Phosphorus-free cleaning agent and preparation method thereof

A cleaning agent and additive technology, applied in the field of application of green and environmentally friendly phosphorus-free cleaning agent and its preparation, to achieve good solubility, cleanability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

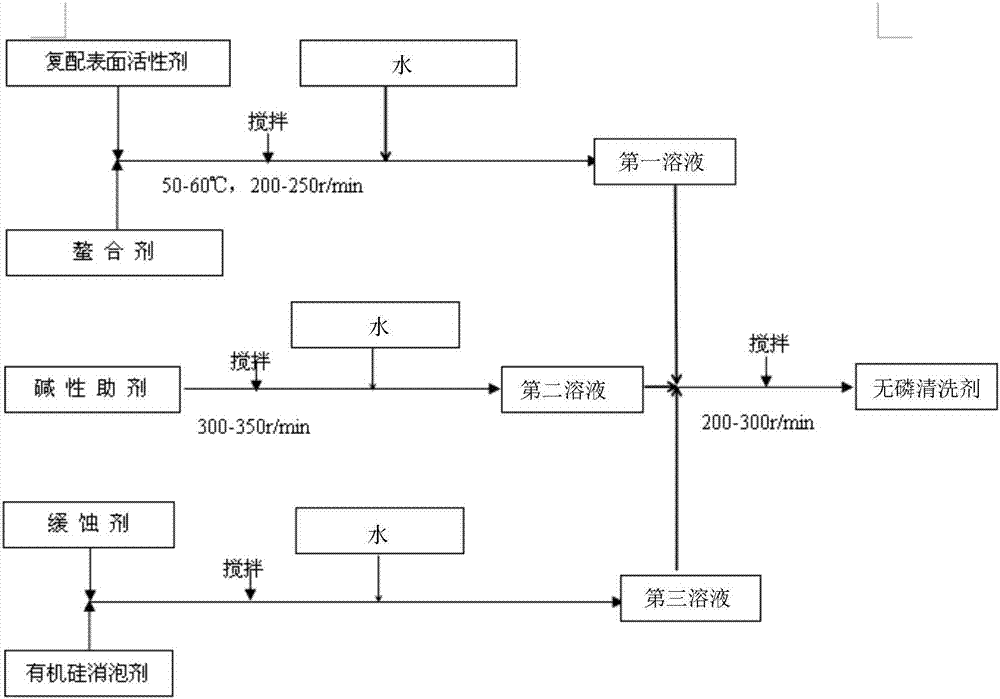

[0025] The preparation method of the phosphorus-free cleaning agent of the present application is to stir the compound surfactant and chelating agent and add water to mix to form the first solution; wherein the stirring temperature is between 50 degrees Celsius and 60 degrees Celsius, and the stirring speed is between 200rpm / min Between and 250 rpm / min, the mixing time was 30 minutes. At the same time, the alkaline additive is stirred and mixed with water to form a second solution; wherein the stirring speed is between 300 rpm / min and 350 rpm / min, and the mixing time is 20 minutes. Stir the corrosion inhibitor and the silicone defoamer at the same time, add water and mix to form a third solution; the mixing time is 30 minutes. Finally, the first solution, the second solution and the third solution are uniformly stirred to form a phosphorus-free cleaning agent; the stirring time is 15 minutes, and the stirring speed is between 200 rpm / min and 300 rpm / min.

[0026] The followin...

Embodiment 1

[0028] The preparation method of the phosphorus-free cleaning agent of the present embodiment is to add 20 parts of compound surfactants and 15 parts of sodium metasilicate to the reactor and stir, wherein the stirring temperature is between 50 degrees Celsius and 60 degrees Celsius, and the stirring speed is Between 200rpm / min and 250rpm / min, after adding water and mixing, after a mixing time of 30 minutes, the first solution was obtained. Simultaneously, 14 parts of 4A-molecular sieves were stirred at a stirring speed between 300 rpm / min and 350 rpm / min, and water was added while stirring, and the second solution was obtained after 20 minutes. Another 5 parts of EP-alcohol-rich nano-alloy corrosion inhibitor and 0.1 part of silicone oil were added while stirring, and water was added while stirring, and the third solution was obtained after 30 minutes. Finally, the first solution, the second solution, and the third solution were stirred uniformly in sequence, and the stirring...

Embodiment 2

[0030] The preparation method of the phosphorus-free cleaning agent of the present embodiment is to add 21 parts of compound surfactants and 16 parts of sodium metasilicate to the reactor and stir, wherein the stirring temperature is between 50 degrees Celsius and 60 degrees Celsius, and the stirring speed is Between 200rpm / min and 250rpm / min, after adding water and mixing, after a mixing time of 30 minutes, the first solution was obtained. At the same time, 12 parts of 4A-molecular sieves were stirred at a stirring speed between 300rpm / min and 350rpm / min, and water was added while stirring, and the second solution was obtained after 20 minutes. Another 6 parts of EP-alcohol-rich nano-alloy corrosion inhibitor and 0.2 part of silicone oil were added while stirring, and water was added while stirring, and the third solution was obtained after 30 minutes. Finally, the first solution, the second solution, and the third solution were stirred uniformly in sequence, and the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com