Bama miniature pig fattening feed and preparation method thereof

The technology of a Bama fragrant pig and its production method, which is applied in the field of animal husbandry, can solve the problems that the Bama fragrant pig has not been balanced in nutrition, the balance of body fluids has not been replenished in time, and the growth and development of the Bama fragrant pig is slow, so as to promote Eating efficiency, improving disease prevention and resistance ability and immune function, improving the effect of gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of fattening feed for Bama pig

[0030] (1) The feed is made by mixing the following raw materials in parts by weight: 60 parts of northeast corn, 20 parts of wheat bran, 10 parts of soybean meal, 0.7 part of stone powder, 0.4 part of calcium hydrogen phosphate, 0.2 part of table salt, 1 part of auxiliary material, 2 parts of Part premix, 1.2 parts plant extract; Wherein,

[0031] The auxiliary material is made by mixing and fermenting egg white, sweet potato stem, tea stem, baicalin, and distiller's yeast according to the mass ratio of 2:2:1:0.5:0.3; the preparation method of the auxiliary material is to mix egg white, sweet potato stem, tea leaf Stem, Scutellaria baicalensis, and koji are mixed and put into a fermenter, 60wt% of the water of the above-mentioned mixture is added, and the temperature is 32°C for 48 hours of fermentation, and the solids taken out are auxiliary materials;

[0032] The premix is made by mixing vitamins, sweeteners, enzyme prepara...

Embodiment 2

[0040] A kind of fattening feed for Bama pig

[0041] (1) The feed is made by mixing the following raw materials in parts by weight: 65 parts of northeast corn, 25 parts of wheat bran, 12 parts of soybean meal, 0.8 part of stone powder, 0.5 part of calcium hydrogen phosphate, 0.4 part of table salt, 1.2 parts of auxiliary materials, 3 parts of Part premix, 1.5 parts plant extract; Wherein,

[0042] The auxiliary material is made by mixing and fermenting egg whites, sweet potato stems, tea stems, baicalin, and distiller's yeast according to the mass ratio of 2:3:2:0.8:0.3; the preparation method of the auxiliary materials is to mix egg whites, sweet potato stems, tea leaves Stem, Scutellaria baicalensis, and koji are mixed and put into a fermenter, adding 65wt% water of the above-mentioned mixture quality, fermenting at a temperature of 34°C for 50 hours, and the solids taken out are auxiliary materials;

[0043] The premix is made by mixing vitamins, sweeteners, enzyme prep...

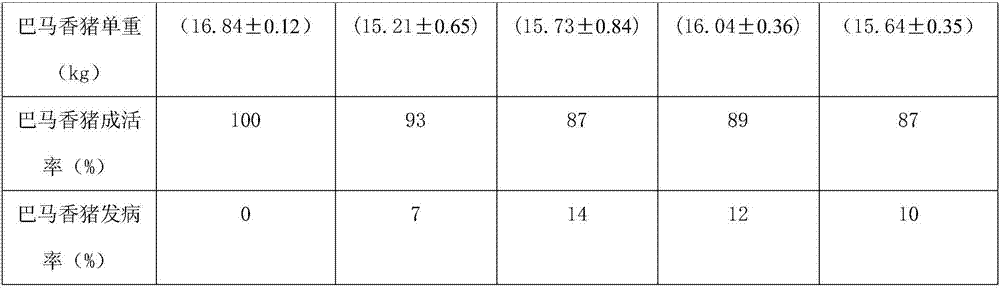

Embodiment 3

[0051] A kind of fattening feed for Bama pig

[0052] (1) The feed is made by mixing the following raw materials in parts by weight: 62 parts of northeast corn, 22 parts of wheat bran, 11 parts of soybean meal, 0.75 part of stone powder, 0.45 part of calcium hydrogen phosphate, 0.3 part of table salt, 1.1 part of auxiliary materials, 2.5 parts of Part premix, 1.4 parts plant extract; Wherein,

[0053] The auxiliary material is made by mixing and fermenting egg whites, sweet potato stems, tea stems, baicalin, and distiller's yeast according to the mass ratio of 2:2.3:1.5:0.6:0.3; the preparation method of the auxiliary materials is to mix egg whites, sweet potato stems, tea leaves Stem, Scutellaria baicalensis, and koji are mixed and put into a fermenter, and 63wt% of the water of the above-mentioned mixture is added, and the temperature is 33°C for 49 hours of fermentation, and the solids taken out are auxiliary materials;

[0054] The premix is made by mixing vitamins, swe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com