Device and method for cyclohexanone rectification

A technology for two towers of cyclohexanone and cyclohexanone, which is applied in the field of rectification devices of cyclohexanone, can solve the problems of increased energy consumption of the rectification system, the quality of product cyclohexanone cannot be stably controlled, and the like, and achieves reduction of steam consumption. and circulating water consumption, high product quality, good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

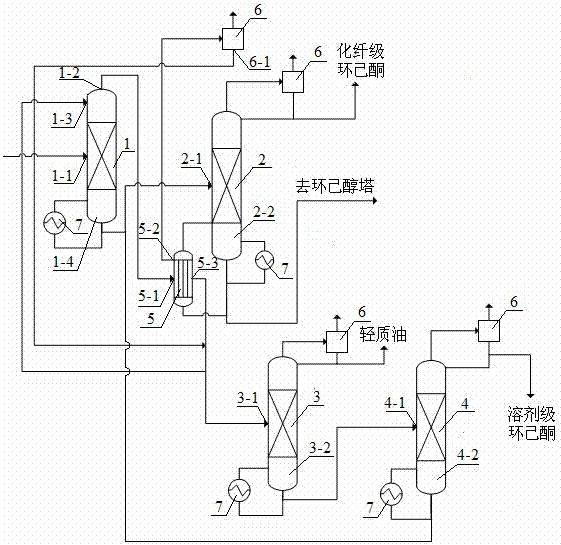

[0045] like figure 1 As shown, the heterogeneous mixture of cyclohexanone / cyclohexanol enters the feed port 1-1 of the first light component tower, and the extracted material from the tower top 1-2 of the light component first tower enters the gas phase inlet 5 of the waste heat reboiler -1, after exchanging heat with the material in the tower kettle 2-2 of the first cyclohexanone tower, it is extracted from the condensate outlet 5-3 of the waste heat reboiler, and the uncondensed gas in the waste heat reboiler 5 is reboiled by waste heat The gas phase outlet 5-2 of the device enters the condenser 6 of the light component-tower 1, and the condensate produced by the condenser outlet 6-1 of the light component-tower 1 is extracted with the waste heat reboiler condensate outlet 5-3 After the condensate of the condensate is combined, enter the reflux port 1-3 of the first light component tower and the feed inlet 3-1 of the second light component tower respectively according to the...

Embodiment 2

[0050] like figure 1 As shown, the heterogeneous mixture of cyclohexanone / cyclohexanol enters the feed port 1-1 of the first light component tower, and the extracted material from the tower top 1-2 of the light component first tower enters the gas phase inlet 5 of the waste heat reboiler -1, after exchanging heat with the material in the tower kettle 2-2 of the first cyclohexanone tower, it is extracted from the condensate outlet 5-3 of the waste heat reboiler, and the uncondensed gas in the waste heat reboiler 5 is reboiled by waste heat The gas phase outlet 5-2 of the device enters the condenser 6 of the light component-tower 1, and the condensate produced by the condenser outlet 6-1 of the light component-tower 1 is extracted with the waste heat reboiler condensate outlet 5-3 After the condensate of the condensate is combined, enter the reflux port 1-3 of the light component first tower and the feed inlet 3-1 of the light component second tower respectively according to the...

Embodiment 3

[0055] like figure 1 As shown, the heterogeneous mixture of cyclohexanone / cyclohexanol enters the feed port 1-1 of the first light component tower, and the extracted material from the tower top 1-2 of the light component first tower enters the gas phase inlet 5 of the waste heat reboiler -1, after exchanging heat with the material in the tower kettle 2-2 of the first cyclohexanone tower, it is extracted from the condensate outlet 5-3 of the waste heat reboiler, and the uncondensed gas in the waste heat reboiler 5 is reboiled by waste heat The gas phase outlet 5-2 of the device enters the condenser 6 of the light component-tower 1, and the condensate produced by the condenser outlet 6-1 of the light component-tower 1 is extracted with the waste heat reboiler condensate outlet 5-3 After the condensate of the condensate is combined, enter the reflux port 1-3 of the light component first tower and the feed inlet 3-1 of the light component second tower respectively according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com