A kind of graphite negative electrode material and preparation method thereof

A graphite negative electrode and raw material technology, applied in chemical instruments and methods, battery electrodes, structural parts, etc., can solve the problems of complex production process, capacity loss, and high production cost, and achieve mature and stable process, shortened capacity loss, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

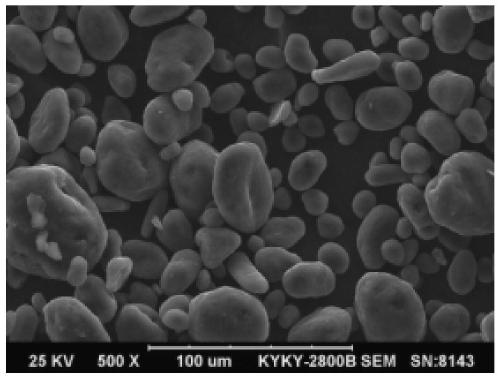

Image

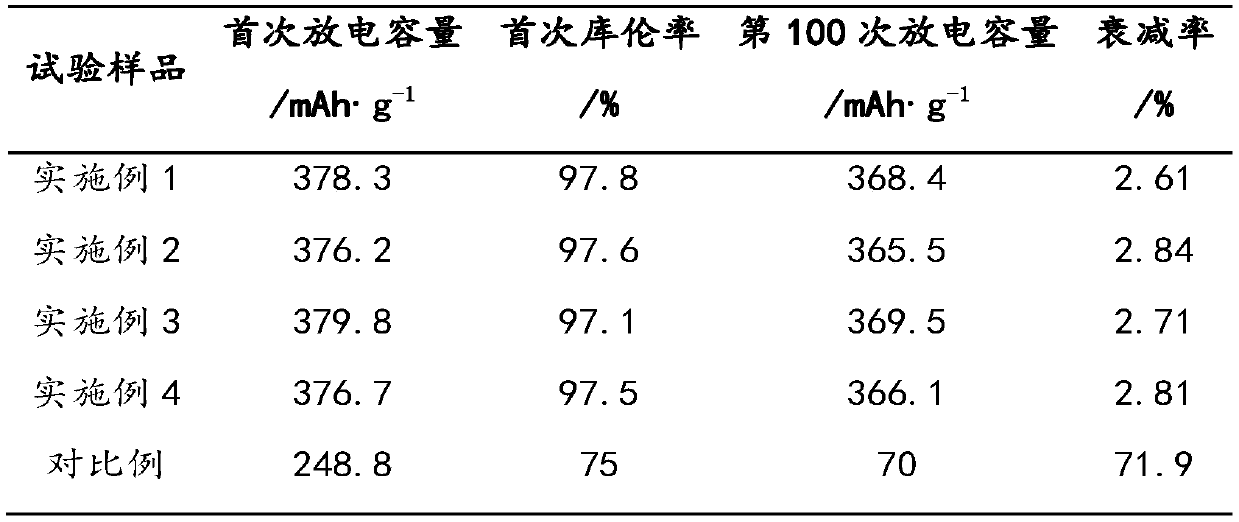

Examples

preparation example Construction

[0034] The first aspect of the present invention provides a kind of preparation method of graphite negative electrode material, comprises the following steps:

[0035] 1. Kneading

[0036] One or more combinations of petroleum coke, pitch coke and resistance material are used as raw materials. Add graphitization catalyst, graphene and binder to raw materials. The addition amounts of the three substances are respectively: the graphitization catalyst accounts for 1-5wt% of the material, the graphene accounts for 1-5wt% of the material, and the binder accounts for 20-40wt% of the material. The raw materials are then kneaded with graphitization catalyst, graphene and binder. Knead the materials evenly in the kneading pot. Through kneading, various raw materials and auxiliary materials (graphitization catalyst, graphene and binder) can be mixed evenly, and the consistency of the product can be improved.

[0037] Preferably, during kneading, the kneading temperature is 160-220°C...

Embodiment 1

[0060] The preparation method of the graphite negative electrode material of the present embodiment is prepared according to the following steps:

[0061] 1. Kneading

[0062] Petroleum coke, pitch coke and resistance material are used as raw materials. 2% graphitization catalyst, 2% graphene and 25% binder are added to the raw materials, and the rest are raw materials. Wherein, the graphite catalyst is borax. The binder is medium temperature modified asphalt. Then the raw materials are kneaded with the graphitization catalyst, graphene and binder at a temperature of 160°C.

[0063] 2. Piecing, first crushing and pressing

[0064] The material obtained after mixing and kneading is subjected to tableting treatment, and the material after tableting is first crushed to 150 mesh, and then pressed with an isostatic press under the conditions of a pressing temperature of 420°C and a pressure of 290 MPa. type processing.

[0065] 3. The first roasting treatment

[0066] The pr...

Embodiment 2

[0076] The preparation method of the graphite negative electrode material of the present embodiment is prepared according to the following steps:

[0077] 1. Kneading

[0078] Petroleum coke and resistance material are used as raw materials. 5% graphitization catalyst, 5% graphene and 40% binder are added to the raw materials, and the rest are raw materials. Wherein, the graphite catalyst is borax. The binder is medium temperature modified asphalt. Then the raw materials are kneaded with the graphitization catalyst, graphene and binder at a temperature of 220°C.

[0079] 2. Piecing, first crushing and pressing

[0080] The material obtained after kneading is subjected to pelletizing treatment, and the pelletized material is crushed for the first time to 240 mesh, and then pressed with an isostatic press under the conditions of a pressing temperature of 350°C and a pressure of 290MPa. type processing.

[0081] 3. The first roasting treatment

[0082] The pressed material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com