Synthesis technology of trimethyl orthoformate

A technology of trimethyl orthoformate and a synthesis process, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry and other directions, can solve the problems of high safety requirements, the need for refrigeration devices and the like, and achieves low cost and processing reaction. mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

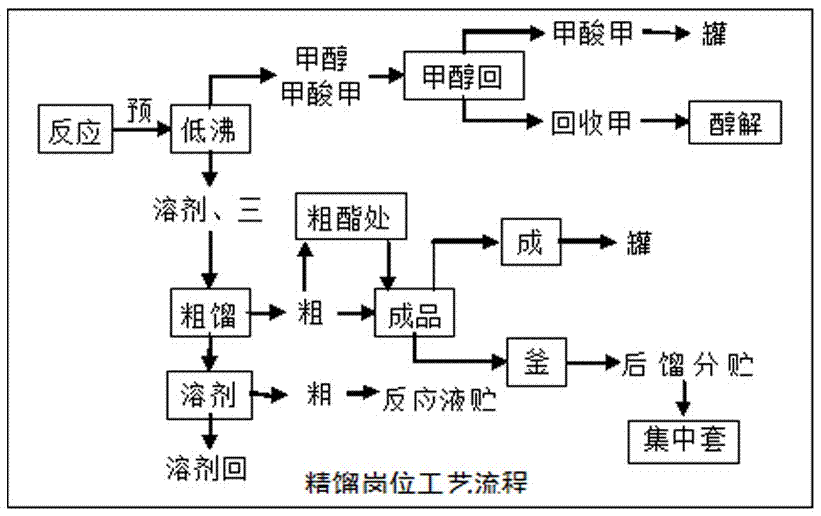

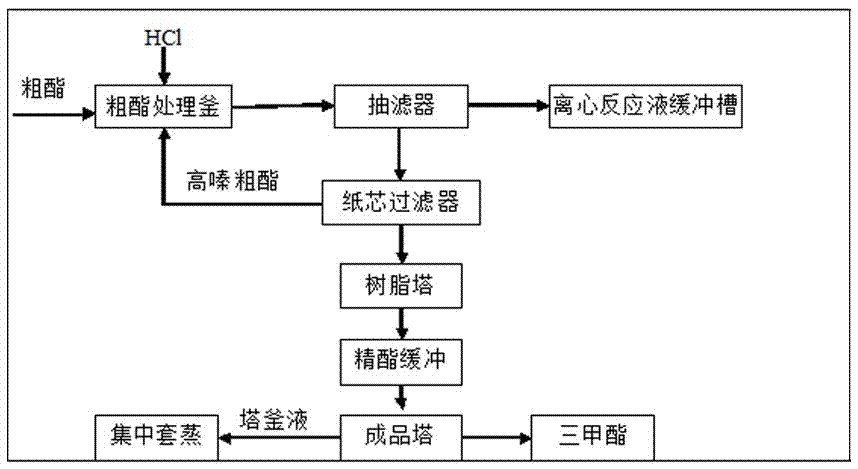

Image

Examples

Embodiment 1

[0020] The synthetic technique of trimethyl orthoformate, it comprises following operation:

[0021] React post:

[0022] (1) Preparatory work

[0023] 1. Check whether the motor is in a normal state, jog the stirring to check the direction of rotation, use the frequency converter to adjust the stirring speed, and check whether the mirror light is powered on.

[0024] 2. Check the bottom valve and feeding valve of the reactor to see if they are closed, and whether the switching status of other valves is correct.

[0025] 3. ③ Check whether the control valves, electronic scales and instruments are sensitive and easy to use, and whether the on-site data display is consistent and accurate with the central control room.

[0026] 4. Check whether the reactor is clean and dry, whether the brine supply is normal, and whether the tail gas absorption device can be used normally.

[0027] 5. Check whether each raw material measuring tank is prepared, and whether the prepared material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com