Pulping machine for semi-solid pulping, and semi-solid pulping method

A pulping machine and semi-solid technology, which is applied in the field of semi-solid pulping machines, can solve problems affecting production costs, production efficiency and product quality, affecting production tempo and efficiency, and uneven metal liquid temperature. The effect of uniform phase structure, fast speed, and uniform internal crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

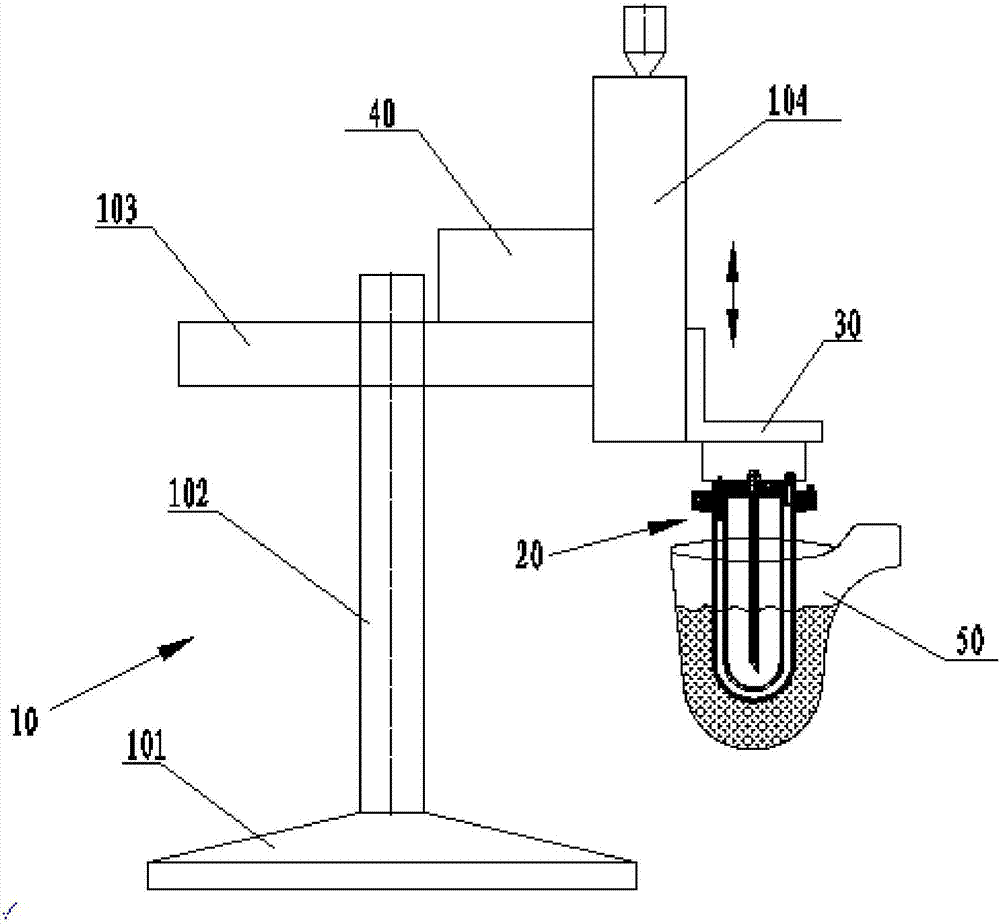

[0046] see figure 1 The shown pulping machine comprises a machine base 10, a support 30 located on the support 10, a pulping head 20 installed on the support 30, and when the soup container 50 is filled with a semi-solid slurry, the system The bottom of the slurry head 20 is inserted into the soup container 50 for slurrying.

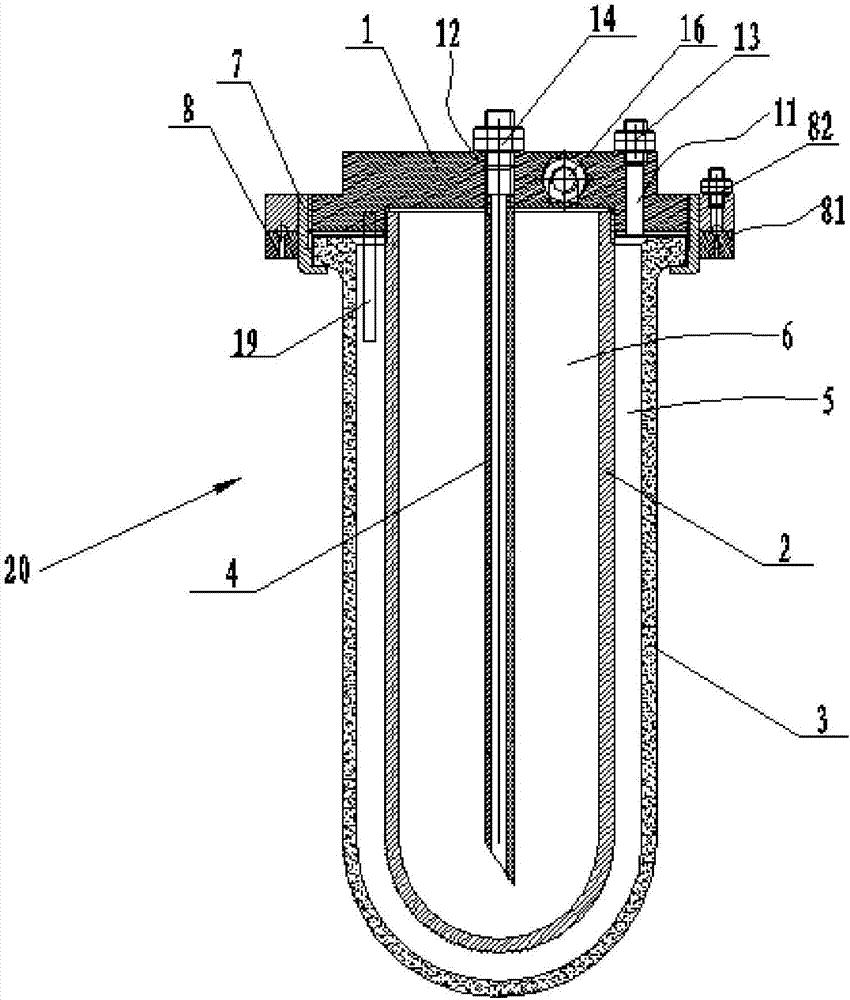

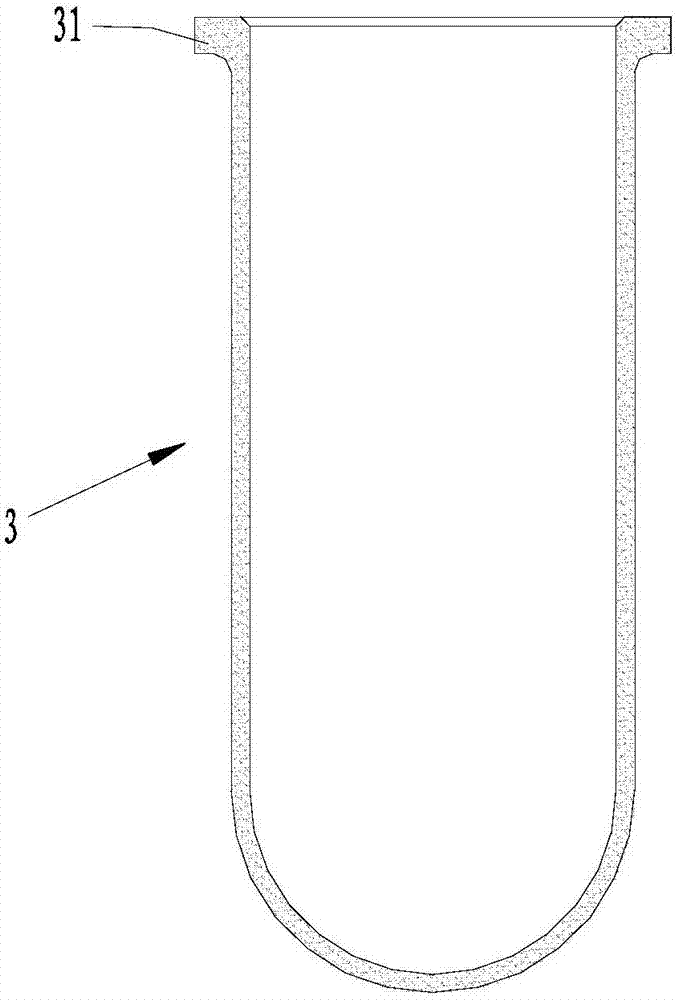

[0047] see figure 2 It is the pulping head 20 used in this embodiment. The pulping head 20 includes a heat exchange inner tank 2, an outer tank 3 sleeved on the outside of the heat exchange inner tank 2, and is fixedly connected to the top of the heat exchange inner tank 2 and the outer tank. 3 the coupling seat 1 on the top, which is fixedly installed on the bracket 30. A closed environment cavity 5 is formed between the heat exchange inner tank 2 , the outer tank 3 and the connection seat 1 , and a closed heat exchange cavity 6 is formed between the heat exchange inner tank 2 and the connection seat 1 .

[0048] Specifically, see figure 2 , Fig...

Embodiment 2

[0079] see Figure 5 The pulper shown with the Figure 6 The pulping head shown is basically consistent with the design concept of embodiment 1, and mainly has the following differences in structure:

[0080] see Figure 5 As shown, the base 10 of the pulping machine includes a base 101, a column 102 erected upwards from the base 101, a beam 103 installed on the top of the column 102 and extending in the horizontal direction through an adjustment seat 105, and the end of the beam 103 is also A support 104 is fixedly provided, and the support 30 is arranged on the support 104 up and down, and the pulping head 20 is fixedly installed on the support 30 .

[0081]Wherein, the column 102 includes a lower column 102a and an upper column 102b that can be slid relative to each other along the vertical direction to realize height adjustment. The seat 105 is connected, the beam 103 is provided with a first handwheel 106 for adjusting the horizontal position of the beam 103 relative t...

Embodiment 3

[0086] see Figure 7 The structure of the machine base 10 of the shown pulping machine is the same as the structure of the machine base 10 in the pulping machine of Embodiment 2, and will not be repeated here. The main difference between it and Embodiment 2 is that the coupling seat 1 on the pulping head 20 is rotatably connected to the support 30 through a rotating shaft (not shown in the figure) extending vertically through the axis line, and the support 30 A rotary motor 60 for driving the coupling base 1 to rotate around the axis of the above-mentioned rotating shaft is also provided.

[0087] see Figure 8 , Figure 9 As shown, in this embodiment, on the pulping head 20, a stirring impeller 9 is fixedly set on the lower body of the outer bladder 3, and the stirring impeller 9 has a plurality of blades distributed evenly along the circumferential direction, so as to Agitation of the slurry is formed during the pulping process.

[0088] In this way, in the pulping machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com