Construction method of galvanized steel plate waterproof layer at inside of opening type ceramic plate curtain wall

A technology of galvanized steel sheet and construction method, which is applied in the treatment of walls, building materials, and building components, etc., which can solve the problems of poor waterproof and corrosion resistance of coatings, affecting building functions, and large surrounding environmental pollution, etc., and achieves the construction method step Simple, reduce construction complexity and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

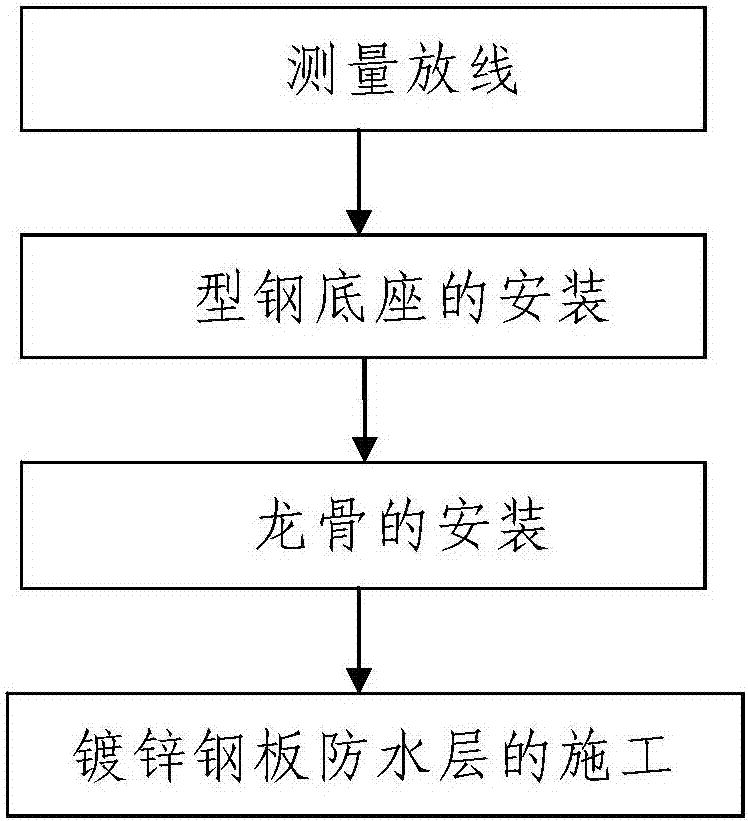

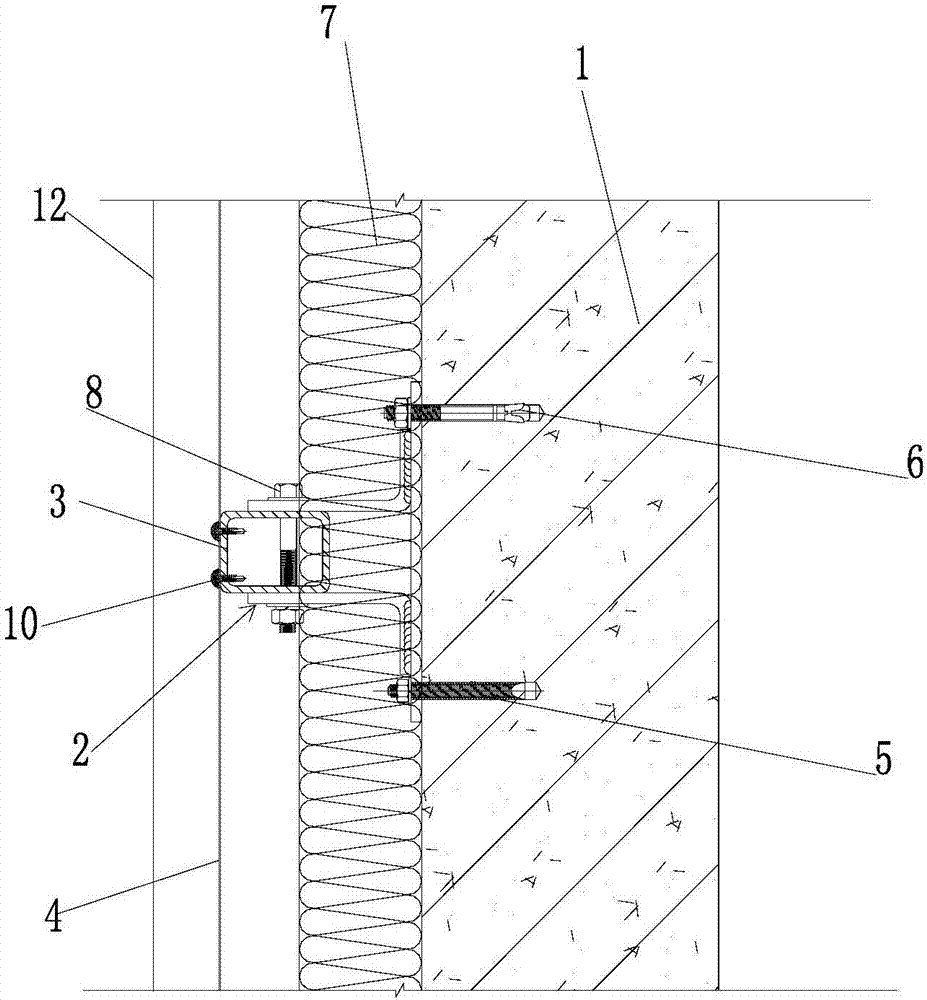

[0042] Such as figure 1 , figure 2 The construction method of the galvanized steel sheet waterproof layer on the inside of the open ceramic panel curtain wall is shown. A waterproof layer is arranged between the inner side of the open ceramic panel curtain wall 12 and the outer side of the thermal insulation layer 7, and the waterproof layer is a galvanized steel sheet waterproof layer 4 , the method includes the following steps:

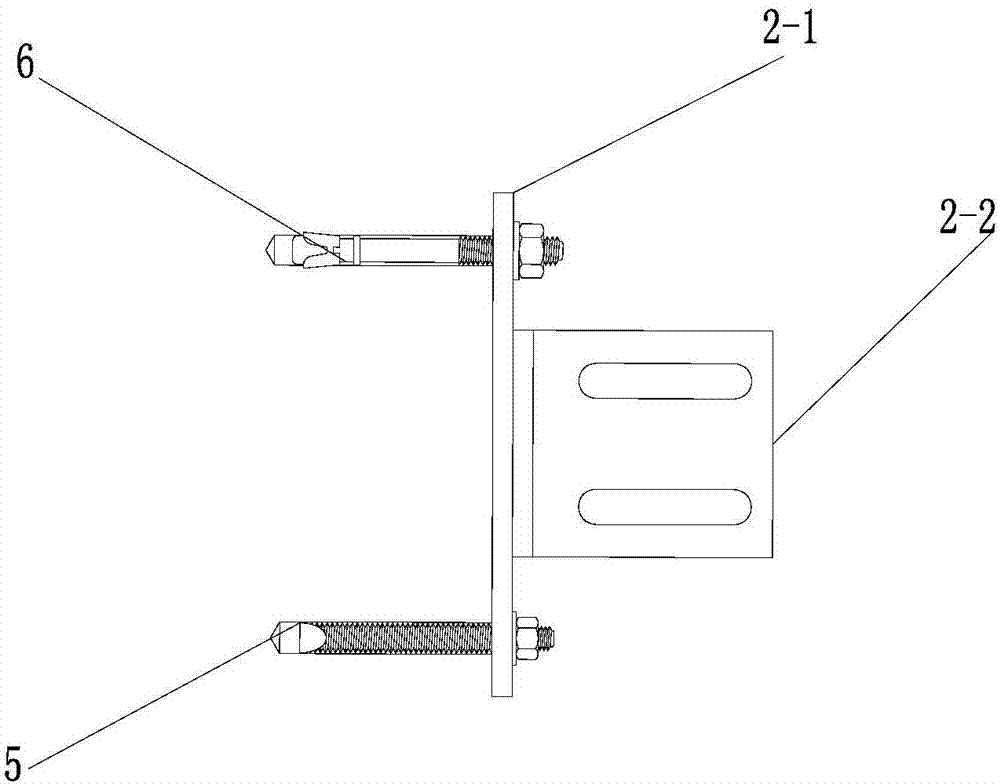

[0043] Step 1. Measure the setting-out line: use the theodolite to control the verticality of the setting-out line, and use the steel wire rope to make the outline control line of the building's outer wall surface 1, and determine it by combining the outline control line of the building's outer wall surface 1 with a manual drawing ruler The position of the steel base 2 and the main keel 3, determine the arrangement of the main keel 3 and the secondary keel 9 according to the design drawing and the construction drawing, and determine the division s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com