Hypsizigus marmoreus cultivation method

A cultivation method and technology for shimeji mushrooms, which are applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve the problem of the lack of scientific and reliable judgment indicators and parameters for the maturity of shimeji mushrooms in industrialized cultivation, and affect the stable production of shimeji mushroom enterprises. It can improve the stability and market competitiveness, improve the fruiting output and production efficiency, and standardize the production and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Method for judging the maturity of Shimeji mushroom bag

[0029] 1 Sampling is sample preparation

[0030] Randomly select 3 kinds of unknown batches of real shimeji mushroom production fungus packets from the real shimeji mushroom manufacturer, each of which takes 20 packs, of which 10 packs are used for fruiting and 10 packs are used for physical and chemical properties testing. Divide it into upper, middle, and lower heights, crush them separately, and set aside for testing.

[0031] 2 Determination of the amount of water contained in bacteria

[0032] Weigh 20 g of cultivation material in a petri dish, dry at 80°C for 6 hours, cover the petri dish, take it out, cool to room temperature, and weigh; put it in an oven and dry it again for 0.5h, then take it out and weigh it again until the quality is poor. More than 0.06g, recorded as m n , The previous weighing is m n-1 . Water content= .

[0033] 3 Determination of pH

[0034] Accurately weigh 10 g of culture mat...

Embodiment 2

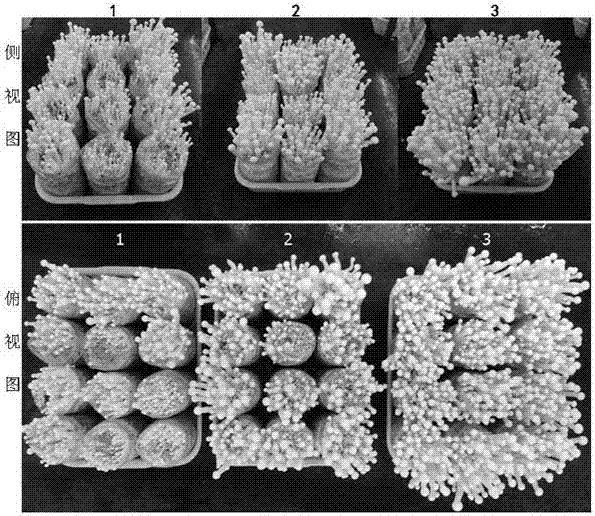

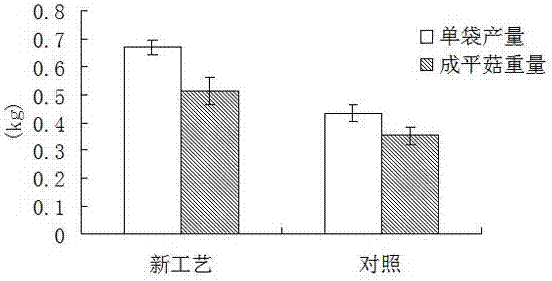

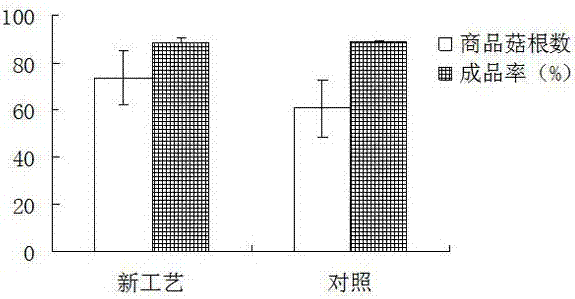

[0043] Example 2 (control)

[0044] (1) Cultivation material configuration: 35 parts of cottonseed hulls, 35% of wood chips, 25 parts of bran, 5 parts of corn flour, 1 part of quicklime, the bag size is 18.5cm×35cm, and the moisture content is 65%. At 1.1kg. Sterilize the filled bacteria bag in time, autoclave at 121°C for 3 hours.

[0045] (2) Inoculation: Before inoculation, the original seed should be expanded to meet the needs of subsequent inoculation. The strains were selected according to the maturity standard in Example 1. When the temperature of the material drops below 28°C, use an inoculator to access the bacteria under aseptic conditions.

[0046] (3) Bacteria: The bacteria bag after inoculation should be moved into the culture room in time. The temperature of the bacteria culture room is controlled at 25°C, and the relative humidity of the air is below 70%. At the same time, ventilation management should be strengthened to prevent the hypoxia in the bag from causing ...

Embodiment 3

[0051] Example 3 (Method of the present invention)

[0052] (1) Cultivation material configuration: Cultivation material contains the following raw materials by weight: 35 parts of cottonseed hulls, 35 parts of wood chips, 25 parts of bran, 5 parts of corn flour, 1 part of quicklime, moisture content of 60-65%, bagging specifications It is 20cm×35cm, and the water content is 60-65%. The amount of each bag is controlled at 1.35kg to improve the packing tightness; sterilize the filled bacteria bag in time, and autoclave at 121℃ for 3 hours;

[0053] (2) Inoculation: Before inoculation, the original species should be expanded and cultivated to meet the needs of subsequent inoculation; strains should be selected according to the maturity standard in Example 1; when the material temperature drops below 28 ℃, the Under the conditions, use an inoculator to connect the bacteria; each bag of bacteria is connected to 40 bags, and the single bag of bacteria weighs 1.05kg;

[0054] (3) Variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com