Open packless deep-well anode ground bed and cathode protection system

An anode ground bed, no filler technology, applied in the field of electrochemical equipment, can solve the problems of high scrap rate, poor protection effect, easy occurrence of gas resistance, etc., and achieve the effect of reducing scrap rate, saving costs and avoiding scrap problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

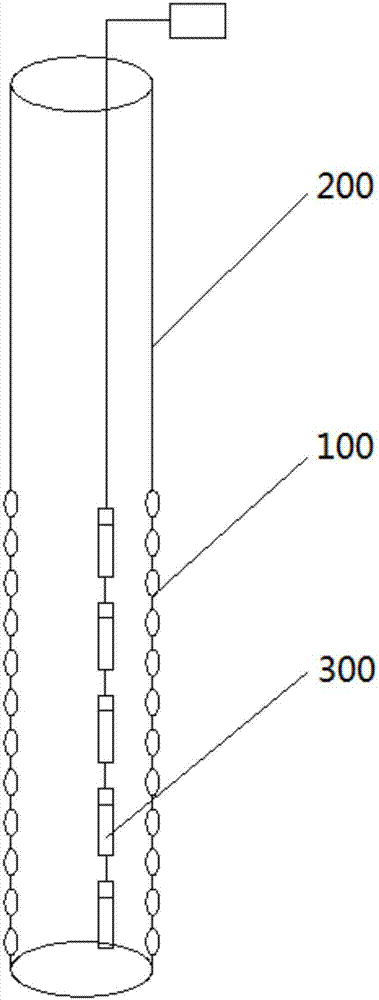

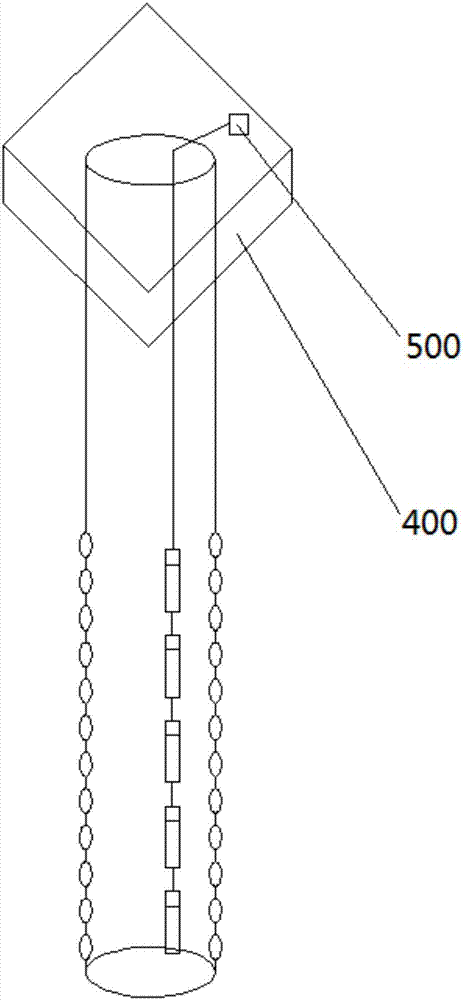

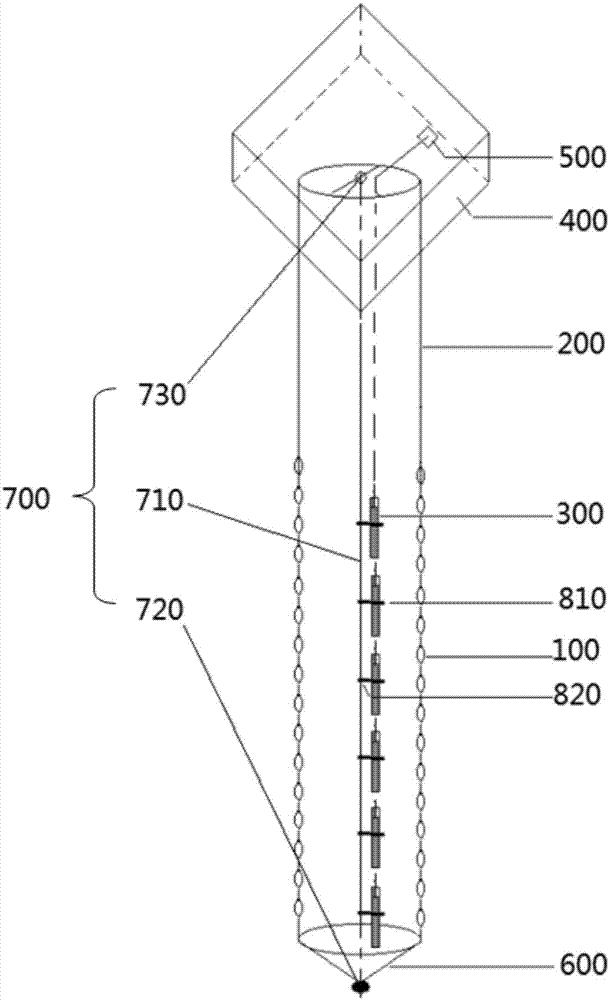

[0030] Such as figure 1 As shown, this embodiment provides an open anode bed without filler, including a screen 100, a wellbore 200 arranged on the upper part of the screen 100 along the axial direction of the screen 100, and an anode arranged in the screen 100 300, specifically:

[0031] The screen 100 and the wellbore 200 are injected with brine.

[0032] The open unfilled deep-well anode bed includes a screen 100, a wellbore 200 and an anode 300. The wellbore 200 is arranged on the upper part of the screen 100, and the wellbore 200 is arranged along the axis of the screen 100 and connected to the screen 100. The anode 300 Set inside the screen pipe 100, the screen pipe 100 and the wellbore 200 are filled with brine. Compared with the prior art, the position where the anode 300 is placed is filled with granular coke, and the part above the anode 300 is filled with Stone or sand, use coke to increase the contact surface of the anode 300, maintain humidity to reduce the resi...

Embodiment 2

[0045] This embodiment provides a cathodic protection system, which includes the open and unfilled deep-well anode bed in Embodiment 1. The cathodic protection system can also include a power supply device and a conductor, etc. The protection current is introduced from the power supply device into the conductor in the soil, and the protection current is sent into the soil through the open and unfilled deep well anode bed, and flows into the protected pipeline through the soil , so that the surface of the pipeline is cathodically polarized, and the current flows from the pipeline into the negative electrode of the power supply device, thereby forming an electrolytic cell. By injecting brine into the screen pipe 100 and the wellbore 200, the anode 300 is filled with brine, and the wellbore 200 is used for direct Exhaust effectively reduces the resistance and avoids the occurrence of gas resistance, making the protection effect better. At the same time, it avoids the scrapping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com