Polyacrylamide-containing expansion material composition, self-suspending proppant, and application and preparation method of self-suspending proppant

A technology of polyacrylamide and swelling materials, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and production, and can solve problems such as difficulties in fracturing fluid transportation, polymer compounds blocking oil outlet pores, formation pollution, etc. , to achieve the effect of reducing viscosity, reducing difficulty of transportation, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides the preparation method of above-mentioned self-suspending proppant, and this method comprises the following steps:

[0029] (1) Disperse and mix the proppant body, binder and curing agent uniformly at the first temperature to obtain granular aggregate with binder and / or curing agent attached, wherein, relative to 100 parts by weight of proppant agent body, the amount of the binder is 0.6-12 parts by weight, and the amount of the curing agent is 0.006-1.2 parts by weight;

[0030] (2) Dispersing and mixing the granular aggregate and the expansive material composition at a second temperature so that the expansive material composition is coated on the granular aggregate to obtain a granular self-suspending proppant , wherein, relative to 100 parts by weight of the proppant body, the amount of the expansion material composition is 0.6-12 parts by weight.

[0031] The preparation method of the self-suspending proppant of the present inven...

Embodiment 1

[0038] This example is used to illustrate the expansion material composition of the present invention and the preparation method and self-suspension proppant prepared from the expansion material composition.

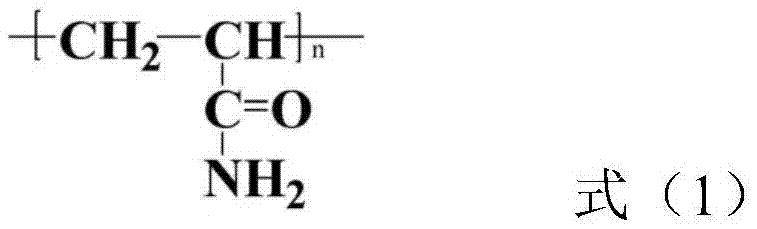

[0039] The expansion material composition of this embodiment is 100 parts by weight of polyacrylamide (weight average molecular weight: 3 million) and 1 part by weight of gum arabic (Tai'an Dingli Rubber Industry Co., Ltd., DL-80).

[0040] (1) Using quartz sand (6-10 mesh in particle size) as raw material, after scrubbing and drying at 120°C for 5 hours, screen 6-40 mesh quartz sand as aggregate;

[0041] (2) Take 100 parts by weight of screened quartz sand, heat it to 240°C, add 0.6 parts by weight of epoxy resin E-51 (618), 0.006 parts by weight of curing agent phthalic anhydride, stir and mix evenly to obtain a binder package Covered granular aggregate;

[0042] (3) When the temperature of the above-mentioned binder-coated granular aggregate drops to 180° C., add 0....

Embodiment 2

[0045] This example is used to illustrate the expansion material composition of the present invention and the preparation method and self-suspension proppant prepared from the expansion material composition.

[0046] The expansion material composition of this embodiment is 100 parts by weight of polyacrylamide (weight average molecular weight: 20 million) and 15 parts by weight of locust bean gum (Jining Huakai Resin Co., Ltd.).

[0047] (1) Take 100 parts by weight of ceramsite (particle size is 100-200 mesh), heat to 190°C, add 12 parts by weight of binder bisphenol A type unsaturated polyester 3301, add curing agent phthalic anhydride 0.9 parts by weight, stirred and mixed evenly to obtain binder-coated granular aggregate;

[0048] (2) When the temperature of the above-mentioned binder-coated granular aggregate drops to 80° C., add 12 parts by weight of the above-mentioned expansion material composition, and stir and mix evenly.

[0049] (3) cooling, crushing, and sieving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com