A kind of lithography machine motion platform system and lithography machine

A technology of a lithography machine and a motion table, applied in the field of lithography, can solve the problems of poor flatness, high manufacturing difficulty and cost, and easy deformation, so as to reduce manufacturing cost and manufacturing difficulty, facilitate processing and manufacturing, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

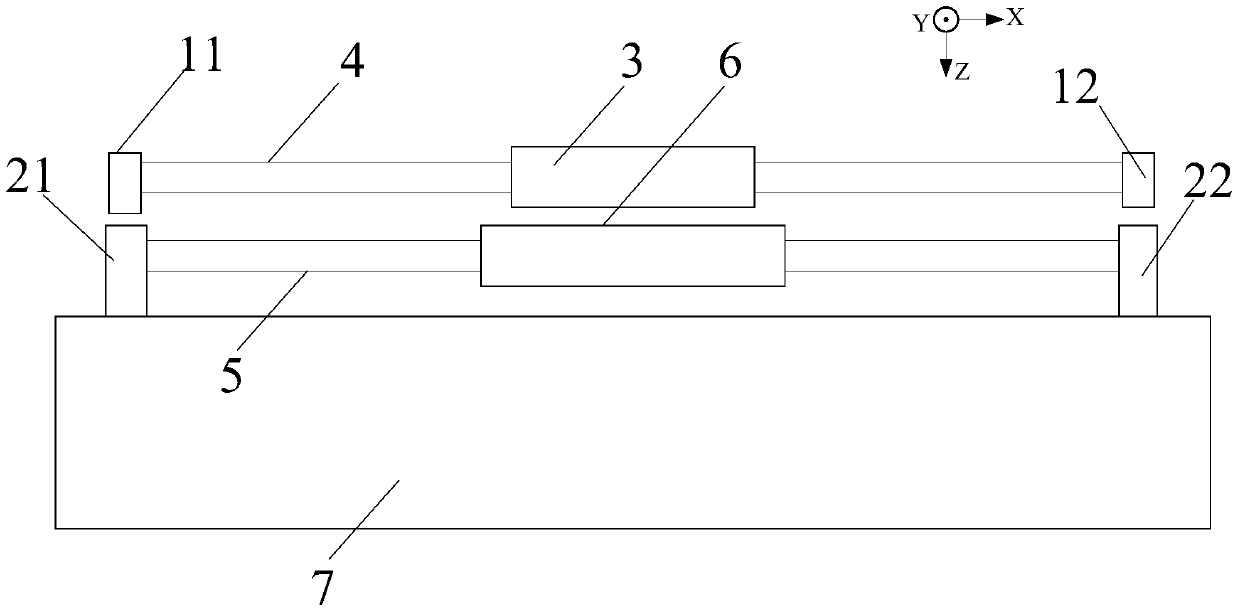

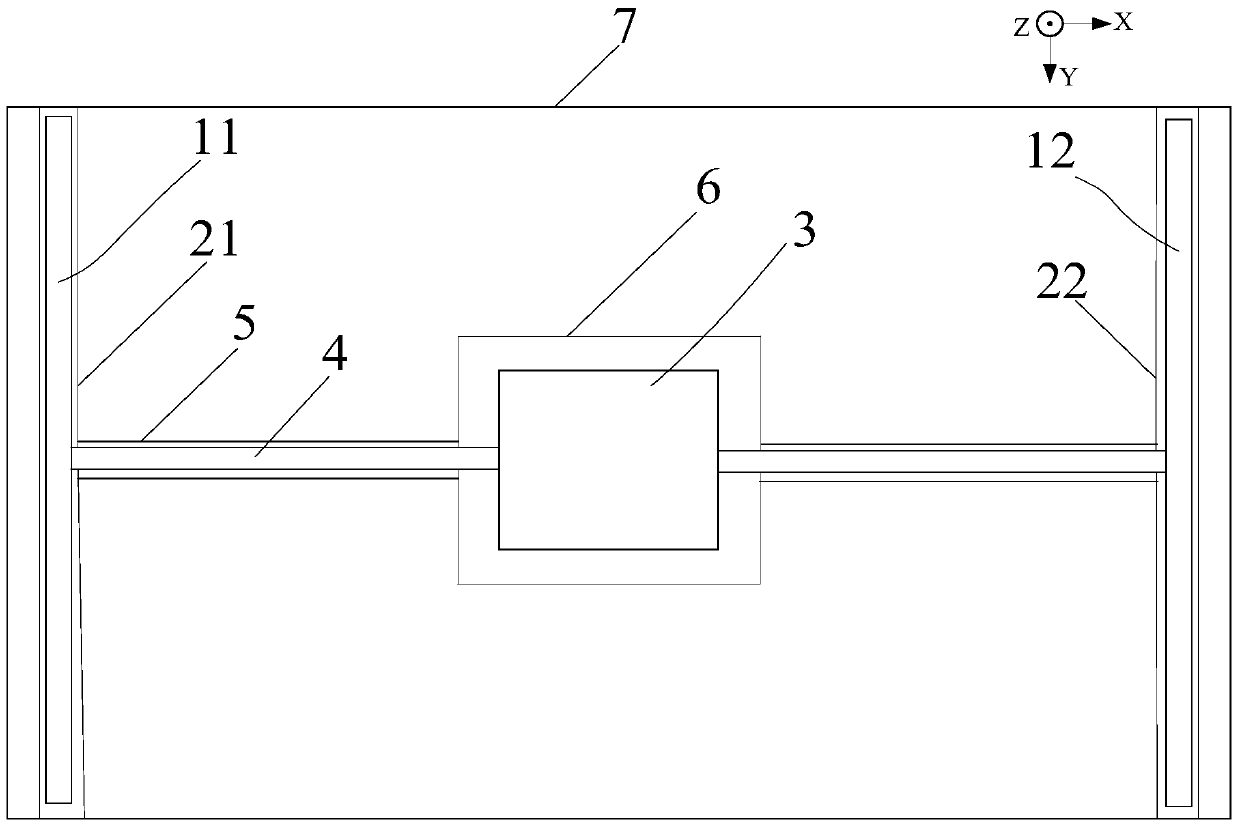

[0031] Such as figure 1 and figure 2 As shown, the lithography machine moving table system of this embodiment includes a base table 7 and a workpiece table 3 located above the base table 7, and also includes a The follow-up table 6 is used for follow-up movement, the lower surface of the workpiece table 3 is air-floated above the follow-up table 6 , and the upper surface of the follow-up table 6 is used as the air-floating support surface of the workpiece table 3 . The workpiece table 3 is driven by a first drive unit, and the follower table 6 is driven by a second drive unit. The first drive unit drives the workpiece table 3 to move two-dimensionally on the plane of the base table 7, and the second drive unit drives the follower table 6 to perform one-dimensional or two-dimensional motion on the plane of the base table 7. sports.

[0032] In the lithography machine moving table system of this embodiment, by adding a follower table 6 that follows the work table 3 between t...

Embodiment 2

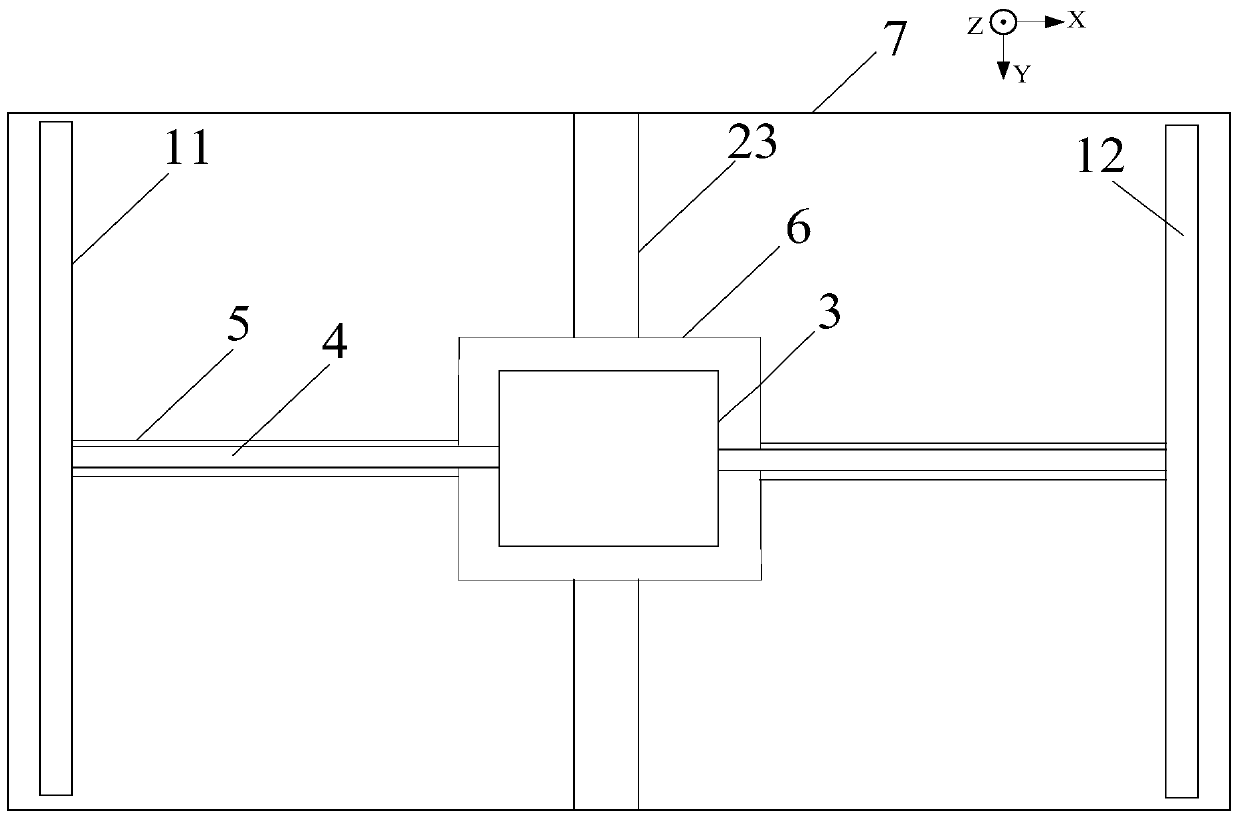

[0047] image 3 Shown is a top view of Embodiment 2 of the lithography machine moving table system of the present invention, which is different from Embodiment 1 in that the number of the Y-direction motor is one, and the fifth Y-direction motor 23 is adopted, located at the base The central position of the platform 7 forms a cross-shaped structure with the second X-direction motor 5 .

[0048] Using the above technology, compared with Embodiment 1, one Y-direction motor is reduced, the structure is simplified, and the cost of the whole system is reduced.

Embodiment 3

[0050] Figure 4 and Figure 5 Shown is a side view and an attached view of Embodiment 3 of the lithography machine moving table system of the present invention, which is different from Embodiments 1 and 2 in that the second drive unit drives the follower table 6 on the base The base 7 performs one-dimensional movement on the plane. If the stroke of the workpiece table 3 in the X-axis is not less than the stroke in the Y-axis, the second drive unit omits the Y-direction motor and uses a third X-direction motor 81 and the fourth X-direction motor 82, the follow-up table 6 is arranged on the movers of the third X-direction motor 81 and the fourth X-direction motor 82, and the width of the follow-up table 6 in the Y axis is greater than or equal to the workpiece table 3 Travel range on the Y axis. The third X-direction motor 81 and the fourth X-direction motor 82 are symmetrically arranged, and are arranged on both sides of the base platform 7 along the X-axis, and are mutually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com