Preparation method of heat-resistant high-breathability composite coated diaphragm

A highly breathable and coating technology, applied in electrical components, structural parts, secondary battery repair/maintenance, etc., can solve problems such as unstable diaphragm size, unbalanced internal resistance, battery disintegration, etc., to suppress adverse side reactions , Increase peel strength and heat resistance, improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

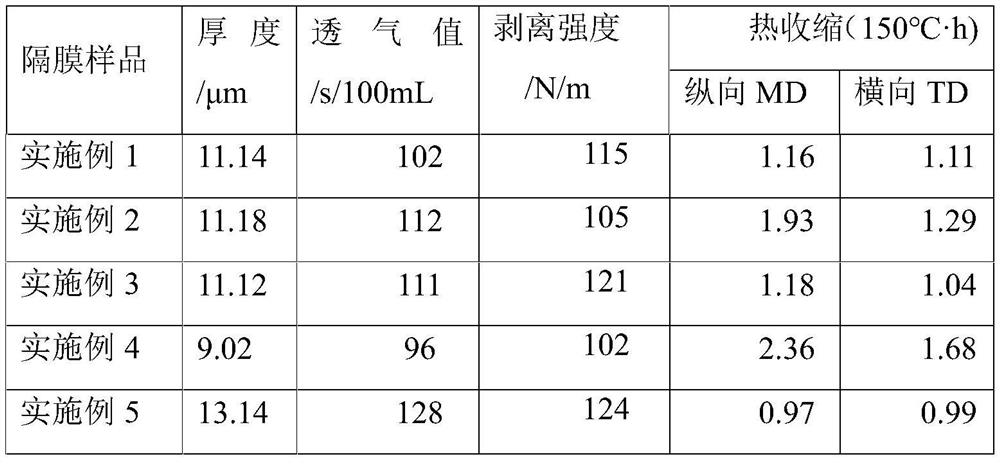

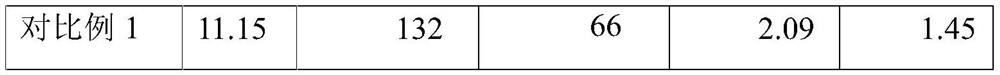

Examples

Embodiment 1

[0025] (1) Preparation of MOF coating slurry

[0026] Dissolve 0.88g of copper nitrate trihydrate and 0.4g of isophthalic acid in 150mL of ethanol respectively, mix the two after complete dissolution, stir at room temperature for 30-120min or ultrasonically for 20-50min to obtain a precursor dispersion. The resulting dispersion was washed with ethanol and dried in a vacuum oven at 160 °C for 12 h to obtain the MOF product.

[0027] Add MOF and PVDF into NMP at a mass ratio of 2:1, stir and disperse for 60 minutes to obtain a coating slurry.

[0028] (2) Preparation of hydrotalcite coating slurry

[0029] First, mix 60 parts of ultrapure water and 0.5 parts of dispersant evenly according to the mass ratio, then add 30 parts of magnesium aluminum hydrotalcite, and then add 6 parts of thickener after high-speed stirring and mix evenly; Grinding with a sand mill, finally adding 3 parts of binder and 0.1 part of wetting agent and stirring evenly to obtain a hydrotalcite coating s...

Embodiment 2

[0033] (1) Preparation of MOF coating slurry

[0034] Dissolve 0.88g of copper nitrate trihydrate and 0.4g of isophthalic acid in 150mL of ethanol respectively, mix the two after complete dissolution, stir at room temperature for 30-120min or ultrasonically for 20-50min to obtain a precursor dispersion. The resulting dispersion was washed with ethanol and dried in a vacuum oven at 160 °C for 12 h to obtain the MOF product.

[0035] Add MOF and PVDF to NMP at a mass ratio of 1.5:1, stir and disperse for 60 minutes to obtain a coating slurry.

[0036] (2) Preparation of hydrotalcite coating slurry

[0037] First, mix 60 parts of ultrapure water and 0.5 parts of dispersant evenly according to the mass ratio, then add 30 parts of magnesium aluminum hydrotalcite, and then add 6 parts of thickener after high-speed stirring and mix evenly; Grinding with a sand mill, finally adding 3 parts of binder and 0.1 part of wetting agent and stirring evenly to obtain a hydrotalcite coating s...

Embodiment 3

[0041] (1) Preparation of MOF coating slurry

[0042] Dissolve 0.88g of copper nitrate trihydrate and 0.4g of isophthalic acid in 150mL of ethanol respectively, mix the two after complete dissolution, stir at room temperature for 30-120min or ultrasonically for 20-50min to obtain a precursor dispersion. The resulting dispersion was washed with ethanol and dried in a vacuum oven at 160 °C for 12 h to obtain the MOF product.

[0043] Add MOF and PVDF into NMP at a mass ratio of 3:1, stir and disperse for 60 minutes to obtain a coating slurry.

[0044] (2) Preparation of hydrotalcite coating slurry

[0045] First, mix 60 parts of ultrapure water and 0.5 parts of dispersant evenly according to the mass ratio, then add 40 parts of magnesium aluminum hydrotalcite, and then add 6 parts of thickener after high-speed stirring and mix evenly; Grinding with a sand mill, finally adding 3 parts of binder and 0.1 part of wetting agent and stirring evenly to obtain a hydrotalcite coating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com