Preparation method of lanthanum-ferrite-doped graphite phase carbon nitride composite photocatalyst

A technology of graphitic carbon nitride and lanthanum ferrite, which is applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., achieves a simple preparation method and easy control of preparation conditions , the effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

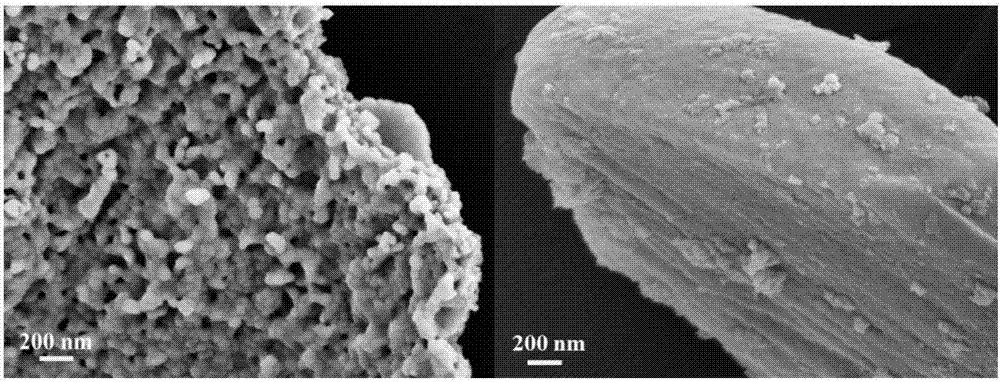

Image

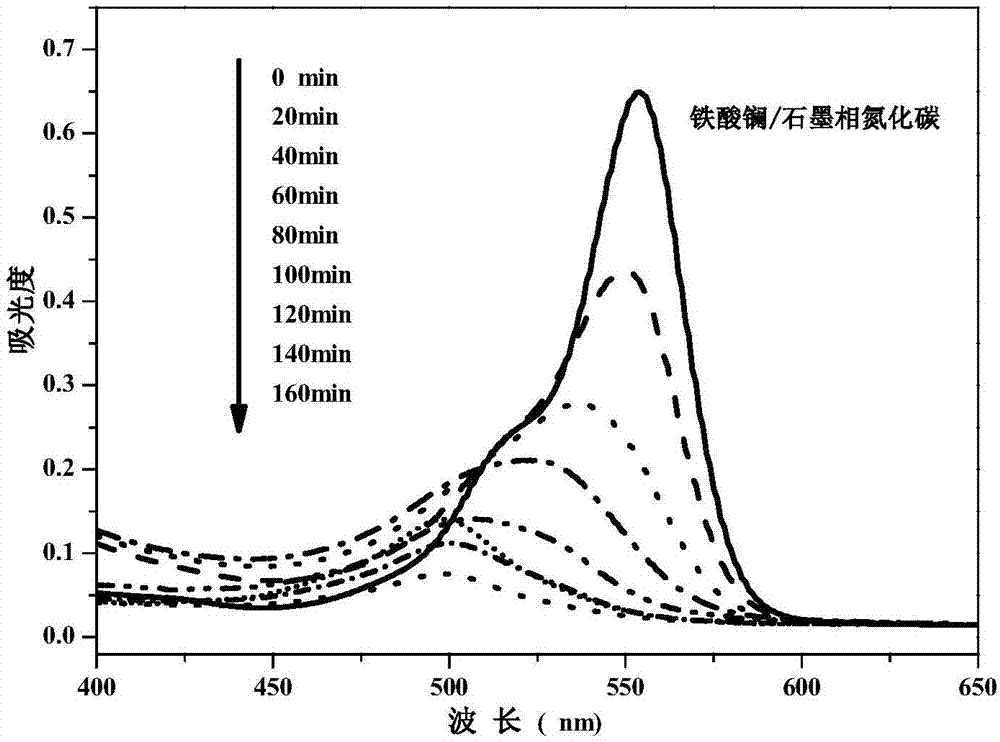

Examples

Embodiment 1

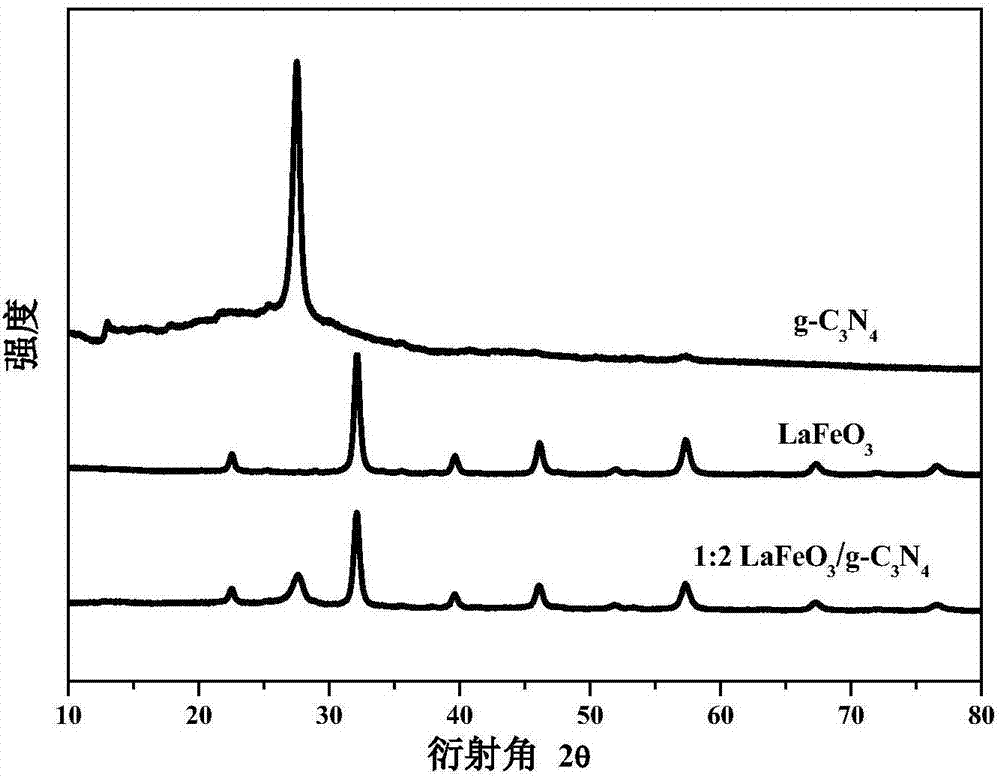

[0021] (1) Graphite phase carbon nitride (g-C 3 N 4 ) preparation: put 5 g of melamine into a crucible, heat to 550° C., heat for 5 hours, cool naturally to room temperature and grind to obtain the product;

[0022] (2) Lanthanum ferrite (LaFeO 3 ) preparation: 3 mol of lanthanum nitrate, 3 mol of ferric nitrate and 3 mol of citric acid were respectively dissolved in 20 solvent I (water:ethanol=1:1), stirred for 20 min, heated to 60° C. for 3 h, until a xerogel was formed, Drying at 100°C for 12h, calcining at 550°C for 5h, cooling naturally to room temperature and grinding to obtain the product;

[0023] (3) Preparation of lanthanum ferrite-doped graphitic carbon nitride composite photocatalyst: 2 g of graphitic carbon nitride (g-C 3 N 4 ) and 1g lanthanum ferrite (LaFeO 3 ) respectively into beakers, put into 20ml of dispersant, and ultrasonic for 30min. Then LaFeO 3 The suspension was added dropwise to the graphite phase carbon nitride suspension, stirred for 12 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com