Lithium titanate-based lithium ion battery negative electrode, lithium ion battery and formation method of lithium ion battery

An ion battery, lithium titanate technology, applied in battery electrodes, secondary battery charging/discharging, secondary batteries, etc., can solve problems such as only 90%, lithium precipitation safety accidents, low battery design capacity, etc., to improve design The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

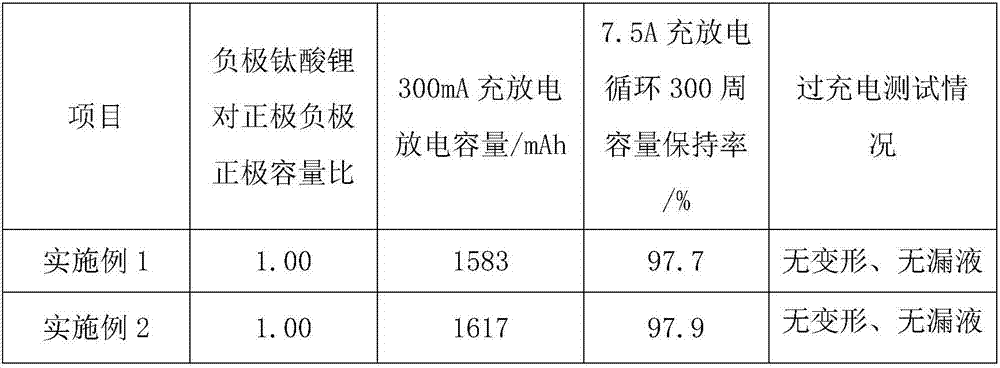

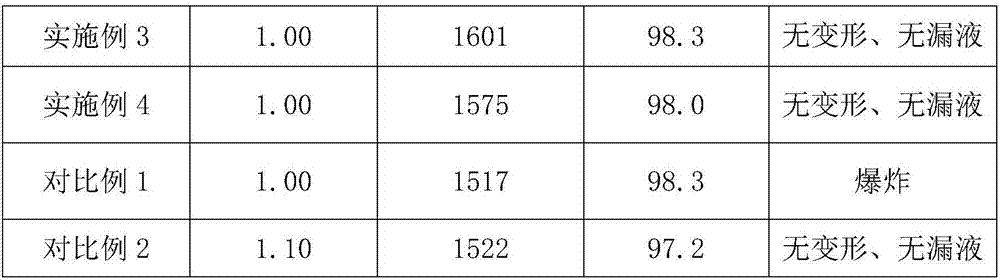

Embodiment 1

[0033] Example 1 (the addition amount of the additive in this example is about 0.2wt% of the lithium titanate active material)

[0034] Lithium-ion battery negative electrode production:

[0035] Add 13.5g PVDF to 550mL NMP, fully stir to dissolve; add 4.5g conductive carbon black and stir for 30 minutes; add 449.1g lithium titanate material (capacity 165mAh / g), 0.9g commercially available silicon oxide powder (half-cell measured first charge Capacity 2380mAh / g, first cycle efficiency 33.7%), stirring for 60 minutes. The obtained slurry was coated on an aluminum foil with a thickness of 20 micrometers, oven-dried at 120 degrees, and the coating weight gain was 220 g / m2 (both sides).

[0036] Compacted according to density 2.0, cut into a width of 57mm.

[0037] Lithium-ion battery production:

[0038] Add 12g PVDF to 350mL NMP, fully stir to dissolve; add 12g conductive carbon black and stir for 30 minutes; add 800g commercially available NMC622 ternary positive electrode m...

Embodiment 2

[0046] Embodiment 2 (the addition amount of the additive described in this embodiment is about 1wt% of the lithium titanate active material)

[0047] Production of lithium titanate-based lithium-ion battery negative electrode:

[0048] Add 13.5g PVDF to 550mL NMP, fully stir to dissolve; add 4.5g conductive carbon black and stir for 30 minutes; add 445.5g lithium titanate material (capacity 165mAh / g), 4.5g commercially available tin dioxide (half-cell measured first charge capacity 1350mAh, first week efficiency 31%) powder, stirred for 60 minutes. The obtained slurry was coated on an aluminum foil with a thickness of 20 microns, and dried in an oven at 120 degrees, and the coating weight gain was 220 g / m2 (both sides).

[0049] Compacted according to density 2.0, cut to a width of 57mm

[0050] Production of 18650 lithium-ion battery:

[0051] Step is with embodiment 1.

Embodiment 3

[0052] Example 3 (the addition amount of the additive in this example is about 2wt% of the lithium titanate active material)

[0053] Add 13.5g PVDF to 550mL NMP, fully stir to dissolve; add 4.5g conductive carbon black and stir for 30 minutes; add 441g lithium titanate material (capacity 165mAh / g), 9g commercially available nickel oxide powder (actually measured first charge capacity 980mAh / g , first week efficiency 38.1%), stirred for 60 minutes. The obtained slurry was coated on an aluminum foil with a thickness of 20 microns, and dried in an oven at 120 degrees, and the coating weight gain was 220 g / m2 (both sides).

[0054] Compacted according to density 2.0, cut into a width of 57mm.

[0055] Production of 18650 lithium-ion battery:

[0056] Step is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com