Manufacture method for paper-based gate-pouring pipes

A technology of paper tube and forming method, which is applied in the direction of textiles and papermaking, can solve the problems of high cost, cumbersomeness, and obstacles to the popularization and use of paper runner tubes, and achieves enhanced bending strength and local anti-sag ability, and is easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Manufacturing method one of L-shaped paper sprue pipe:

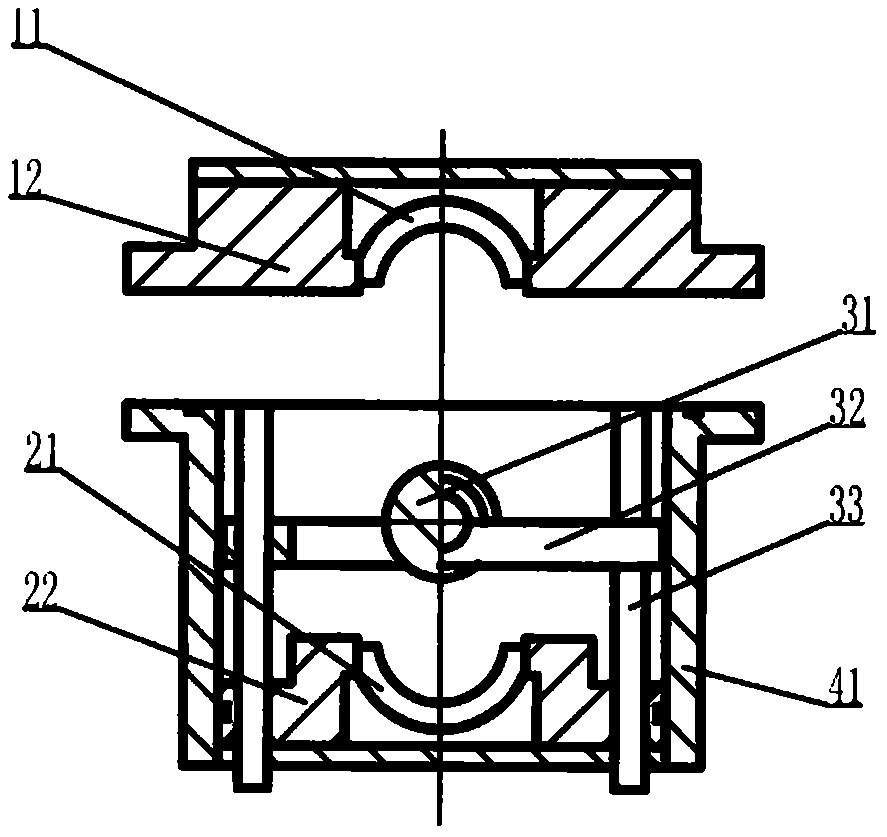

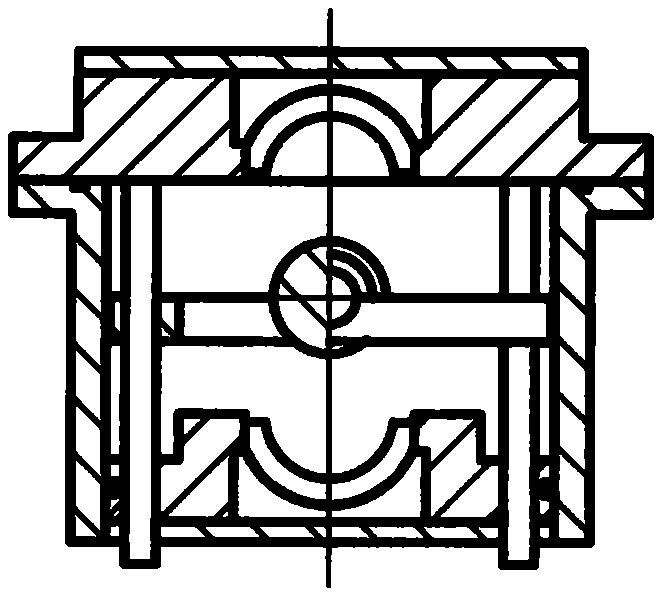

[0026] Step 1: Grouting: Quantitatively inject the slurry with a concentration of 1% prepared from waste newspapers, aluminum silicate powder and ceramic fibers into the cavity of the mold made by sealing extrusion molding, such as figure 1 As shown, the sealed extrusion molding mold consists of an upper half mold 11 and a lower half mold 21 with flanging on the molding surface, an upper half mold mounting plate 12 that can be lifted, and a lower half mold mounting plate fixed on the molding workbench 22. The mandrel 31 made of nylon 6, the mandrel support 32, the mandrel support positioning rod 33 and the circular cylinder 41 which are dynamically and sealingly set on the lower die mounting plate 22, at this time, the upper half-mold mounting plate 12 and the The upper end surface of the cylindrical barrel 41 is separated, and the cavity formed by the cylindrical barrel 41 and the lower mold mountin...

Embodiment 2

[0031] Example 2 Manufacturing method two of L-shaped paper sprue pipe:

[0032] Step 1: Grouting The slurry with a concentration of 1.5% prepared from wood pulp, aluminum silicate ore powder, ceramic fiber and silica sol is quantitatively injected into the cavity of the mold made by sealing extrusion molding, Except for the shape and size of the molding surface (wherein the ratio of the flanging width to the tube diameter of the molding surfaces of the upper half-mold 11 and the lower half-mold 21 is smaller than that of Example 1), the mold composition is the same as that of Example 1.

[0033]Step 2: Forming After the two half-moulds 11 and 21 are closely bonded, the maximum pressure on the fiber layer on the forming surface is greater than 10Mpa and reaches 20Mpa, the rest are the same as in Example 1;

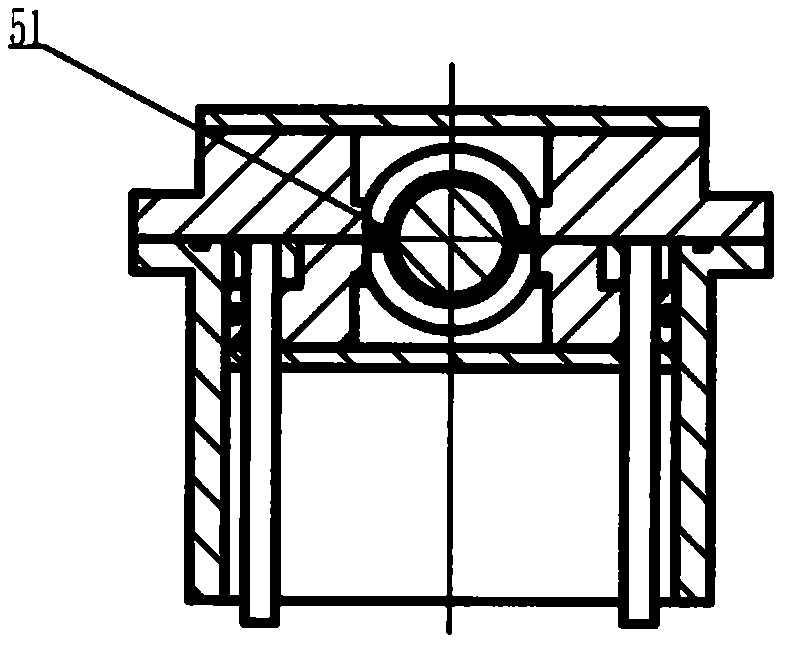

[0034] Step 3: Dry the upper mold mounting plate 12 and open the mold cavity, take out the formed wet blank of the L-shaped paper tube 51 with a moisture content of about ...

Embodiment 3

[0037] Embodiment 3 Manufacturing method five of L-shaped paper sprue pipe:

[0038] Will mix waste and old newspapers, carbon fibers and adhesives by the weight ratio disclosed by Kao technology to prepare the slurry and inject quantitatively into the mold cavity made by the sealed extrusion molding method. The following steps are the same as in Example 1, but can Step 5 of Example 1 is not included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com