Microcolumn enrichment sample introduction method

A sampling and enrichment technology, applied in the direction of sampling, instruments, analysis materials, etc., to achieve high enrichment multiples, avoid measurement errors, and save the effect of concentration steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

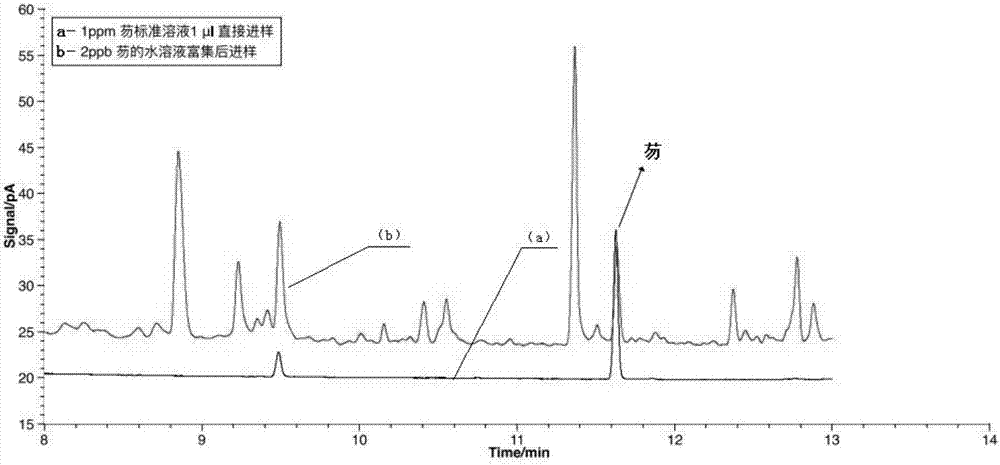

[0040] In this example, polycyclic aromatic hydrocarbon sample fluorene was used as the analysis target to investigate the enrichment effect of the method

[0041] (1) Preparation of Microextraction Column Syringes

[0042] 1. Pretreatment of capillary

[0043] (1) Wash the quartz capillary (320 μm, I.D.) with 1mol / L NaOH solution at a flow rate of 0.1mL / min for 2 hours, fill the column with NaOH solution, seal both ends with silicone rubber, and place it in a gas chromatography column oven at 50°C for reaction 2h;

[0044] (2) Rinse with ultrapure water until neutral at a flow rate of 0.2mL / min; then rinse with 1mol / L HCl at a flow rate of 0.1mL / min for 1 hour, then wash with ultrapure water until neutral;

[0045] (3) Then dry at 160° C. with nitrogen for 10 h.

[0046] 2. Preparation of Octyl Microextraction Columns

[0047] Add 140 μL of tetraethoxysilane (TEOS) and n-octyltriethoxysilane (C8-TEOS) to a mixed solution of 300 μL of methanol, 20 μL of water and 20 μL of ...

Embodiment 2

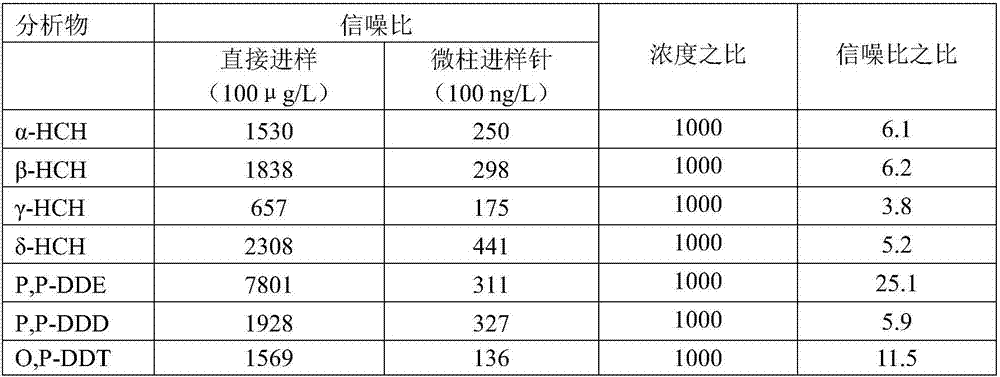

[0060] In this example, 7 kinds of organochlorine pesticides are used as the application results of the investigation method for the analysis target

[0061] (1), preparation of microextraction column injection needle: same as embodiment 1;

[0062] (2), sample analysis

[0063] 1. Sample: Use 7 kinds of organochlorine pesticides (α-HCH, β-HCH, γ-HCH, δ-HCH, P, P-DDE, P, P-DDD and O, P-DDT) to make the concentration 100ng / L mixed aqueous solution was used as a sample solution; the above-mentioned 7 kinds of organochlorine pesticides were used to prepare a dichloromethane solution with a concentration of 100 μg / L, which was used as a control group.

[0064] 2. Sample pretreatment and sample injection: same as implementation case 1

[0065] 3. Analysis method

[0066] Analytical instrument: gas chromatograph with mass spectrometry detector (GC-MS).

[0067] Main chromatographic conditions: Injection port temperature 250°C, injection in splitless mode for 2 minutes. Temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com