Method for cutting glass by using femtosecond laser

A technology of femtosecond laser and femtosecond laser, which is applied in the direction of glass production, glass manufacturing equipment, glass cutting device, etc., can solve the problems of micro-cracks and edge chipping easily, so as to solve edge chipping, improve cutting yield, simplify Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

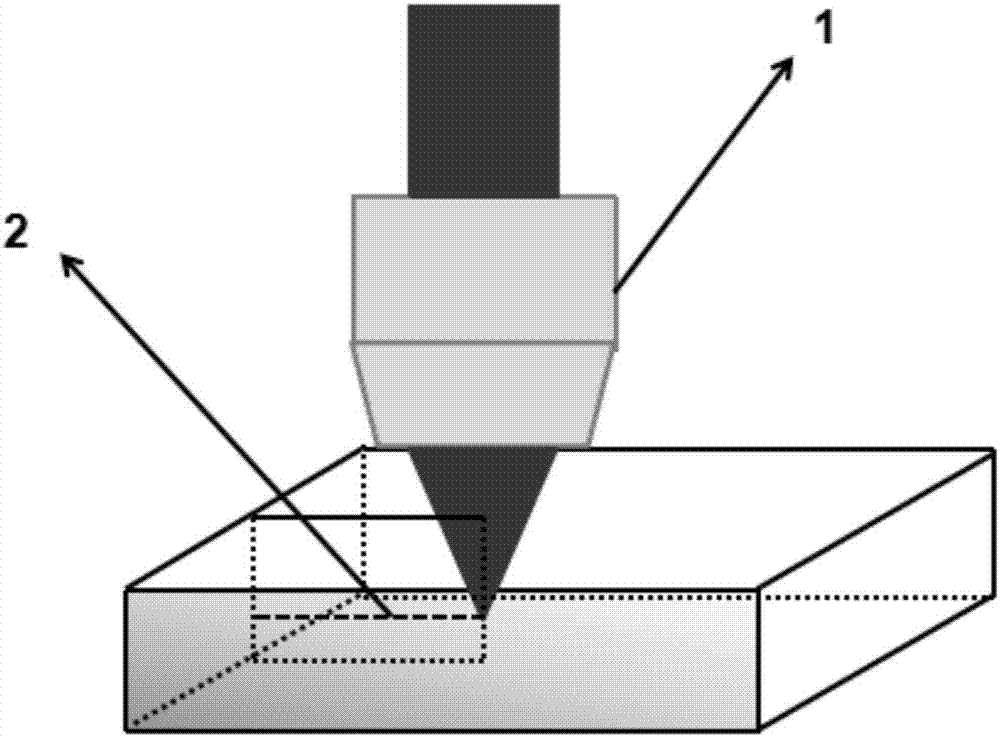

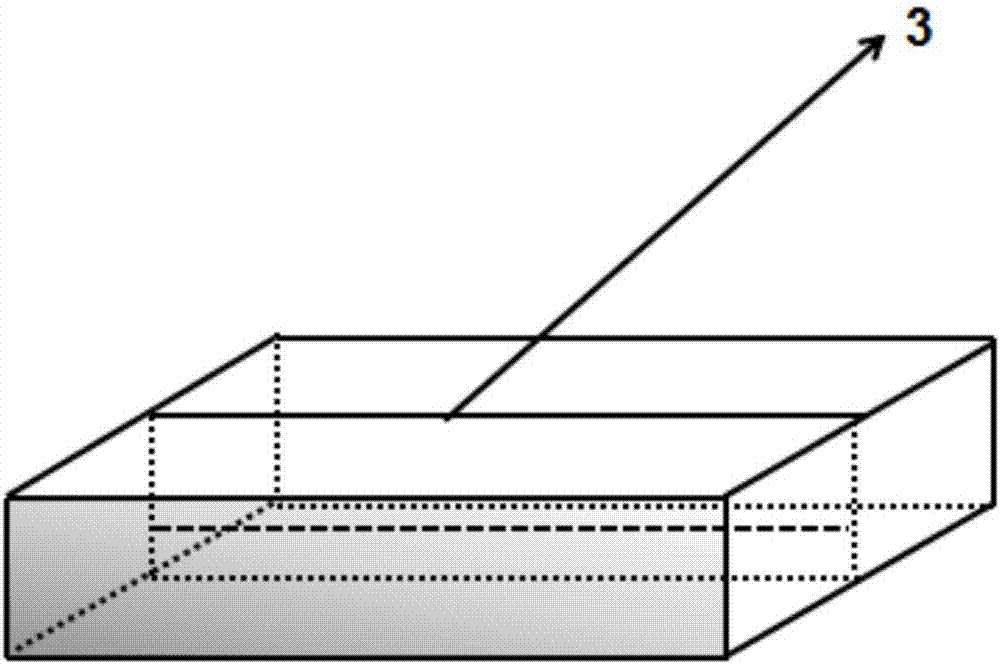

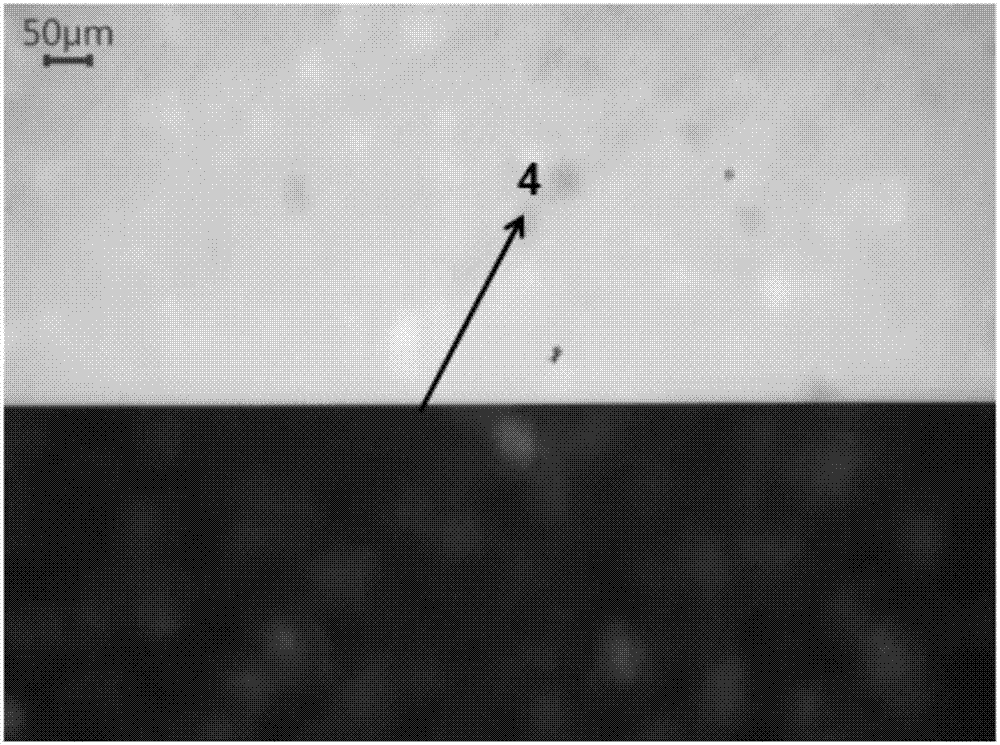

[0034] Such as Figure 1 to Figure 3 As shown, the specific process of femtosecond laser cutting glass is as follows;

[0035] (1) Place a glass slide with a relatively flat surface on the XYZ horizontal workbench of the three-dimensional mobile platform;

[0036] (2) Move the three-dimensional platform so that the focal point is on the surface of the slide;

[0037] (3) Place a glass sample with a size of 60mm×120mm and a thickness of 0.33mm on a glass slide, and move the three-dimensional platform so that the focal point is at a distance of 130 μm from the lower surface of the glass;

[0038] (4) The femtosecond laser with a wavelength of 520nm, a pulse width of 250fs, a pulse repetition rate of 100kHz, and a single pulse energy of 6 μJ is used as the cutting laser beam, and the lens 1 with a numerical aperture of 0.25 is used for focusing. The focused laser beam is directly It is incident on the inside of the glass workpiece, and the diameter of the focused spot is 5 μm, ...

Embodiment 2

[0041] Embodiment 2 and Embodiment 3 adopt the femtosecond laser and process parameters in Table 1, follow the same working process as Embodiment 1, and the edge quality of the cut glass is better.

[0042] Table 1

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com