Preparation method of tobacco maltose caramel flavor

A technology of maltose caramel and maltose, which is applied in the direction of essential oils/spices, tobacco, application, etc., can solve the problems of negative taste, influence, and restriction of application of caramel for cigarettes, etc., achieve good application effect, avoid safety risks, The effect of improving the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of maltose caramel spice for tobacco, the steps are as follows:

[0019] (1) Dissolve 750g of maltose powder in 250g of 100°C distilled water, put it in a 130°C and 3Mpa nitrogen-protected autoclave to react for 2 hours after the dissolution is complete; after the reaction, cool down to normal temperature and pressure, and take out the obtained reaction Product, sealed and preserved.

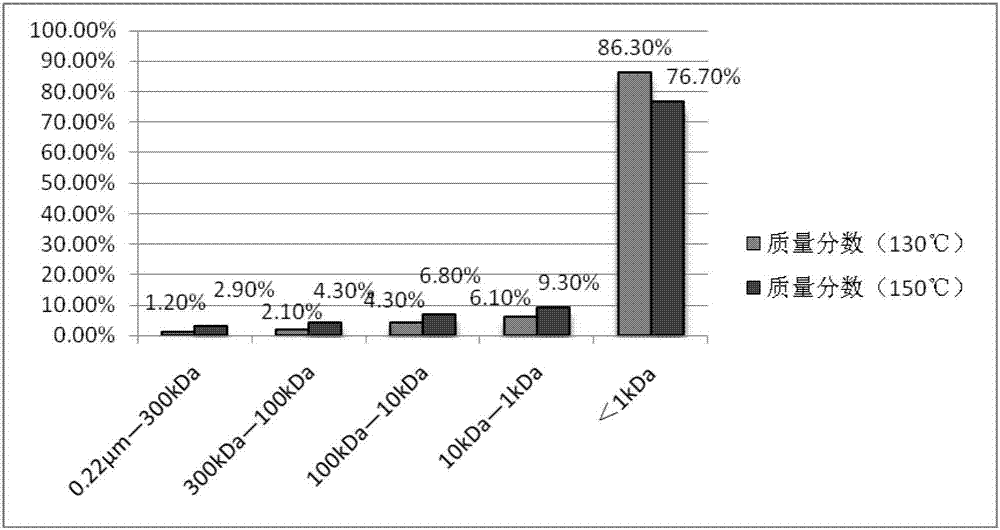

[0020] (2) add distilled water of equal quality to the reaction product obtained in step (1) and dilute, then adopt spiral flat membrane filtration equipment to carry out multistage ultrafiltration to the reaction product after dilution, and the ultrafiltration membrane stages of each level are respectively: 0.22μm-300kDa (first grade), 300kDa-100kDa (second grade), 100kDa-10kDa (third grade), 10kDa-1kDa (fourth grade) and <1kDa (fifth grade).

[0021] Distilled water was used to wash the first to fourth grades of retentate through the membrane, and each grade of ret...

Embodiment 2

[0025] A method for preparing maltose caramel flavoring for tobacco, the steps of which are the same as in Example 1, except that the reaction temperature in step (1) is 150°C, and the first to fifth grade samples obtained are marked as B1-B5.

[0026] Each component in embodiment 1 and embodiment 2 is weighed, and the mass distribution of components at all levels is shown in figure 1 . Depend on figure 1 It can be seen that the components with a molecular weight of less than 1kDa are the most important components, and the molecular weight distribution of maltose caramel prepared by different processes is obviously different, and has a certain mass fraction (can provide a single component of sufficient quality for subsequent compounding and fragrance use) ), thus supporting the flexibility and achievability of compound fragrance in terms of data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com