A method for continuously synthesizing geranyl butyrate with enzyme catalysis in circulating fluidized bed

A technology of geranyl butyrate and fluidized bed, which is applied in biochemical equipment and methods, methods for supporting/immobilizing microorganisms, biochemical instruments, etc., can solve problems such as unspecified experimental methods and no follow-up reports, and achieve reaction Effects of mild conditions, increased yield and efficiency, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

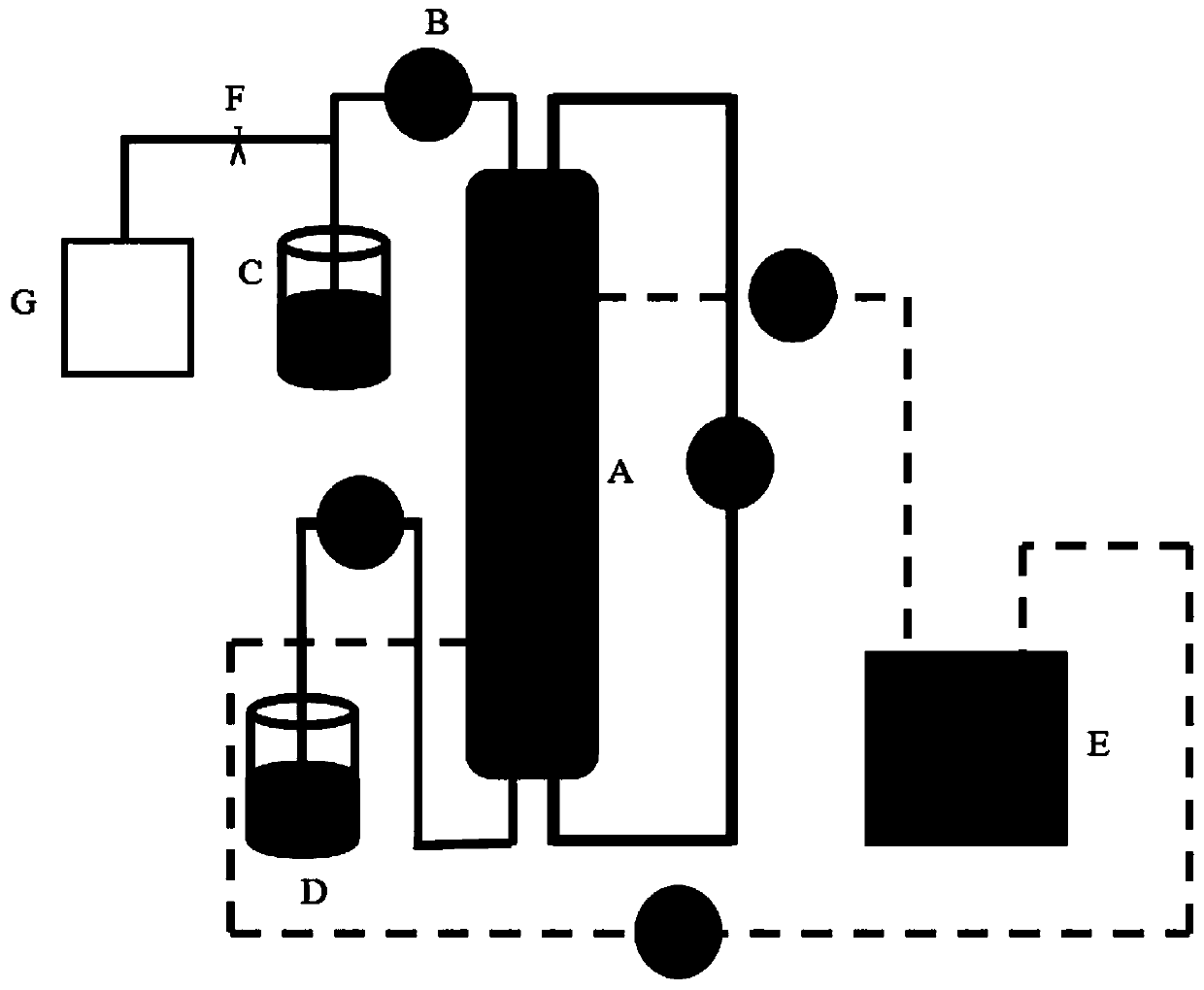

[0047] Embodiment 1: circulating fluidized bed reactor

[0048] Circulating fluidized bed reactor of the present invention, such as figure 1 shown. Its main body consists of fluidized bed body (A), constant flow pump (B), liquid storage tank (C), feed tank (D), constant temperature water bath (E), water stop clamp (F), on-line detector (G ), wherein the fluidized bed body (A) has an interlayer, and a constant temperature water bath (E) supplies circulating water at a certain temperature to maintain a constant temperature in the bed. There are two pipes on the upper and lower sides respectively. The lower right side in the figure is the inlet of the fluidized medium, and the upper part is the outlet of the fluidized medium. They are connected by a constant flow pump with a large flow rate to form a circulation loop to maintain the fluidized state; the lower left side As the feed liquid inlet, a constant flow pump with a small flow rate is used to feed the bed from the feed ta...

Embodiment 2

[0050] Embodiment 2: continuous production process flow optimization

[0051] Geranyl butyrate was synthesized in a circulating fluidized bed reactor with butyric acid and geraniol as raw materials and lipase as a catalyst.

[0052] A lipase-catalyzed continuous synthesis method for synthesizing geranyl butyrate. The present invention studies the effects of substrate concentration, substrate molar ratio, lipase addition, bed expansion ratio, and feeding and discharging speed on the esterification rate.

[0053] Operation of the circulating fluidized bed reactor ( figure 1 ):

[0054] The volume of the reactor is 26mL, and a certain amount of lipase is placed in it. Firstly, there is water circulation in the jacket of the reactor and an external constant temperature water bath is connected to control the temperature of the reaction system. Then use a constant flow pump to feed the feed liquid with a certain molar ratio of acid to alcohol into the reactor and circulate it to ...

Embodiment 3

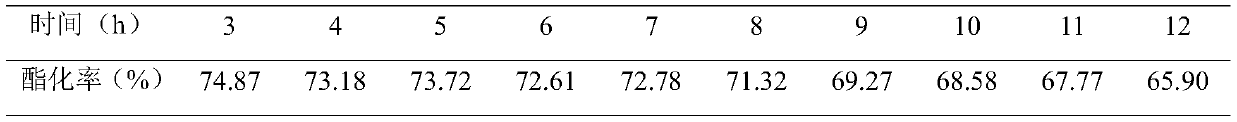

[0062] The volume of the reaction system is 26mL, the concentration of butyric acid in the raw material solution is 0.03mol / L, the concentration of geraniol is 0.03mol / L, the solvent is n-heptane, the amount of lipase added is 7U / mL, and the bed expansion ratio is 1.4. The temperature was 45°C, and after batch reaction for 4 hours, the raw material liquid entered the reactor at a flow rate of 0.10 mL / min, and reacted for 12 hours. The esterification rate of geranyl butyrate is shown in the following table:

[0063] The esterification rate of geranyl butyrate under different continuous reaction times of table 1

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com