Binocular-stereoscopic-vision-based workpiece detection and three-dimensional measurement system and detection method

A technology of binocular stereo vision and workpiece detection, which is applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of unintelligent size measurement, easy damage to the surface of the workpiece, and low precision, so as to eliminate the influence of light and reduce Edge glitches, effects that improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

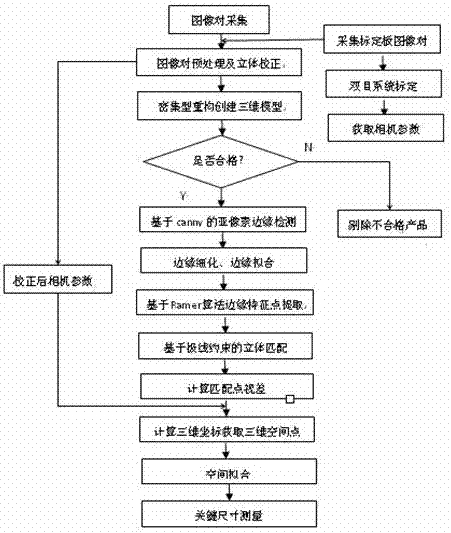

[0032] Embodiments of a workpiece detection method based on binocular stereo vision and an image processing system for realizing the method, so as to realize real-time online detection of workpieces.

[0033] The image processing system structure diagram includes image acquisition module, camera calibration module, image preprocessing module, stereo correction module, three-dimensional information recovery module and detection and measurement module.

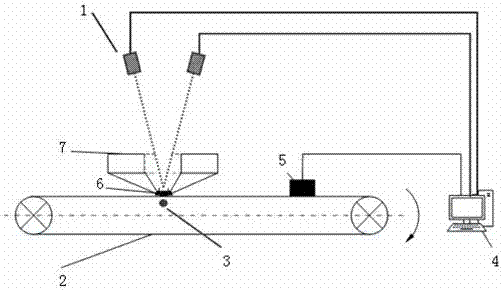

[0034] figure 1 It is a system structure diagram of the present invention, which includes:

[0035] LED ring light, directly above the conveyor belt, provides light source for the CCD camera;

[0036] The workpiece is placed on the conveyor belt and passes through the CCD camera;

[0037] A photoelectric trigger, which is connected with the light source system and the CCD camera, and is used to trigger the work of the CCD camera and the camera;

[0038] The image processing unit is the halcon software installed in the compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com