Anti-clogging discharging valve

A discharge valve and anti-clogging technology, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of inconvenient operation, inability to flow, poor fluidity of crystals, etc., achieve scientific and reasonable position setting, improve economic benefits, and structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

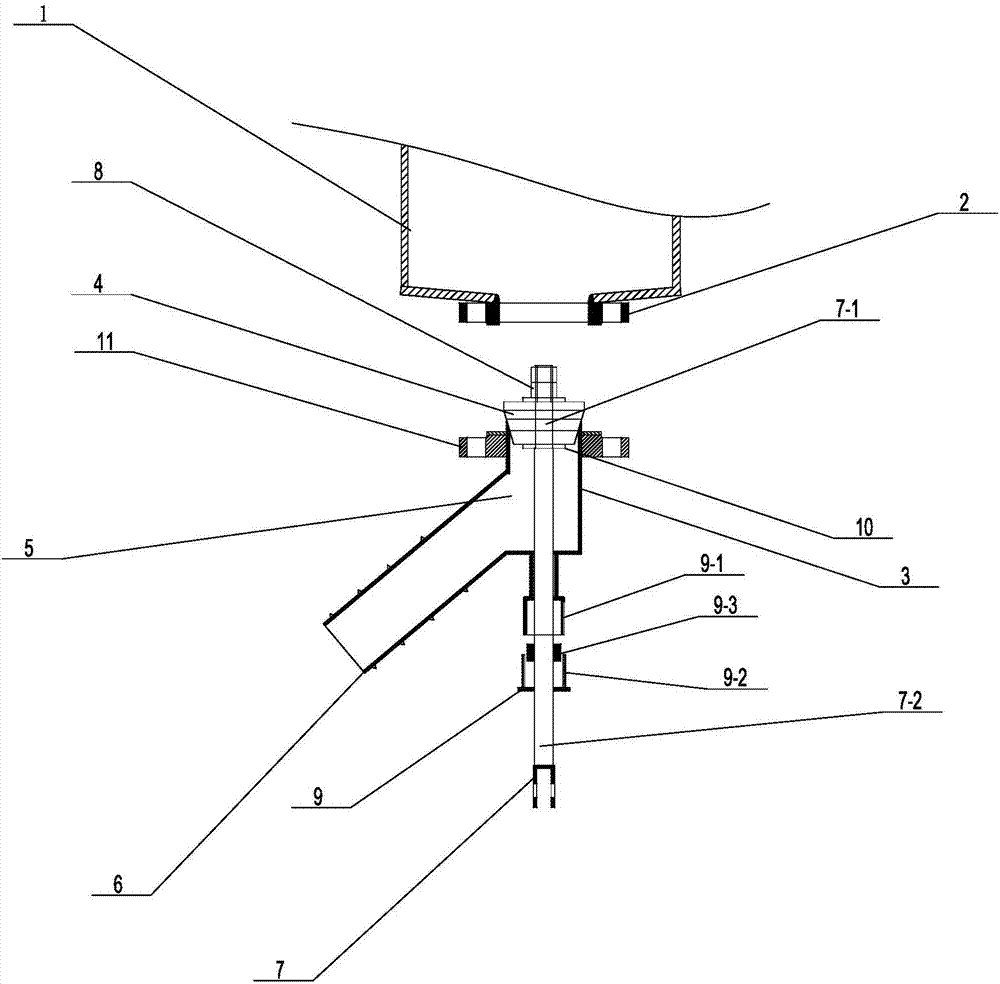

[0015] Such as figure 1 A specific embodiment of the present invention is proposed as shown, the anti-clogging discharge valve includes a flange piece 2 fixed on the discharge port at the bottom of the container 1, and the flange piece 2 is detachably connected with a matching valve body flange piece 11. The valve body flange 11 is arranged on a vertically arranged valve body 3. In this embodiment, the flange 2 is welded under the discharge port at the bottom of the container 1. The flange 2 is There are a number of inner wire bolt holes in a ring shape and symmetrically located in the center of the circle. The structure of the valve body flange 11 corresponds to the structure of the flange 2, and the flange 2 is connected to the valve body flange. The piece 11 is fixedly connected by several bolts. The top of the valve body 3 is provided with a rubber plug 4. In this embodiment, the rubber plug 4 is made of polytetrafluoroethylene. The rubber plug 3 is in the shape of a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com