Multi-zone oxidizing process and device for ammonia process of desulfurization of smoke

A technology of ammonia desulfurization and oxidation device, which is applied in the chemical industry, gas treatment, separation methods, etc. It can solve the problems of difficult reconstruction project construction, lagging aerosol treatment process, and poor oxidation effect of oxidation tank, so as to eliminate flue gas Trailing and falling, reducing the generation of aerosols, good defogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

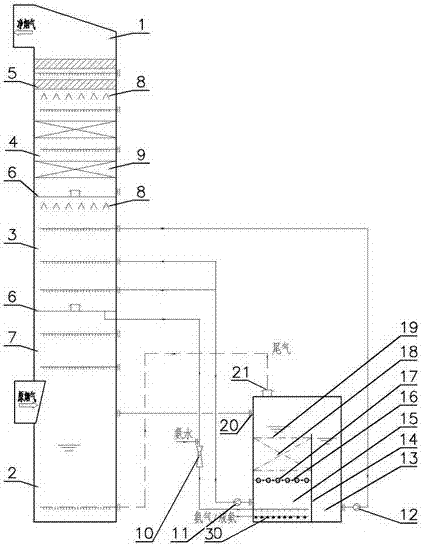

[0038] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0039] The technological process and device of the present invention are based on the principles that ammonium sulfite absorbs sulfur dioxide to generate ammonium bisulfite, ammonium bisulfite reacts with ammonia to generate absorbent ammonium sulfite, and oxidizes ammonium sulfite to generate stable ammonium sulfate.

[0040] In the flue gas ammonia desulfurization multi-zone oxidation device of the present invention, the flue gas passes through the concentrated cooling section 2, the absorption section 3, and the water washing section 4 separated by the gas-liquid separation disc 6 in the desulfurization tower 1 from bottom to top, and then passes through After the dehydration and mist removal section 5 composed of multi-stage mist eliminator 8 at the outlet of desulfurization tower 1, the clean flue gas is discharged.

[0041] The gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com