A kind of filter paper for PM2.5 protective mask and preparation method thereof

A filter paper and filter paper technology, applied in the field of filter paper, can solve the problems of high resistance, attenuated use effect of electret materials, and difficulty in meeting the needs of human breathing comfort and clean air at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

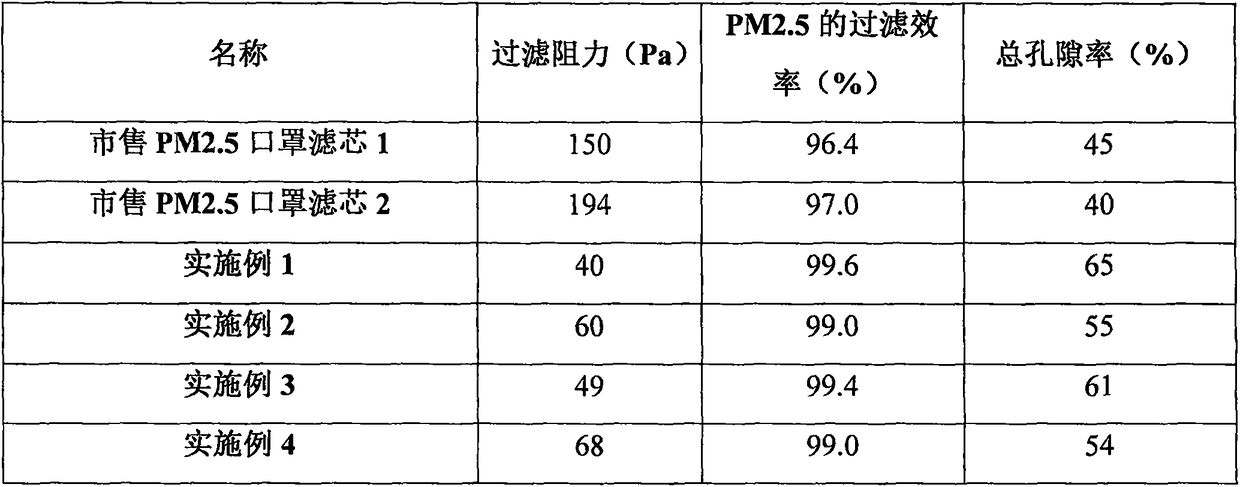

Examples

Embodiment 1

[0021] The present embodiment prepares filter paper for PM2.5 protective mask, comprises the following steps:

[0022] (1) Tencel fiber is beaten by a disc refiner, the refining concentration is 8%, and the gap between the discs is controlled at 0.2 mm.

[0023] (2) After mixing 30 parts of the slurry in step (1) with 30 parts of PET fibers, add 0.5 parts of polyamide polyamine epichlorohydrin resin (PAE) and cationic polyamide in the dual retention system in sequence. 0.08 parts of acrylamide, 0.08 parts of anionic polyacrylamide in the binary retention system, and 40 parts of calcium carbonate filler. Add appropriate amount of water to dilute the slurry, and stir well to mix evenly.

[0024] (3) After the slurry mixture in step (2) is formed by a fourdrinier paper machine or a cylinder paper machine, it is pressed by a shoe press with a nip pressure of 600 N / m, and then enters a drying cylinder for drying. During the process, the density of the filter paper substrate shoul...

Embodiment 2

[0029] The present embodiment prepares filter paper for PM2.5 protective mask, comprises the following steps:

[0030] (1) Tencel fibers are beaten by a disc refiner, the refining concentration is 10%, and the gap between the discs is controlled at 0.2 mm.

[0031] (2) After mixing 40 parts of the slurry in step (1) with 20 parts of PET fibers, add 0.3 parts of polyamide polyamine epichlorohydrin resin (PAE) and cationic polyamide in the binary retention system in sequence. 0.05 parts of acrylamide, 0.05 parts of anionic polyacrylamide in the binary retention system, and 30 parts of calcium carbonate filler. Add appropriate amount of water to dilute the slurry, and stir well to mix evenly.

[0032] (3) After the slurry mixture in step (2) is formed by a fourdrinier paper machine or a cylinder paper machine, it is pressed by a shoe press with a nip pressure of 600 N / m, and then enters a drying cylinder for drying. During the process, the density of the filter paper substrate ...

Embodiment 3

[0037] The present embodiment prepares filter paper for PM2.5 protective mask, comprises the following steps:

[0038] (1) Tencel fibers are beaten by a disc refiner, the refining concentration is 9%, and the gap between the discs is controlled at 0.3 mm.

[0039] (2) After mixing 35 parts of the slurry in step (1) with 35 parts of PET fibers, add 0.3 parts of polyamide polyamine epichlorohydrin resin (PAE), cationic poly 0.10 parts of acrylamide, 0.08 parts of anionic polyacrylamide in the binary retention system, and 35 parts of calcium carbonate filler. Add appropriate amount of water to dilute the slurry, and stir well to mix evenly.

[0040] (3) After the slurry mixture in step (2) is formed by a fourdrinier paper machine or a cylinder paper machine, it is pressed by a shoe press with a nip pressure of 600 N / m, and then enters a drying cylinder for drying. During the process, the density of the filter paper substrate should be increased as much as possible.

[0041] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com