Lithium ion battery and positive electrode piece thereof

A technology for lithium-ion batteries and positive pole pieces, applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as large interface resistance, low adhesion, and active material falling off, and prolong cycle life , reduce interface resistance, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

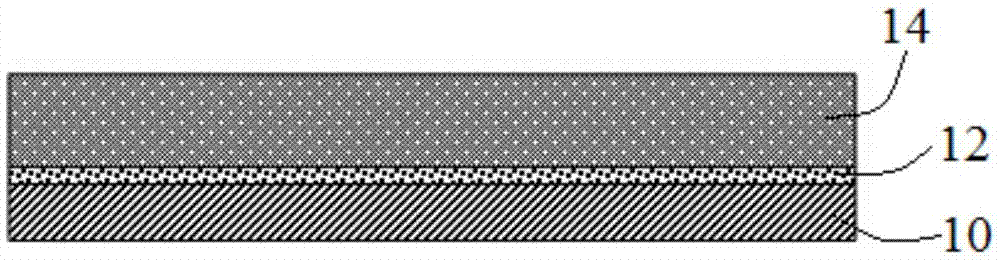

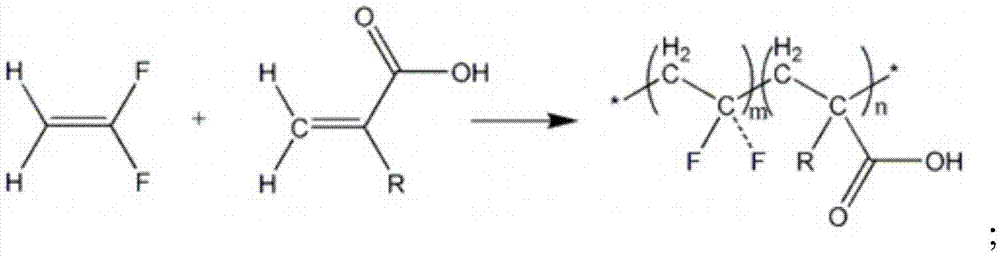

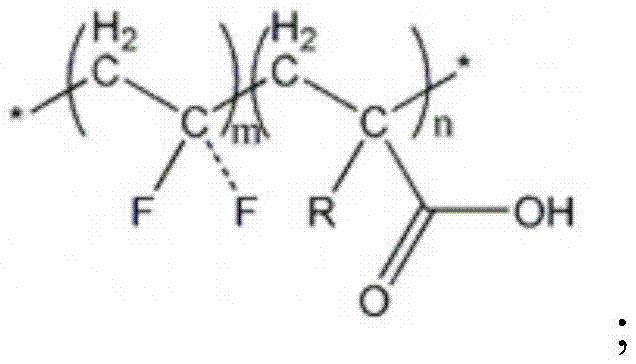

[0029] Mix 30 parts of conductive agent, 70 parts of copolymerized Ac-PVDF (m=0.995, n=0.005) and NMP, stir evenly, and coat on both sides of aluminum foil with a controlled thickness of 1-3 μm, which is the primer layer D1.

[0030] Mix the positive active material NCM (nickel-cobalt lithium manganate ternary material), homopolymerized PVDF, and a conductive agent, and stir at a high speed to obtain a uniformly dispersed mixture containing the positive active material; in the mixture, the solid component contains 95wt% of NCM, 2wt% conductive agent and 3wt% PVDF. Using NMP (N-methylpyrrolidone) as a solvent, the above mixture was made into positive electrode active material slurry, and the solid content in the slurry was 70 wt%. The slurry was evenly coated on both sides of the substrate with the primer layer as above, dried and compacted by a roller press to obtain a positive electrode sheet, which was designated as Z1.

Embodiment 2

[0032] Mix 30 parts of conductive agent, 70 parts of copolymerized Ac-PVDF (m=0.99, n=0.01) and NMP, stir evenly, and coat on both sides of the aluminum foil with a thickness of 1-3 μm, which is the undercoat layer D2.

[0033] Mix positive active material NCM, homopolymerized PVDF, and conductive agent, and stir at high speed to obtain a uniformly dispersed mixture containing positive active material; in the mixture, the solid component contains 95wt% of NCM, 2wt% of conductive agent and 3wt% of PVDF . Using NMP (N-methylpyrrolidone) as a solvent, the above mixture was made into positive electrode active material slurry, and the solid content in the slurry was 70 wt%. The slurry was evenly coated on both sides of the substrate with the primer layer as above, dried and compacted by a roller press to obtain a positive electrode sheet, which was designated as Z2.

Embodiment 3

[0035] Mix 30 parts of conductive agent, 70 parts of copolymerized Ac-PVDF (m=0.97, n=0.03) and NMP, stir evenly, and coat on both sides of the aluminum foil with a controlled thickness of 1-3 μm, which is the primer layer D3.

[0036]Mix positive active material NCM, homopolymerized PVDF, and conductive agent, and stir at high speed to obtain a uniformly dispersed mixture containing positive active material; in the mixture, the solid component contains 95wt% of NCM, 2wt% of conductive agent and 3wt% of PVDF . Using NMP (N-methylpyrrolidone) as a solvent, the above mixture was made into positive electrode active material slurry, and the solid content in the slurry was 70 wt%. The slurry was evenly coated on both sides of the substrate with the undercoat layer above, dried and compacted by a roller press to obtain a positive electrode sheet, which was designated as Z3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com