Mechanical sensor-based intelligent elastic rod type fastener set

A pressure sensor and sensor technology, applied in the direction of instruments, fixed rails, measuring instruments, etc., can solve the problems of difficult fixing of movable rails and inconvenient movement control of movable rails, so as to reduce maintenance difficulty and cost, and avoid rapid failure , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

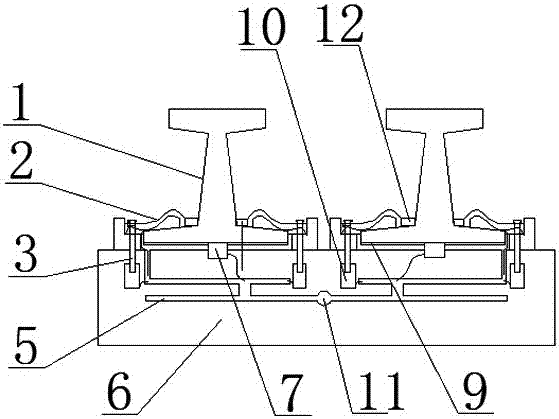

[0019] Such as figure 1 As shown, in this embodiment, a smart elastic fastener group based on a mechanical sensor is suitable for fixing the track at the turnout, including being arranged on both sides of the rail 1, connected with the spike 3 and pressed against the rail 1 The elastic clip 2 on the top, the spike 3 is connected with the base 6 arranged under the rail 1, including the pressure sensor 7 arranged under the rail 1 and capable of sensing the pressure of the rail 1, and the pressure sensor 7 is connected to the circuit through the pressure sensor. The electromagnetic force generator 10 connected; the electromagnetic force generator 10 is connected with the spike 3; the electromagnetic force generator 10 and the pressure sensor 7 are arranged in the base 6; the electromagnetic force generator 10 passes through The main wire is connected to the grid. Described electromagnetic force generator 10 comprises electromagnet and the processor that is electrically connected...

Embodiment 2

[0022] On the basis of the above embodiments, in this embodiment, the base 6 is provided with a circuit groove 5 for installing the connection circuit of the pressure sensor. By accommodating the pressure sensor connection circuit in the circuit slot 5, the influence of environmental factors on the wires can be reduced, the aging of the wires can be delayed, and the risk of wires being run over and damaged by trains can be prevented from being disorderly arranged. In this embodiment, other parts not described are the same as those in the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0024] On the basis of the above-mentioned embodiments, in this embodiment, a main wire hole 11 parallel to the rail 1 and used for installing main wires is provided in the base 6 . In this way, it is convenient to place the main wire in the main wire hole 11 to reduce the aging of the main wire caused by environmental factors, and to avoid the main wire being entangled with the track, resulting in damage to the main wire and leakage of electricity. In this embodiment, other parts not described are the same as those in the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com