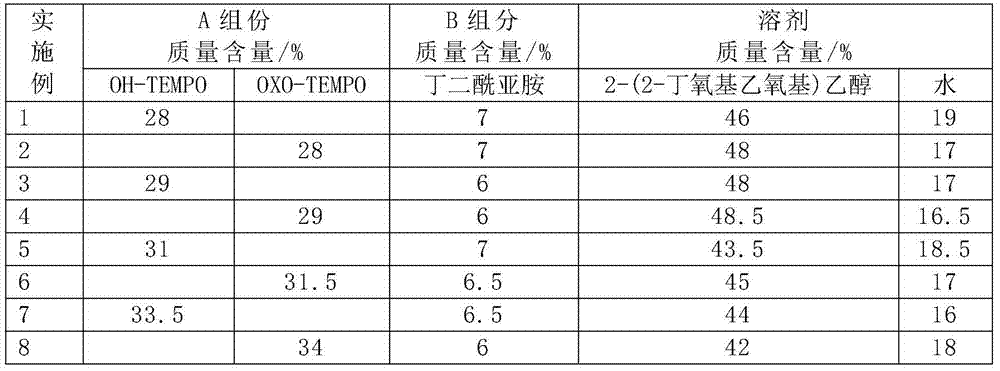

[0029] According to the components and dosage shown in Table 1, use 2-(2-butoxyethoxy)ethanol and water to configure 2-(2-butoxyethoxy)ethanol solution as a solvent, use component A and group Part B configures the main body of the polymerization inhibitor, add the prepared solvent to the prepared main body of the polymerization inhibitor dropwise, and stir evenly at 30-35°C to obtain a clear and transparent liquid that is a styrene water-soluble synergistic polymerization inhibitor.

Embodiment 2-8

[0031] The components and dosage are shown in Table 1, and the configuration steps are the same as in Example 1.

[0032] Table 1

[0033]

Embodiment 9~24

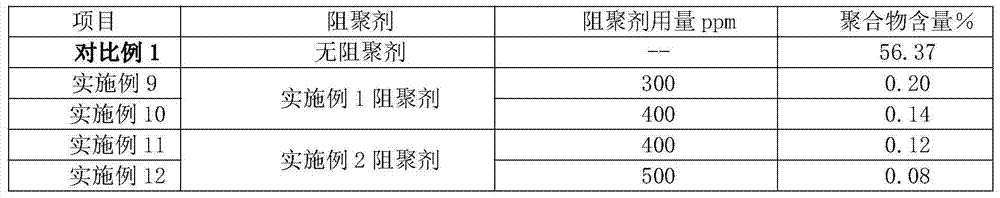

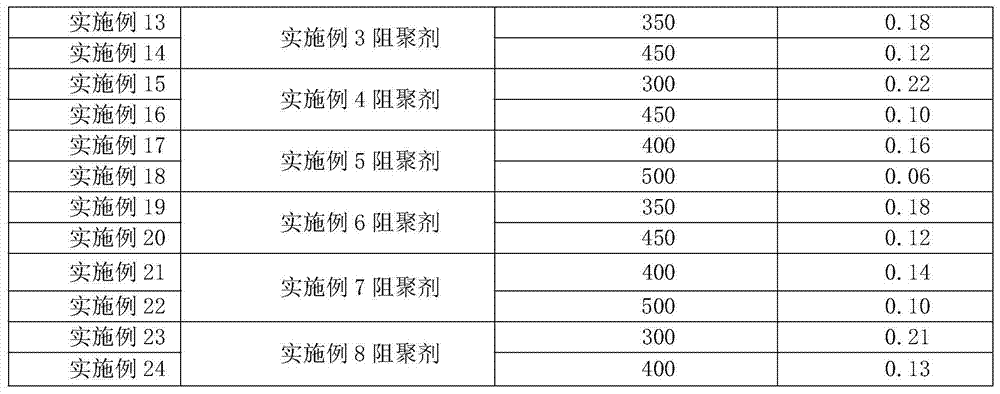

[0035]The styrene water-soluble synergistic polymerization inhibitor that embodiment 1-8 makes is added respectively in styrene according to the dosage shown in table 2, after mixing evenly, inject rectification column bottom through metering pump, in vacuum degree 40~42 kilopascals , Rectification under the condition of rectification tank bottom temperature 118~120℃. Styrene is continuously extracted from the top of the rectification tower, and refluxed to the feed port in the middle of the rectification tower for circular rectification. Under these conditions, the reaction was stable for 4 hours, and the content of styrene polymer in the rectification kettle was measured, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com