Demagnetizing and verifying apparatus for transformer

A technology for verifying devices and transformers, which is applied in the direction of instruments, magnetic objects, and the size/direction of magnetic fields, and can solve problems such as poor applicability in production sites, and achieve the effects of light weight, convenient operation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

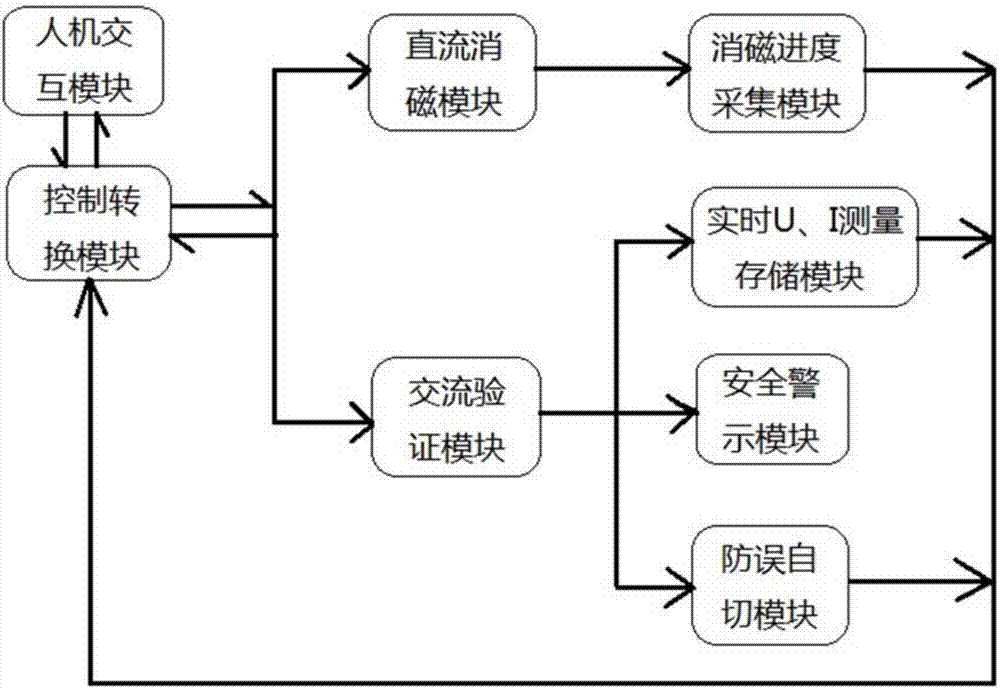

[0029] The working flow chart of the transformer degaussing and verification device is as follows: figure 1 As shown, the transformer degaussing and verification device needs to have the following functions:

[0030] (1) DC degaussing function: limited by the actual operating conditions on site, the device cannot be too heavy and bulky, and the traditional AC degaussing method to eliminate residual magnetism can no longer meet the needs of practical applications. The device developed this time adopts the method of DC degaussing, and can select the gear of the amplitude of the output DC current value during the process of DC degaussing, and display the progress of degaussing during the degaussing process, so as to give the on-site staff a reference on the test time , to prevent blind waiting.

[0031] (2) AC residual magnetism verification function: According to the actual operation status after putting into operation, the power frequency voltage is loaded on the transformer. ...

Embodiment approach

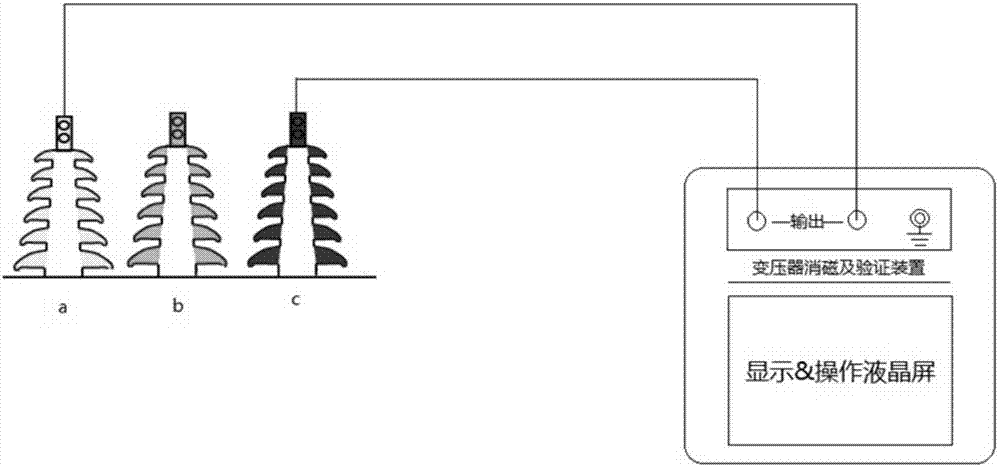

[0044] The wiring of this device is very simple, and the degaussing and verification can be carried out at the low-voltage end of the transformer. Such as figure 2 As shown, according to the practice of testing the DC resistance of large-capacity transformers on site, the DC resistance measurement of the delta-connected low-voltage windings is usually carried out in the order of ab, bc, and ca. The two phases (it is recommended to connect to the pile head of the last two phases tested according to the habit, take ca as an example) are connected to the two terminals of the device, and the operation can be carried out according to the operation process on the panel. That is to measure the excitation current of ca before the DC resistance test of the main transformer and automatically record the data by the device, then use the device to demagnetize ca, measure the excitation current of ca again after degaussing, and compare it with the excitation current before the DC resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com