Combustion chamber combustion instability test measuring method based on image processing

A technology of combustion instability and image processing, applied in image data processing, image enhancement, image analysis, etc., can solve problems such as difficult phase synchronization, high requirements for measurement equipment, and inability to meet measurement needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

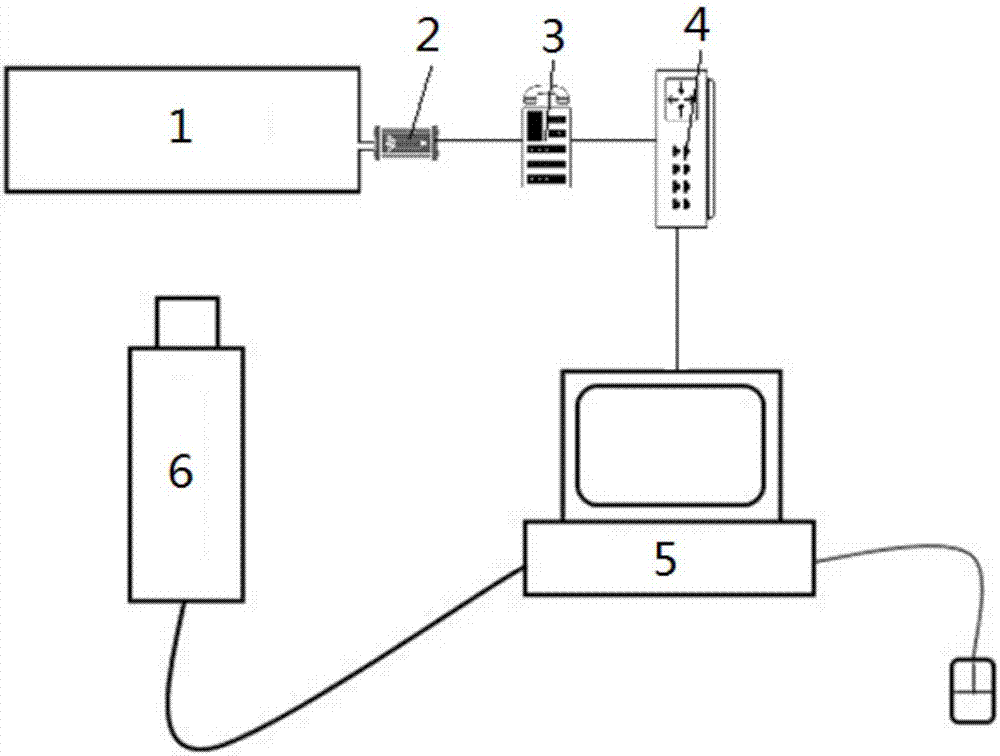

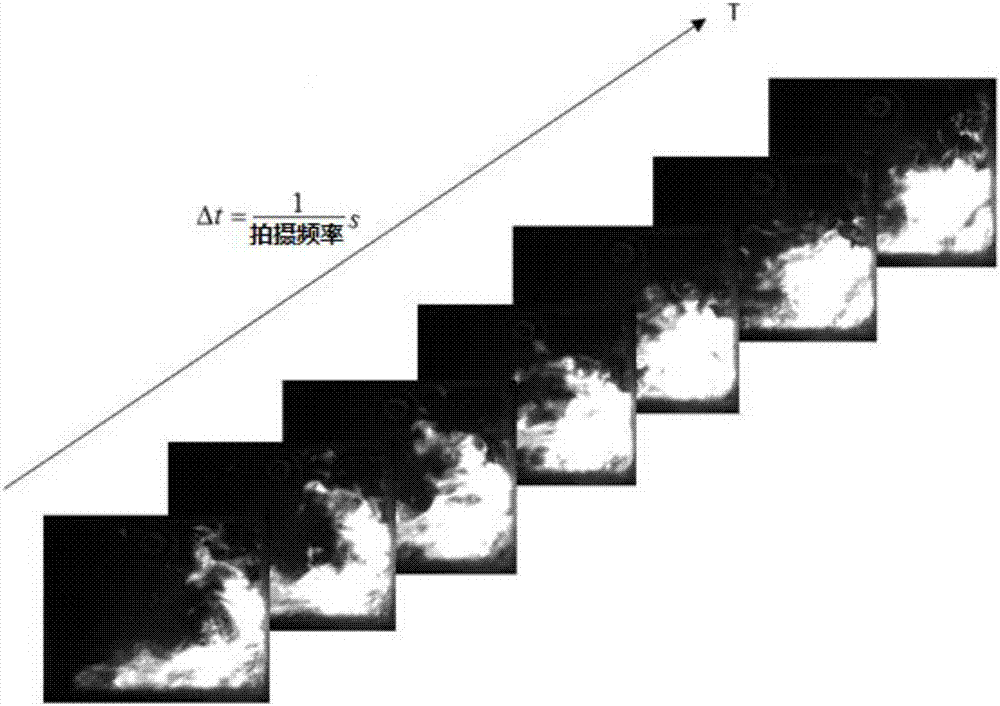

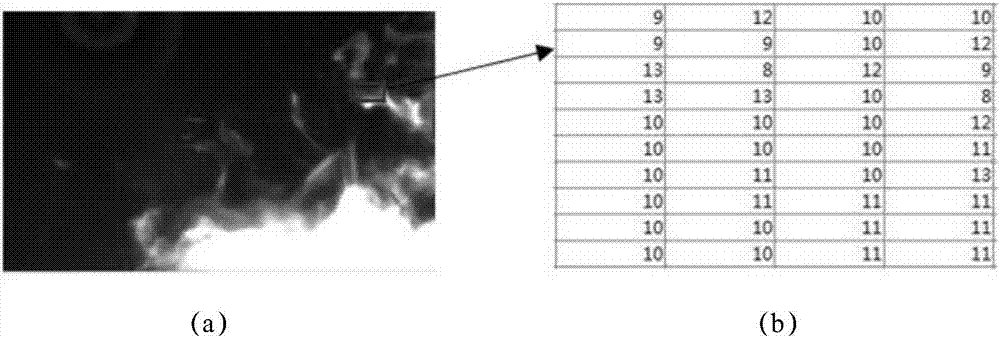

[0028] Combustion chamber combustion instability test measurement system schematic diagram of the present invention is as figure 1 shown. A high-speed camera or other high-speed CCD camera 6 and a filter of a specific wavelength are used to measure the dynamic change process of the flame free radical map at different moments during the unstable combustion process of the combustion chamber 1 . Since the shooting frequency of the high-speed camera can reach 100,000 Hz, it can capture the unstable dynamic change process of combustion at different pulsation frequencies; at the same time, according to the different free radicals concerned in the test measurement, filters at different wavelengths are selected, For example, if you are concerned about the combustion heat release rate of the hydroxyl group, you should choose a filter with the wavelength of the hydroxyl group, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com