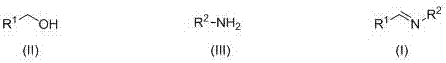

Method for preparing imine compound from alcohol and amine through catalytic oxidation

An amine compound, catalytic oxidation technology, applied in the preparation of imino compounds, sulfide preparation, organic chemistry, etc., can solve the problems of long reaction time, low yield of product imine, limited range of reaction substrates, etc. Environmental costs, avoidance of pollution problems, easy and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

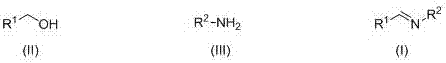

Examples

Embodiment 1

[0027] Example 1: N - Preparation of benzylaniline (Formula 1)

[0028] Add 1 mmol of aniline, 1.2 mmol of benzyl alcohol, 0.03 mmol of ABNO, 0.3 mmol of KOH and 0.5 mL of toluene into a 35 mL sealed tube, replace the air in the tube with oxygen, seal the bottle with a rubber stopper, and insert an oxygen balloon , put the reaction bottle into a preheated oil bath and heat to 80°C, and react for 4h. Then directly carry out column chromatography separation, use the mixed solution of ethyl acetate / triethylamine volume ratio 100:1 as the eluent, collect the eluate containing the target compound, and evaporate the solvent to obtain the product N -benzylaniline, the isolated yield is 90%.

Embodiment 2

[0029] Example 2: N - Preparation of benzylaniline (Formula 1)

[0030] Reaction step is with embodiment 1, and difference is that toluene changes mixed xylene into, N - The isolated yield of benzylaniline was 85%.

Embodiment 3

[0031] Example 3: N - Preparation of benzylaniline (Formula 1)

[0032] Reaction step is with embodiment 1, and difference is that toluene changes chlorobenzene into, N - The isolated yield of benzylaniline was 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com