Method for connecting mobile phone sapphire screen with metal bounding frame

A connection method, sapphire technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as deformation, and achieve the effects of high efficiency, short time and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of connection method of mobile phone sapphire screen and metal enclosure is carried out according to the following steps among the present invention:

[0022] Step a, the surface of the sapphire screen and the titanium alloy frame to be electroless plated are respectively polished with 180# sandpaper, and then ultrasonically cleaned with acetone at room temperature for 10 minutes;

[0023] Step b. Cover the remaining part of the exposed sapphire screen to be connected after the treatment in step 1, and use electroless plating to first plate a layer of metal nickel, and then plate a layer of SnAgCu;

[0024] Step c, expose the titanium alloy metal frame to cover the remaining part of the connecting surface, first plate a layer of metal nickel by electroless plating, and then plate a layer of SnAgCu;

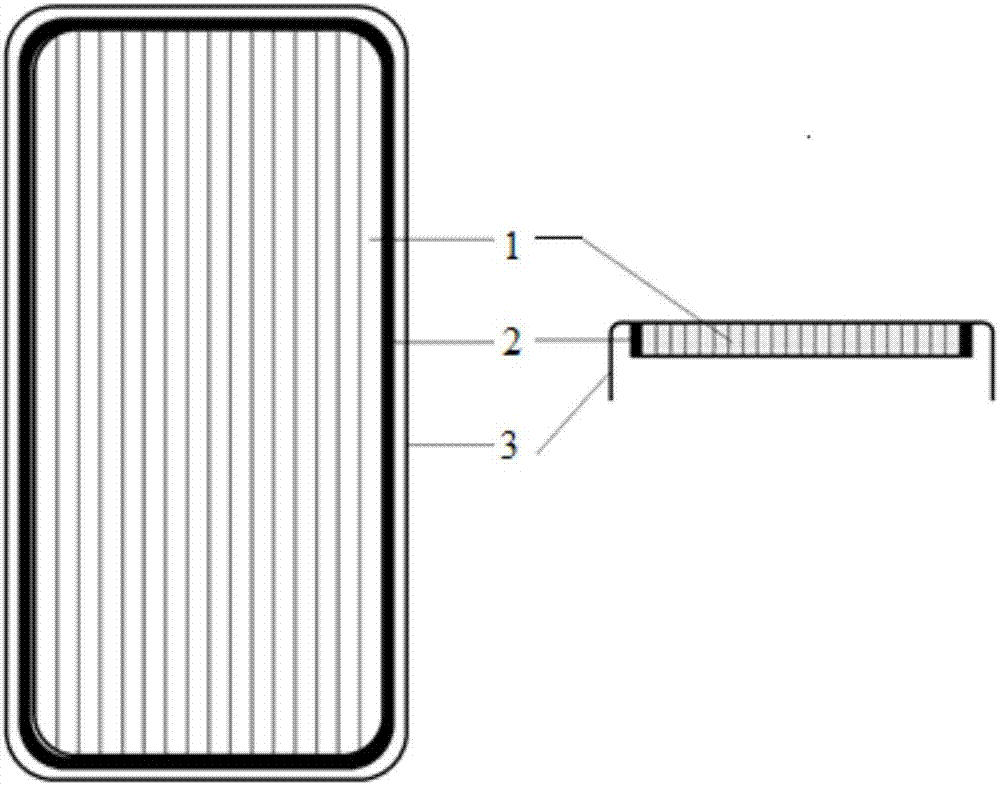

[0025] Step d, place the sapphire screen to be connected and the titanium alloy frame to be connected, and fix it with the fixture (see figure 1 ), and then use a 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com