Piezoelectric transducer capable of omnidirectionally exciting and receiving horizontal shear wave, and preparation method thereof

A technology of piezoelectric transducers and horizontal shear waves, applied in the generation of ultrasonic/sonic/infrasonic waves, instruments, scientific instruments, etc., which can solve the difficulty of circumferential polarization and uneven omnidirectional performance of piezoelectric transducers , Low energy conversion rate and other issues, to achieve strong practical value, ensure uniformity, and high energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

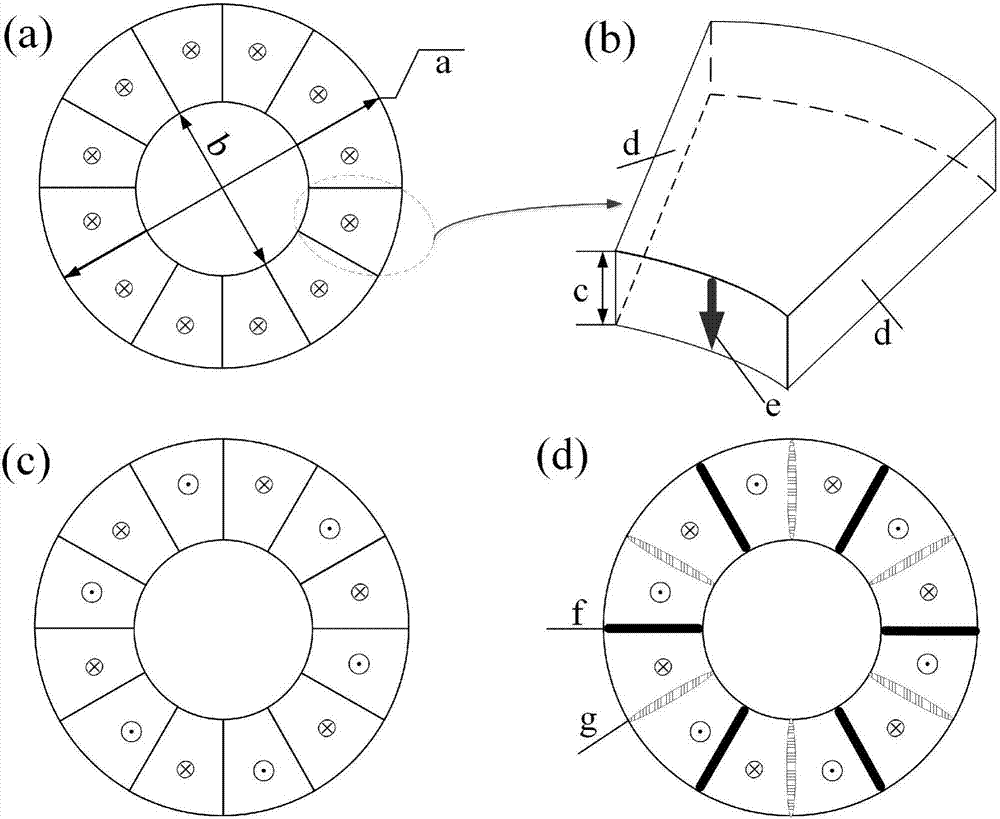

[0029] Such as figure 1 As shown, the preparation method of the omnidirectional excitation and receiving horizontal shear wave piezoelectric transducer of this embodiment includes the following steps:

[0030] 1) Form a piezoelectric ceramic ring with an outer diameter of a, an inner diameter of b, and a thickness of c, respectively form polarized electrodes on the upper and lower surfaces along the thickness direction, and polarize along the direction of thickness c, and grind the polarized electrodes after polarization go, such as figure 1 as shown in (a);

[0031] 2) divide the polarized piezoelectric ceramic ring into 12 sectors on average along the diameter direction, n=6 in this embodiment;

[0032] 3) Use the two sides of each fan-shaped body, that is, the rectangular side d with a size of (a-b)×c, as the electrode surface, and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com